Construction & Heavy Machinery

- Home

- Applications

- Construction & Heavy Machinery

The Application of Slewing Bearings in Construction & Heavy Machinery

Slewing bearings play a critical role in construction and heavy machinery, enabling smooth 360° rotation, reliable load transmission, and high operational stability. As the core rotational component, slewing bearings support heavy loads and complex motion systems, ensuring that large-scale equipment operates safely, efficiently, and precisely under harsh working conditions.

What Is a Slewing Bearing?

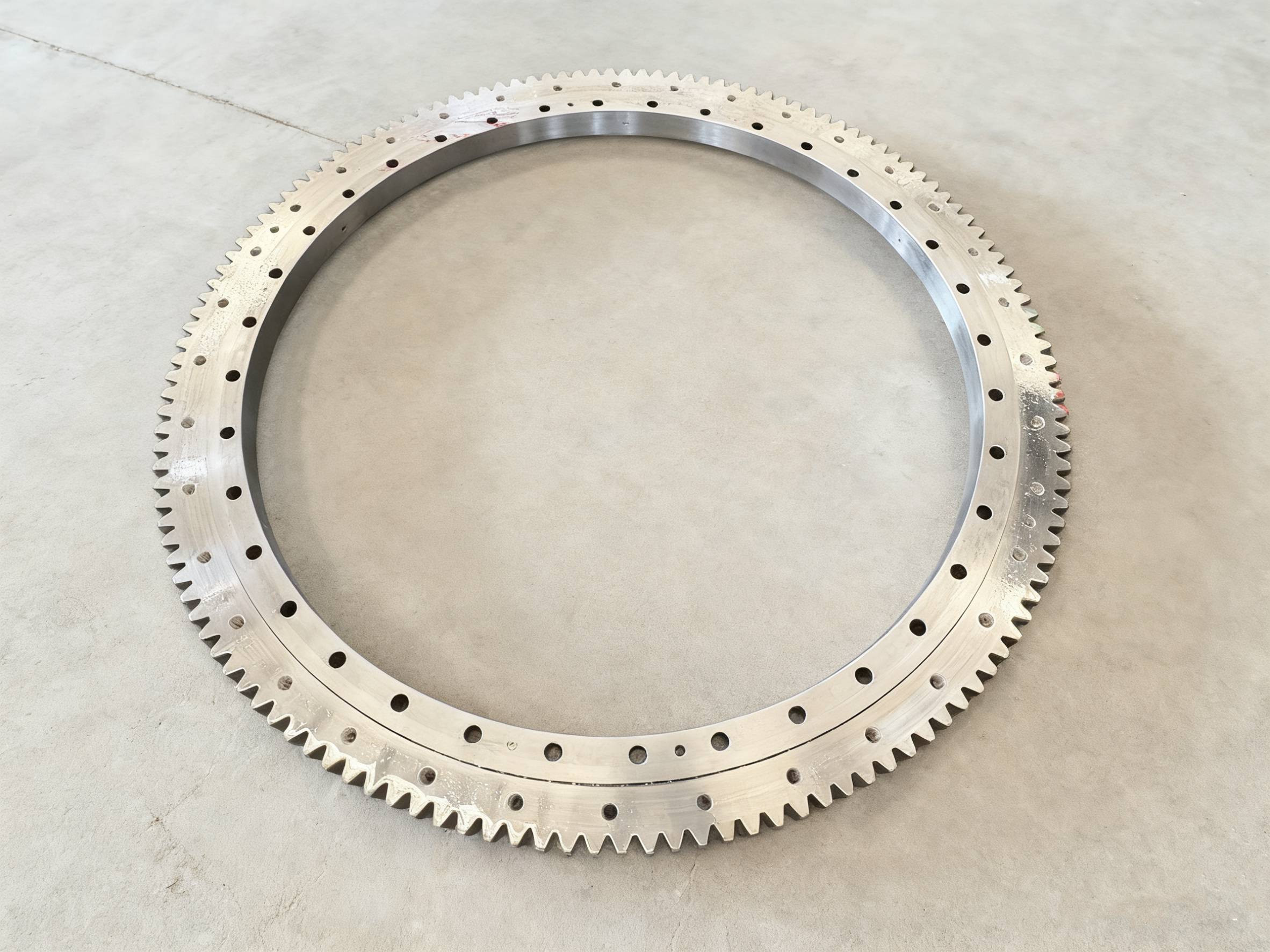

A slewing bearing (also known as a slewing ring or turntable bearing) is a specialized bearing designed to handle axial loads, radial loads, and overturning moments simultaneously. It combines structural strength with rotational flexibility, allowing heavy-duty machinery to rotate smoothly and safely.

