Wind & Renewable Energy

- Home

- Applications

- Wind & Renewable Energy

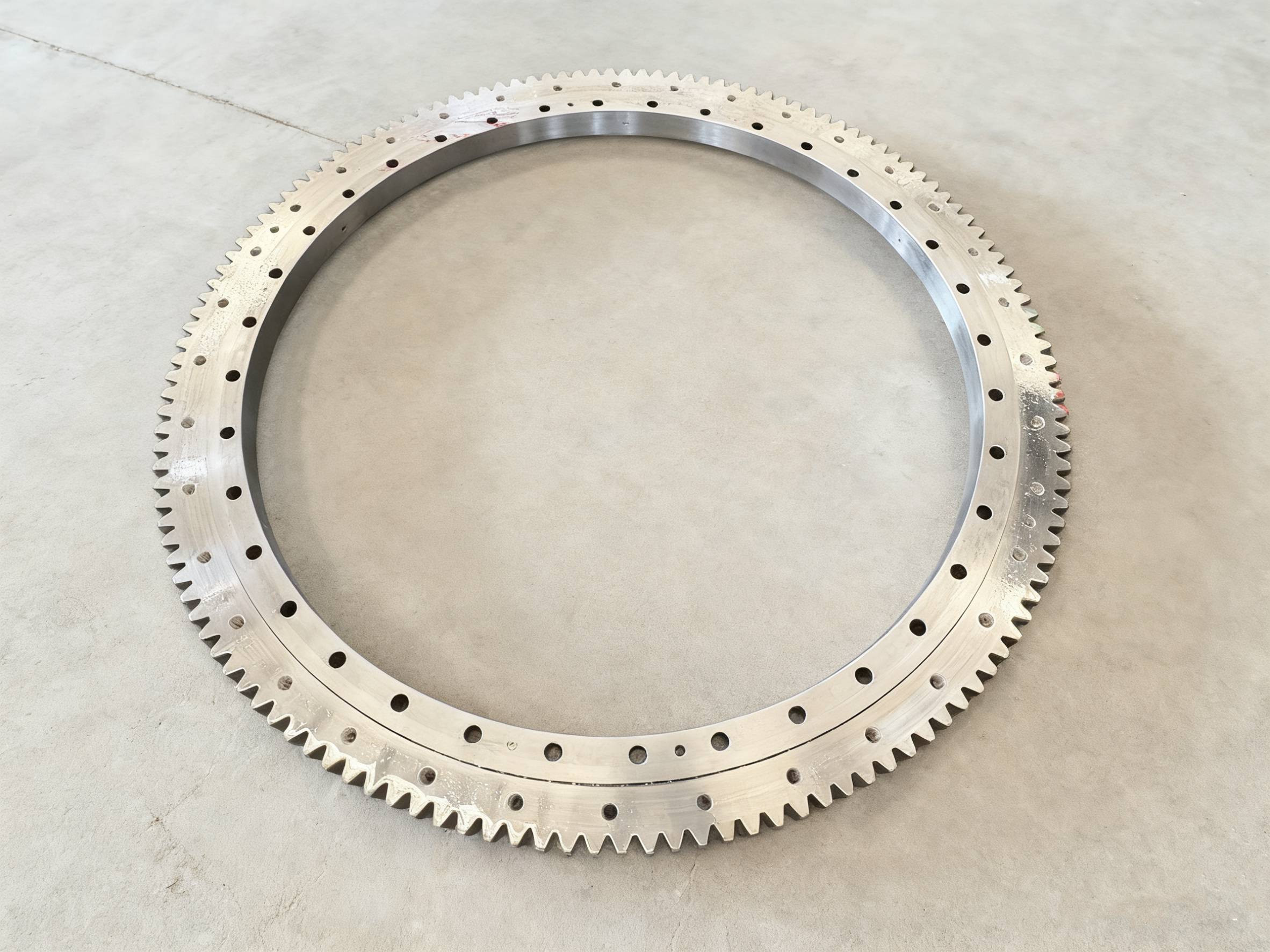

Renewable Energy - Wind Turbine Slewing Bearings

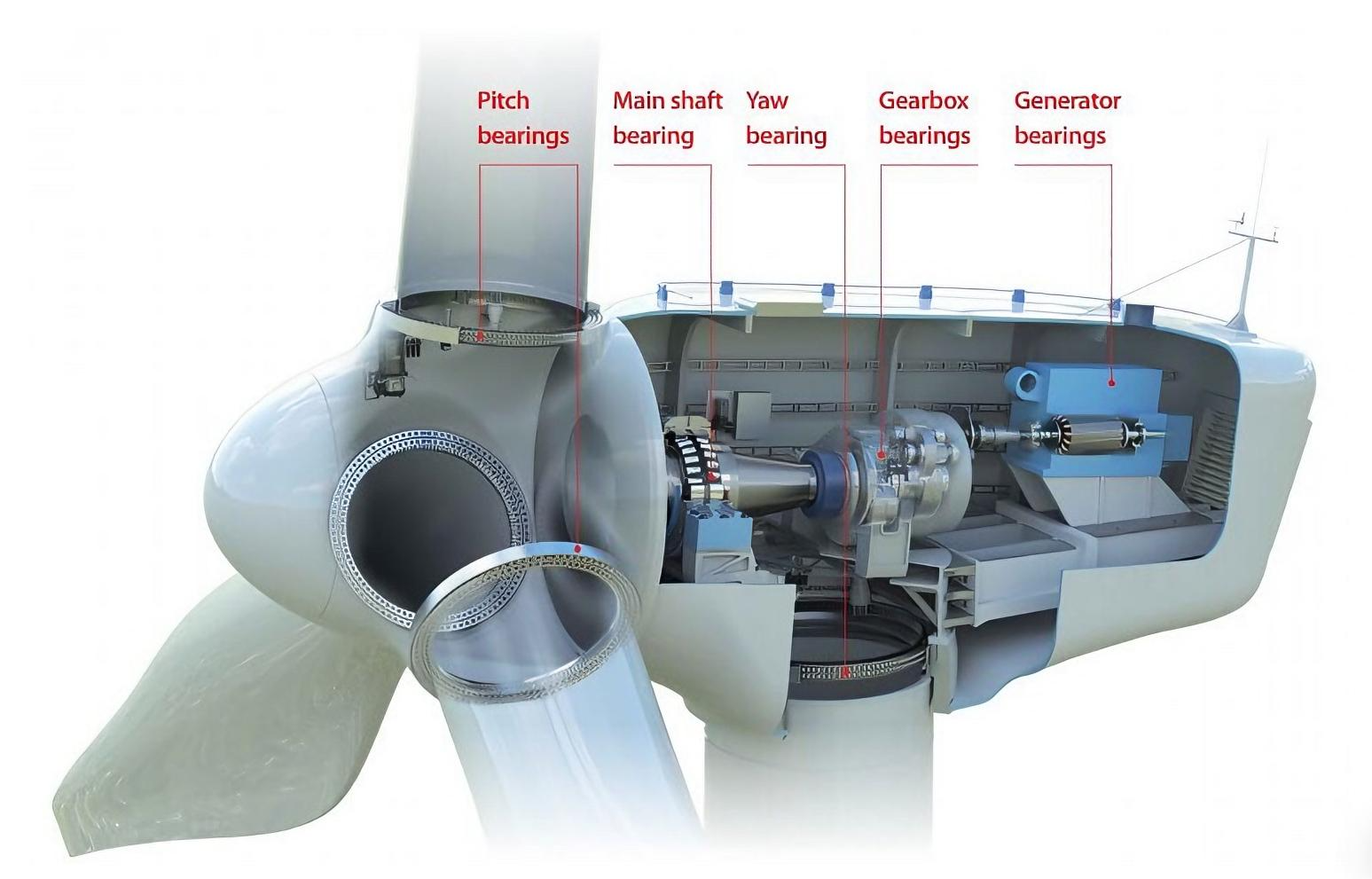

LTZC, a professional manufacturer of slewing bearings, offers bearings in various sizes suitable for heavy machinery such as excavators, cranes, and tunnel boring machines. In wind turbines, slewing bearings are used in two critical systems — the yaw system and the pitch system, each demanding exceptional reliability, accuracy, and durability.

