Medical & Precision Equipment

- Home

- Applications

- Medical & Precision Equipment

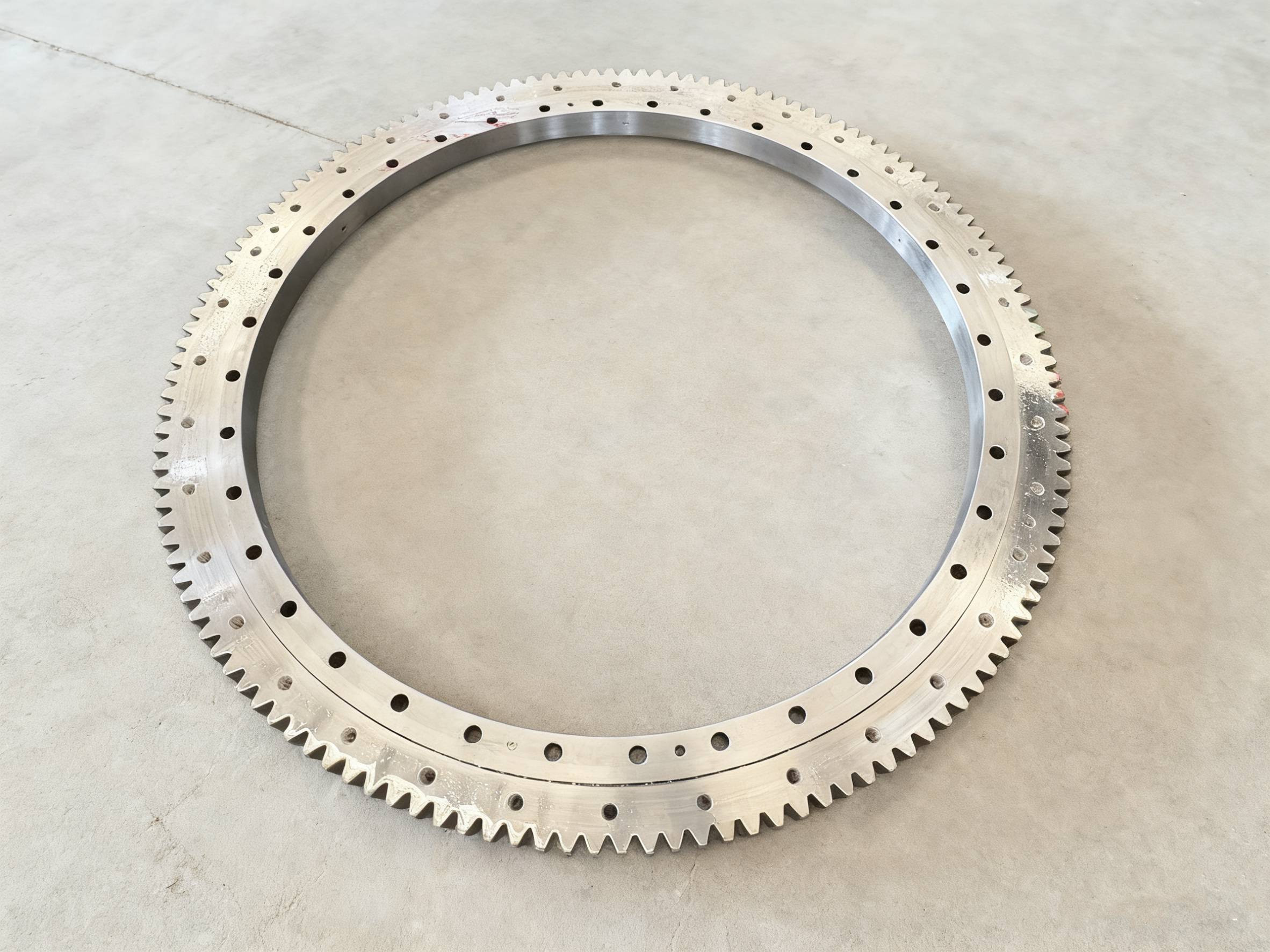

The Importance of slewing Bearings, the "Precision Core" of Medical Equipment

In modern medical and precision instrumentation, high precision and reliability are paramount design criteria. From diagnostic imaging to surgical robots, from laboratory analyzers to radiotherapy platforms, every rotational movement and every positioning operation relies on a stable and reliable bearing system. Bearings are not merely mechanical support elements; they are also critical components that influence the precision, safety, and lifespan of medical equipment.

