Resources

- Home

- Resources

Bearing Support Center

Bearing Material

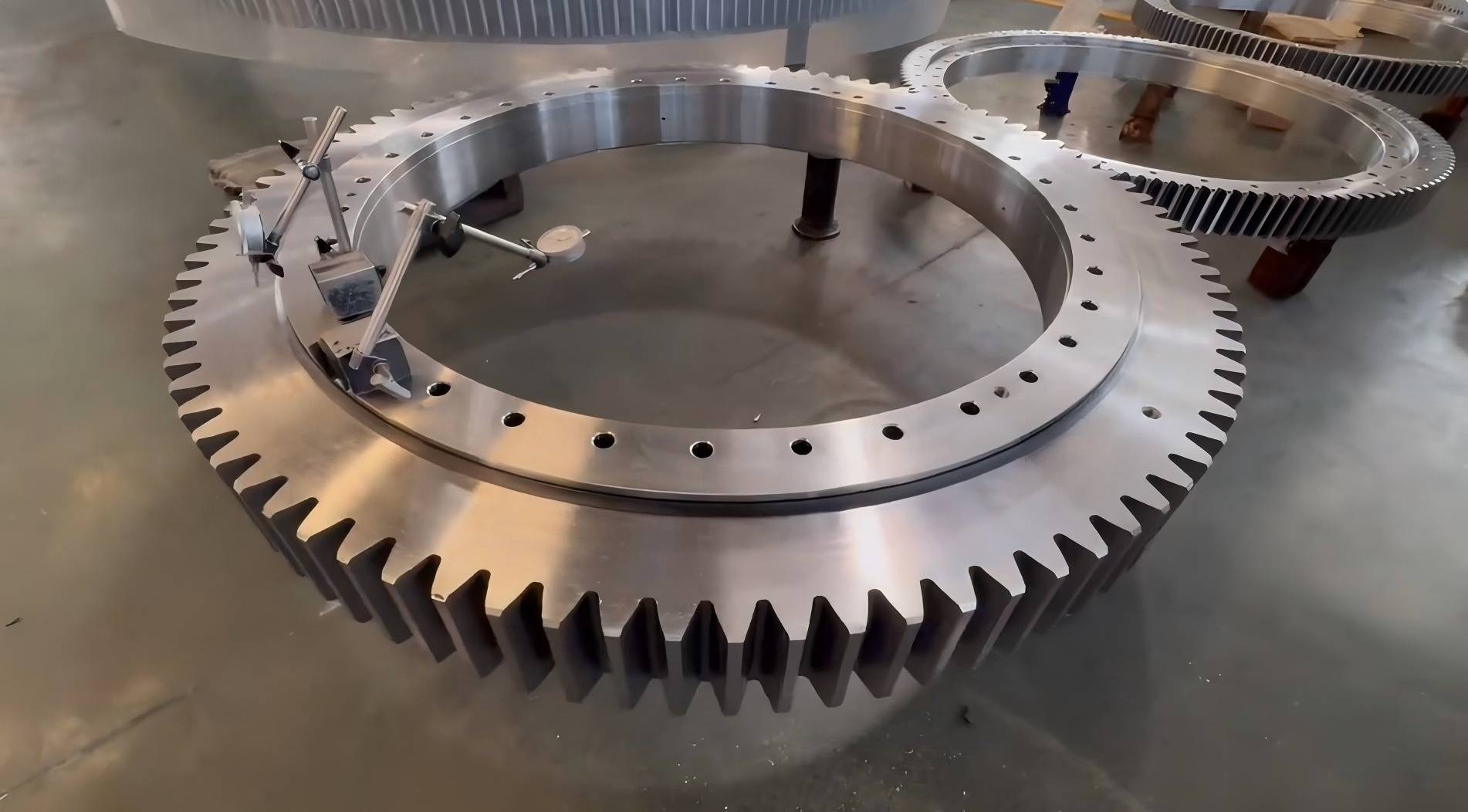

LTZC selects a variety of high-performance slewing bearing materials, such as 45 Steel, GCr15/GCr15SiMn, and 40Cr Steel

Bearing Seal

LTZC bearings offers a variety of specialized sealing structures and materials for slewing bearings and large custom bearings.

