R&D and Technology

- Home

- Company

- R&D and Technology

LTZC specializes in the research and development of slewing bearings and crossed roller bearings. With over 15 years of experience in precision bearing manufacturing, LTZC ensures that every bearing possesses high load capacity, long service life, and superior rotational accuracy. As a trusted bearing manufacturer and solutions provider, LTZC serves customers in industries such as construction machinery, wind power, mining, industrial automation, and heavy equipment. We offer OEM and custom bearing designs to meet specific operational needs; rigorous quality control, advanced manufacturing processes, comprehensive testing, and ISO-certified production processes ensure product reliability even under the most demanding conditions.

Get a quoteLTZC boasts a professional and experienced bearing R&D team, with each member possessing an average of over 10 years of bearing design and development experience. LTZC invests 20% of its sales revenue in R&D annually. This team possesses deep expertise in key areas such as bearing materials, structural design, load distribution, lubrication, and precision control. Leveraging advanced CAD/CAE modeling, finite element analysis (FEA), and testing technologies, they can accurately predict performance under harsh operating conditions and innovate solutions for complex applications. This ensures that all slewing bearings meet international quality standards, supporting OEM and customized applications, and providing reliable, high-precision slewing bearings for engineering machinery, wind power, mining, automation, and other industrial sectors.

Get a quote

Bearing production equipment

5-meter drilling and milling machine

Used for precision machining of slewing bearing rings, ensuring high accuracy and smooth surface quality.

10-meter gear hobbing machine

Processes slewing bearing gears with excellent precision, guaranteeing stable transmission and reliable performance.

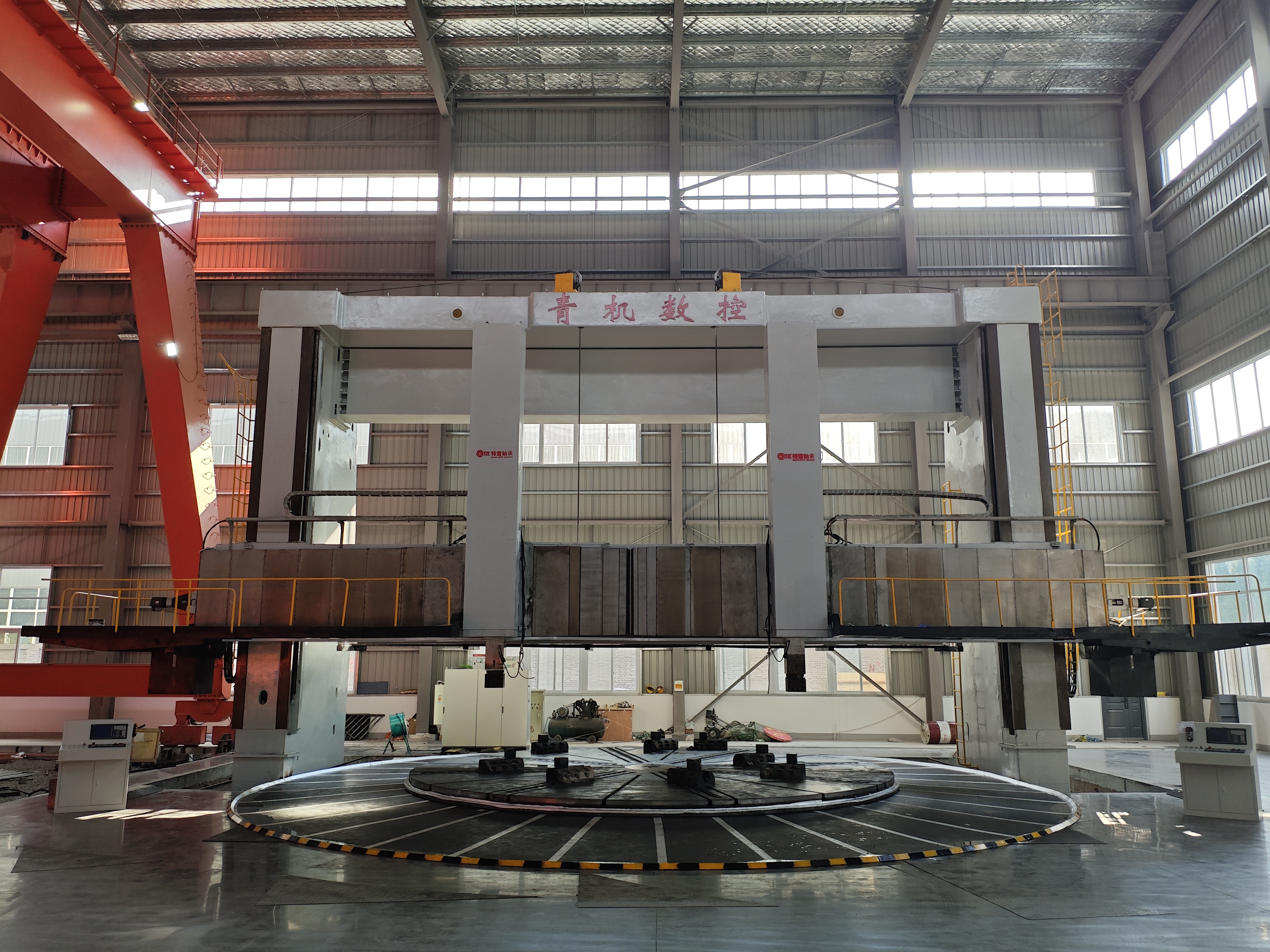

13-meter CNC vertical lathe

Handles large slewing bearings with superior accuracy, supporting high-load applications and consistent product quality.

Bearing processing technology

Slewing bearing seal

High-quality sealing protects slewing bearings from dust and moisture, ensuring stable rotation and long service life.

Bearing colorimetric testing

Accurate colorimetric testing ensures surface uniformity and high-quality finish of slewing bearings for reliable performance.

Slewing bearing heat treatment

Advanced heat treatment improves the hardness, strength, and durability of slewing bearings under heavy load conditions.

Custom bearing samples

Heavy-duty slewing bearings

High load-bearing slewing bearing for small and medium cranes.

External gear slewing bearing

Compact slewing ring bearing for excavators with stable rotation.

Precision slewing bearings

Precision slewing bearing for medical and aerospace equipment.

Future technology directions