In medical applications, bearings must meet the following requirements:

Ultra-high rotational accuracy

Low noise and vibration operation

Pollution-free and long-term operation

Corrosion resistance and easy cleaning properties

Special materials: 316L stainless steel, medical titanium alloy, ceramics and other materials with high compatibility

This requires the use of high-precision slewing bearings for medical equipment to ensure stable operation and enable accurate medical diagnoses for doctors and users.

Ⅰ. Typical Applications of Bearings in Medical and Precision Equipment

1. Imaging Systems

In CT, MRI, X-ray, and ultrasound equipment, rotating platforms or gantry must achieve high-speed, smooth, and extremely low-noise rotation. LTZC precision slewing bearings utilize ultra-precision ground raceways and a low-friction lubrication system, ensuring vibration-free scanning and clear, stable images.

CT Scanner Rotating Frames

MRI Turntables

Medical Scanning Platforms

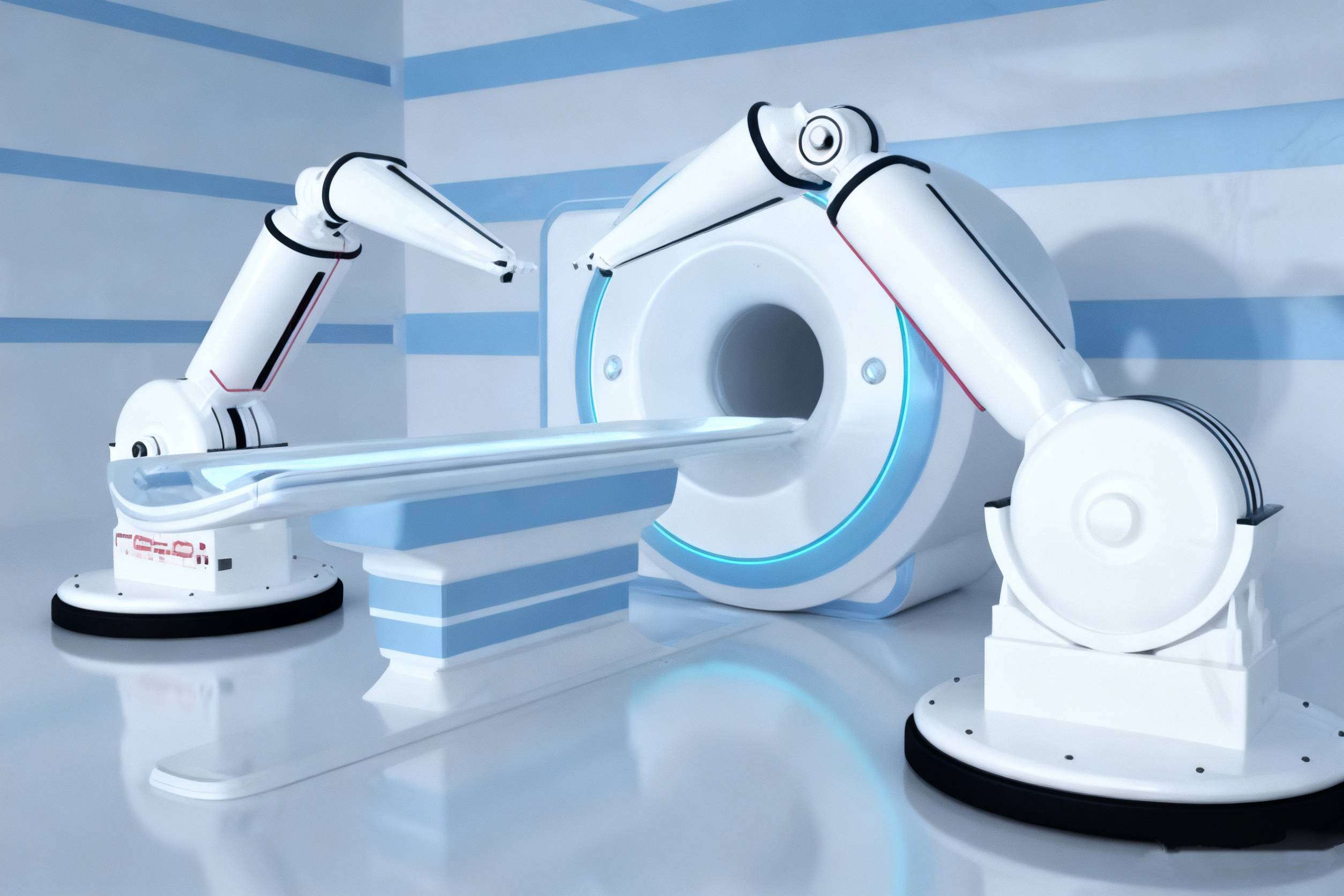

2. Surgical Robots & Navigation Systems

Medical robots require high repeatability and smooth motion control within a compact footprint.LTZC Cross Roller Slewing Bearings offer zero clearance, high rigidity, and micron-level angular adjustment, supporting doctors in high-risk minimally invasive procedures.

Surgical Robotic Arms

Medical Positioning Brackets

Minimally Invasive Surgery Navigation Platforms

3. Laboratory & Diagnostic Instruments

Bearings in analyzers, centrifuges, and sample processors must run at high speeds in clean conditions. LTZC medical-grade precision bearings made of 440C or 316L stainless steel ensure corrosion resistance and long-term accuracy.

Automated Analysis Systems

Testing Rotating Platforms

Precision Transmission Units

4. Rehabilitation & Imaging Support Systems

LTZC slewing bearings offer thin, lightweight, and silent structures suitable for medical beds, rehabilitation robots, and surgical tables.

Rehabilitation Robot Joints

Surgical Table and Hospital Bed Rotation Systems

Medical Positioning Bases

