Mining & Metallurgy

- Home

- Applications

- Mining & Metallurgy

Mining and metallurgy slewing bearings — facilitating efficient operation

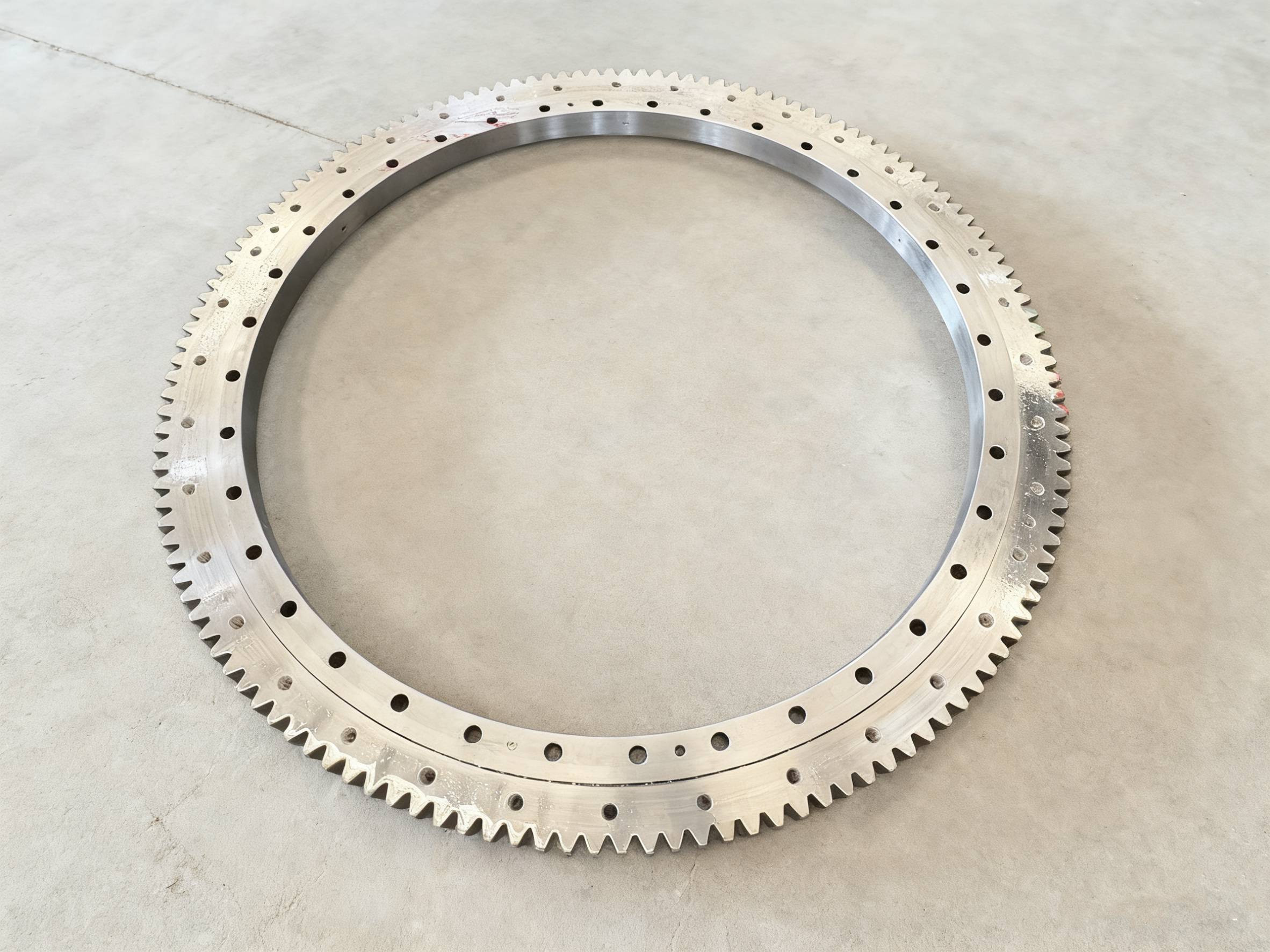

The mining and metallurgy industries represent some of the harshest operating environments in the world. Heavy-duty machines such as stacker reclaimers, excavators, crushers, and rolling mills must operate continuously under extreme dust, shock loads, vibration, and high temperatures. At the heart of these massive structures lies a crucial component — the slewing bearing. Responsible for enabling smooth rotation and supporting enormous combined loads, slewing bearings are fundamental to the efficiency, safety, and longevity of mining and metallurgical machinery.