Inner and outer rings – provide the main load-bearing structure.

Rolling elements – such as balls or rollers, enabling smooth rotation.

Spacers and cages – ensure even load distribution and precise alignment.

Seals and lubrication systems – protect against contamination and reduce wear for long service life.

Common Types of Slewing Bearings

Depending on application requirements and load capacity, the main slewing bearing types include:

Where Are Slewing Bearings Used?

In the construction and heavy equipment sector, slewing bearings are essential in various machines such as excavators, wheel loaders, bulldozers, cranes, piling machines, shield tunneling machines, and concrete equipment. These bearings enable critical rotational motion while bearing massive loads, ensuring smooth operation, safety, and long-term reliability.

Applications of Slewing Bearings in Key Equipment

1. Excavator Slewing Bearing

Excavator slewing bearings connect the upper structure and lower undercarriage, enabling the upper part to rotate 360 degrees. The inner ring typically meshes with the driving pinion connected to the lower chassis, while the outer ring is bolted to the upper body.

Low rotational resistance

High precision under heavy loads

Easy maintenance and installation

Single-row four-point contact ball slewing bearings – lightweight and compact, suitable for small and medium excavators.

Double-row ball slewing bearings – higher axial and overturning load capacity, suitable for medium to heavy excavators.

Three-row roller slewing bearings – extremely high load capacity, ideal for mining and large-scale excavators.

2. Crane Slewing Bearing

In cranes, the slewing bearing is the core component that enables the boom to rotate while supporting the weight of both the boom and the lifted loads. It must withstand axial, radial, and overturning loads caused by lifting and rotation, making reliability and precision essential.

Four-point contact ball bearings – for lighter or compact cranes.

Double-row ball bearings – balancing precision and high load.

Three-row roller bearings – for high-capacity lifting cranes.

A high-quality crane slewing bearing directly determines the machine’s operational stability, load capacity, and safety.

3. Wheel Loader Slewing Bearing

The slewing bearing in a wheel loader enables the bucket or front assembly to rotate precisely during heavy-duty operations. It must handle strong axial and radial loads, ensuring smooth performance even in challenging environments.

High load-bearing capacity

Excellent sealing and wear resistance

Compact structure for heavy-load applications

4. Piling & Concrete Machinery Slewing Bearings

Piling rigs and concrete machinery rely on slewing bearings to achieve precise positioning, smooth rotation, and stable operation under dynamic load conditions. They ensure high reliability during continuous, high-load operation and are often customized with reinforced raceways, high-strength materials, and enhanced sealing systems to resist harsh site conditions.

5. Shield Machine and Tunnel Boring Applications

In shield tunneling machines, slewing bearings must endure extreme loads, vibrations, and torque fluctuations. They provide the main rotation for the cutting head or shield structure, ensuring the tunneling system’s accuracy, stability, and safety. High-precision, large-diameter slewing bearings are used in this sector to ensure consistent performance under continuous operation.

Why Choose LTZC Slewing Bearings for Heavy Machinery?

LTZC specializes in the design, manufacturing, and customization of slewing bearings for construction and heavy machinery applications. With advanced production equipment, strict quality control, and precision machining capability, LTZC provides bearings that deliver:

High load capacity and long service life

Superior rotational precision and stability

Custom design options based on working conditions and installation requirements

Reliable performance in harsh environments

We supply a full range of slewing bearings for excavators, cranes, loaders, and piling machinery, ensuring your equipment runs with maximum efficiency and reliability.

Are you looking for slewing bearings for your next project?