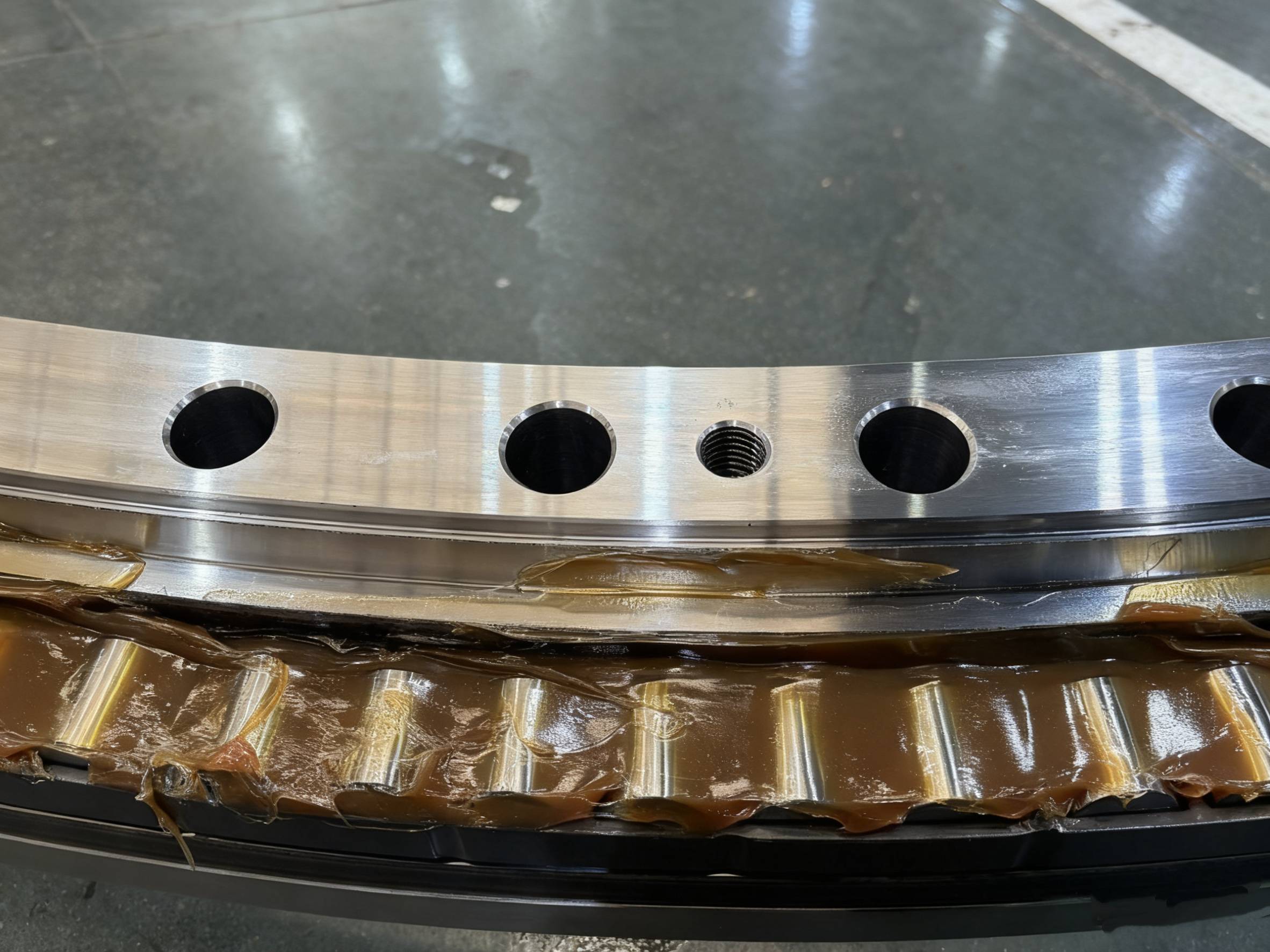

Bearing Lubrication

LTZC provides customers with professional lubrication solutions for slewing bearings, which can effectively reduce friction and raceway wear.

Bearing installation and maintenance

Proper installation and maintenance of slewing bearings are crucial for extending service life and maintaining efficient equipment operation. Improper installation or lack of maintenance often leads to premature wear, reduced load-bearing capacity, equipment downtime, and even safety hazards. LTZC, with over 20 years of bearing R&D experience, is a leading slewing bearing manufacturer in China. With a professional engineering team, comprehensive technical support, and standardized installation procedures, LTZC ensures even stress distribution and high-precision operation, providing a safer and more reliable guarantee for the long-term stable operation of equipment.

Get a quoteHow to select a suitable slewing bearing?

| Selection Factor | Description | Selection Criteria |

|---|---|---|

| Load Type | Axial, Radial, Tilting Moment | Heavy load: Three-row roller bearing, Cylindrical ball bearing & roller combination bearing Medium load: Four-point contact ball bearing, Double-row roller bearing High precision: Crossed roller bearing, Thin-section bearing |

| Load Capacity | Magnitude and direction of load | Based on maximum working load + safety factor (1.2–1.5) |

| Structure Type | Four-point ball, Double-row ball, Three-row roller, Crossed roller, Cylindrical ball & roller combination | Choose based on load, precision, available space, and cost |

| Installation Dimensions | Outer diameter, Inner diameter, Mounting holes, Pitch circle diameter | Match according to equipment interface design |

| Gear Ring Requirement | External teeth, Internal teeth, Toothless | Depends on transmission method (gear/motor) |

| Working Environment | High temperature, Low temperature, Dust, Corrosion, Heavy load | Select appropriate sealing, corrosion protection, and lubricant |

| Rotational Accuracy | Backlash, rotational smoothness, rigidity | High precision structures required for automation/robotics |

| Material & Hardness | 50Mn, 42CrMo, Quenching hardness | High load or long-life applications prefer 42CrMo |

| Speed & Frequency | Rotational speed, Start/stop frequency | High frequency: Crossed roller bearing / Low speed heavy load: Three-row roller bearing |

| Manufacturer Capability | Manufacturing precision, Inspection equipment, Technical service | Choose manufacturers with installation & maintenance capability, e.g., LTZC provides professional on-site installation guidance and maintenance recommendations |

Contact LTZC engineers for quick bearing selection advice≤

Download Center

![]() Bearing Installation & Maintenance Instructions

Bearing Installation & Maintenance Instructions