I. The Harsh Reality of Mining Operations

Mining and metallurgical plants demand continuous operation in conditions that are both physically and mechanically severe. Dust, abrasive particles, water, and temperature variations constantly challenge bearing performance. In such scenarios, a standard industrial bearing simply cannot survive.

Key operational challenges include:

High static and dynamic loads: Machines handle tons of raw material with constant start-stop cycles. Bearings must withstand immense axial, radial, and overturning moments.

Severe contamination: Dust and metallic debris are pervasive, often penetrating conventional seals and accelerating wear.

Shock and vibration: Sudden impacts during crushing, drilling, or loading apply instantaneous forces beyond design tolerances.

Limited access for maintenance: Large machines cannot be easily stopped, making long-life bearings essential to minimize downtime.

In response, modern slewing bearings for mining integrate advanced sealing systems, surface hardening treatments, and optimized lubrication paths to ensure durability even in continuous heavy-duty service.

II. Core Functions of Slewing Bearings in Mining & Metallurgy

Slewing bearings provide rotational movement and structural support across a wide range of mining and metallurgical equipment. Their role is not merely mechanical — they are central to machine precision, load control, and energy efficiency.

2.1 Slew ring excavator and Shovels

Large mining excavators rely on slewing bearings to rotate the upper structure. The bearing carries the entire weight of the upper frame, boom, and load while enabling 360° rotation. Durability here depends on raceway hardness, gear precision, and lubrication integrity, ensuring stable operation during continuous digging cycles.

2.2 Stackers, Reclaimers, and Conveyors

In open-pit mines and bulk handling terminals, massive stacker-reclaimer systems depend on large-diameter slewing bearings (often over 4 m in diameter). These components enable smooth, precise rotational motion of the boom arms under extremely heavy and asymmetric loads. Four-point contact ball or cross roller slewing bearings are preferred for their combined load capacity and low friction torque.

2.3 Crushers, Screens, and Rotary Kilns

In metallurgical processing, slewing bearings are integrated into rotary kilns, crushing mills, and screening systems. Their ability to maintain concentric alignment under heat and continuous vibration directly impacts output stability and safety.

2.4 Material Handling Cranes and Loaders

Overhead cranes, casting manipulators, and loading bridges rely on slewing ring for smooth rotation and precise load positioning. With proper design and sealing, they deliver reliable service even in environments contaminated by metal dust and moisture.

Types of Slewing Bearings

| Slewing Bearing Type | Structural Features | Application Scenarios | Core Advantages | Typical Equipment Examples |

|---|---|---|---|---|

| Four-Point Contact Ball Bearing | Inner and outer raceways are arc-shaped; a single steel ball bears axial, radial loads and overturning moment simultaneously. | Stacker-reclaimers, excavators, material handling cranes — medium-load conditions requiring 360° continuous rotation and low friction torque. | Multi-directional load bearing, low friction torque, compact structure. | Large stacker-reclaimers (Ø > 4 m), general excavators. |

| Cross Roller Slewing Bearing | Rollers arranged in a 90° cross pattern; adjacent rollers in vertical contact, bearing multi-directional loads with extremely high rigidity. | Metallurgical rolling mill turntables, heavy excavator upper slewing structures — heavy-load, high-impact, high-precision scenarios. | Excellent rigidity, high rotation accuracy, strong impact resistance. | Large mining excavators (bucket capacity > 50 m³), metallurgical rolling mills. |

| Three-Row Roller Bearing | Contains three rows of rollers: separate rows handle radial and axial loads, offering superior load capacity. | Extra-heavy equipment such as large mining excavators, rotary kiln supports — coping with extreme static/dynamic loads and overturning moments. | Extremely high load-bearing capacity, outstanding overload resistance. | Extra-large mining excavators, metallurgical rotary kilns. |