1. Yaw System Slewing Bearing

The yaw system adjusts the turbine nacelle to face the wind direction. The slewing bearing supports the nacelle and upper components while enabling precise rotation to keep the blades at the optimal angle against the wind. This ensures maximum wind capture, higher power generation efficiency, and system stability even under rapidly changing wind conditions.

High static and dynamic load capacity

Smooth rotation under fluctuating torque

Long-term sealing and corrosion resistance

2. Pitch System Slewing Bearing

The pitch system controls the blade angle relative to the wind to optimize aerodynamic efficiency. Slewing bearings here must offer high precision and consistent torque control, allowing the blades to rotate smoothly and maintain turbine speed stability. Even in extreme weather — such as high winds, icing, or storms — the pitch bearing maintains balanced load distribution and operational safety, ensuring reliable energy output.

Types of Bearings Used in Wind Turbines

| Bearing Type | Structure & Characteristics | Suitable Turbine Size |

|---|---|---|

| Single-row four-point contact ball slewing bearing | Simple structure, light weight, supports axial/radial loads and tilting moment; available with internal, external, or no gear | Small wind turbines |

| Double-row ball slewing bearing | Dual raceways for higher load capacity; eight-point contact improves precision and rigidity | Medium-sized turbines |

| Three-row roller slewing bearing | Highest load-bearing capacity; separate rows handle radial and axial loads independently | Large and heavy-duty turbines |

How to Customize a Wind Turbine Slewing Bearing

The performance of a wind turbine depends heavily on selecting and designing the right bearing. LTZC provides full customization from concept to installation.

Define Technical Requirements – Determine bearing dimensions, load ratings, gear type, rotation precision, and expected service life according to the turbine’s specifications and environmental conditions.

Choose a Trusted Manufacturer – Partner with a professional slewing bearing manufacturer that complies with international standards and has proven experience in the wind energy sector.

Engineering Collaboration – LTZC’s engineering team conducts detailed analysis, offers design drawings, and provides tailored structural optimization for yaw and pitch systems.

Precision Manufacturing & Quality Testing – Bearings are produced under strict process control and undergo comprehensive inspection, including material testing, hardness checks, and rotational accuracy tests.

Delivery & Technical Support – LTZC provides installation guidance, maintenance training, and long-term after-sales service to ensure stable performance over the bearing’s entire lifespan.

Contact LTZC technical engineers for support.

Why Choose LTZC Wind Turbine Slewing Bearings

With over 20 years of expertise in bearing design and manufacturing, LTZC Bearing is one of China’s leading slewing bearing manufacturers for renewable energy applications. We have supplied over 10,000 sets of yaw and pitchslewing bearings to wind farms across 15+ countries, receiving high recognition for quality, precision, and reliability.

✅ Certified quality system compliant with international standards (ISO/CE)

✅ Custom-engineered solutions for onshore and offshore turbines

✅ High-strength materials and advanced heat treatment for longer service life

✅ Corrosion- and wear-resistant designs for extreme environments

✅ Comprehensive technical support and after-sales service

LTZC’s slewing bearings ensure accurate yaw and pitch control, minimal maintenance downtime, and enhanced turbine efficiency, helping global partners achieve sustainable and cost-effective energy production.

Quickly view LTZC ISO 9001, 14001, 45001, CCS, BV, ABS certificates→