Ⅱ. Key Performance Requirements for Medical Bearings

| Performance Requirements | Technical Specifications | LTZC Solutions |

|---|---|---|

| High Rotational Precision | Micron-level runout, repeat error < 0.01° | Precision ground raceway + preload structure |

| Low Noise & Vibration | Avoid operational noise interference | Special grease + ultra-smooth surface |

| Clean & Corrosion Resistant | Complies with dust-free, rust-proof standards | Stainless steel + sealed protection design |

| Long Life & Maintenance-Free | Reduce downtime in hospital equipment | Sealed lubrication + self-lubrication channel |

| Lightweight & Compact | Meet compact equipment design needs | Thin-section bearing, crossed roller bearing |

Ⅲ. Technical Advantages of LTZC Medical Precision Bearings

High-Precision Manufacturing and Testing:CNC grinding and advanced inspection ensure international medical-grade accuracy.

Clean Process and Sealed Design:Food-grade grease and labyrinth seals meet medical safety standards.

Strict Material Selection:Stainless steel and corrosion-resistant alloys ensure durability in medical environments.

Customizable Solutions: Tailored design based on structural and load requirements, from prototype to mass production.

Ⅳ. Future Trends in Medical Device Bearings

Lightweight and high rigidity structures

Integrated smart monitoring and sensing systems

Low-friction materials and new ceramic rolling elements

AI-based predictive maintenance and data-driven control

LTZC is actively developing intelligent medical bearing systems for data-driven, monitorable, and predictive performance—enhancing the safety and reliability of next-generation medical equipment.

Ⅴ. Why Choose LTZC Medical Precision Bearings

✅ Over 20 years of experience in precision rotating components

✅ISO 13485 & ISO 9001 certified, meeting medical device standards

✅ OEM/ODM customization and mass production capability

✅ Full material-to-assembly traceability

✅ Global technical support and fast international service

Click here→ to view more information about LTZC bearings.