| Double-row Different-diameter Ball Bearing | Uses two sizes of steel balls to balance load distribution and maintain a compact structure. | Port cranes, small-to-medium mining equipment slewing mechanisms — space-limited scenarios requiring multi-directional load bearing. | Good space adaptability, balanced multi-directional load bearing. | Small-to-medium port cranes, compact mining equipment. |

| With External Bearing/Internal Gear Bearing | Integrates gears on four-point contact, cross roller, or other structures to combine rotation and power transmission. | Upper slewing systems of excavators/loaders, metallurgical rotating platforms — scenarios requiring direct torque transmission. | Integrated transmission, reducing additional components. | Mining excavators, metallurgical rotating platforms. |

III. Engineering Requirements for Mining Bearings

Mining and metallurgical operations impose unique technical requirements that go beyond standard bearing specifications. The table below summarizes key performance factors and engineering requirements.

| Performance Factor | Engineering Requirement |

|---|---|

| Load capacity | Must sustain high axial, radial, and overturning loads with minimal deformation. |

| Sealing & protection | Multilayer sealing systems prevent dust and slurry intrusion. |

| Material hardness | Raceway surfaces typically reach 55–62 HRC for wear resistance. |

| Corrosion protection | Surface coatings or phosphating prevent degradation in wet environments. |

| Lubrication | Centralized or automatic lubrication ensures consistent grease film under heavy loads. |

| Alignment tolerance | Must accommodate minor structural misalignments due to uneven foundations. |

| Inspection & monitoring | Embedded sensors or smart monitoring allow predictive maintenance and reduced downtime. |

Such requirements demand both precise engineering and reliable material science. Manufacturers like LTZC focus on customized solutions—optimizing geometry, heat treatment, and sealing structures according to each working condition.

IV. Advantages of LTZC Mining Slewing Bearings

Reduced Maintenance Frequency – Longer service intervals thanks to optimized lubrication and advanced sealing.

Enhanced Safety – Consistent rotation minimizes the risk of misalignment or mechanical seizure.

Higher Efficiency – Smooth operation under high torque reduces energy consumption and noise.

Longer Equipment Life – Stable support minimizes structural stress and fatigue cracking.

V. How to Maintain Mining Slewing Bearings

Proper care is the backbone of slewing bearing longevity in mining environments. Best practices include:

Scheduled lubrication: Use high-viscosity grease with solid additives suitable for dusty, wet, and high-load conditions.

Seal inspection: Replace seals during each major overhaul to prevent contaminant ingress.

Torque monitoring: Regularly check bolt torque and structural alignment to avoid uneven stress.

Condition monitoring: Use vibration and temperature sensors to identify early-stage bearing wear.

Periodic re-lubrication: Implement automatic systems to ensure consistent lubrication during continuous operation.

View LTZC bearing Installation and maintenance guide

VI. Why Choose LTZC Slewing Bearings for Mining & Metallurgy

Heavy-Duty Structural Design: LTZC's mining and metallurgical slewing bearings are designed for high-impact and continuous operation environments. They withstand significant radial and axial loads, ensuring smooth rotation even under unbalanced loads.

Superior Sealing and Protection Systems: High-strength rubber and anti-corrosion coatings prevent dust and moisture intrusion, ensuring low friction and low noise levels during long-term operation.

Precision Manufacturing and Quality Control: LTZC utilizes internationally standardized production systems, with final products certified by ISO/CE/SGS. Each bearing has a unique product number.

Customized Engineering Solutions:We support tooth hardening and special coatings. We also provide OEM customers with installation guidance and ongoing technical support.

Service and Partnership Advantages: LTZC offers full lifecycle technical support (design, installation, maintenance, and upgrades). Engineering inspection reports, material certificates, and factory data packages are available upon request.

For tailored mining slewing bearing solutions, contact LTZC's engineering team for application-specific design, installation guidance, and long-term support.

Quickly view LTZC ISO 9001, 14001, 45001, CCS, BV, ABS certificates→