Quality & Certifications

- Home

- Company

- Quality & Certifications

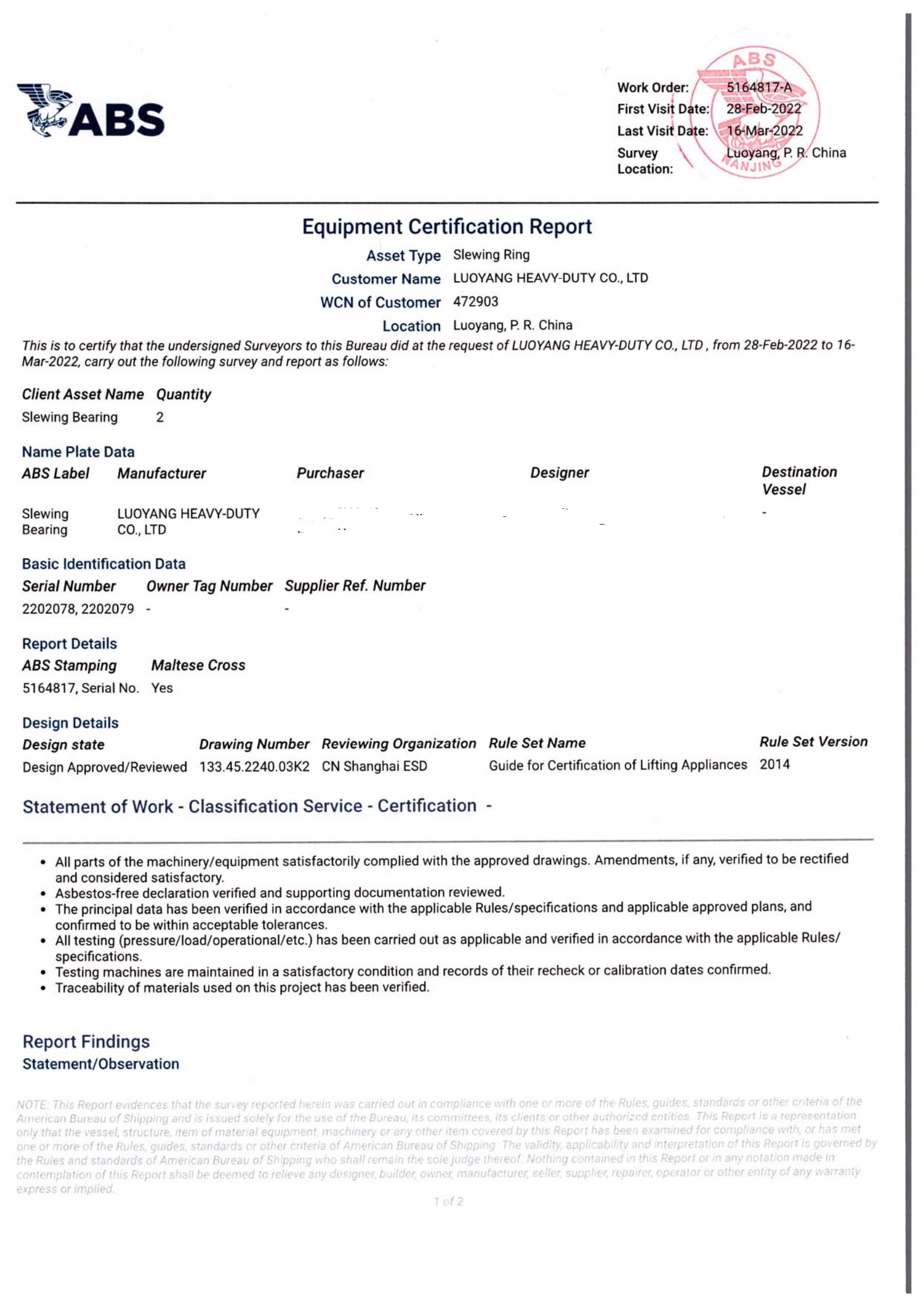

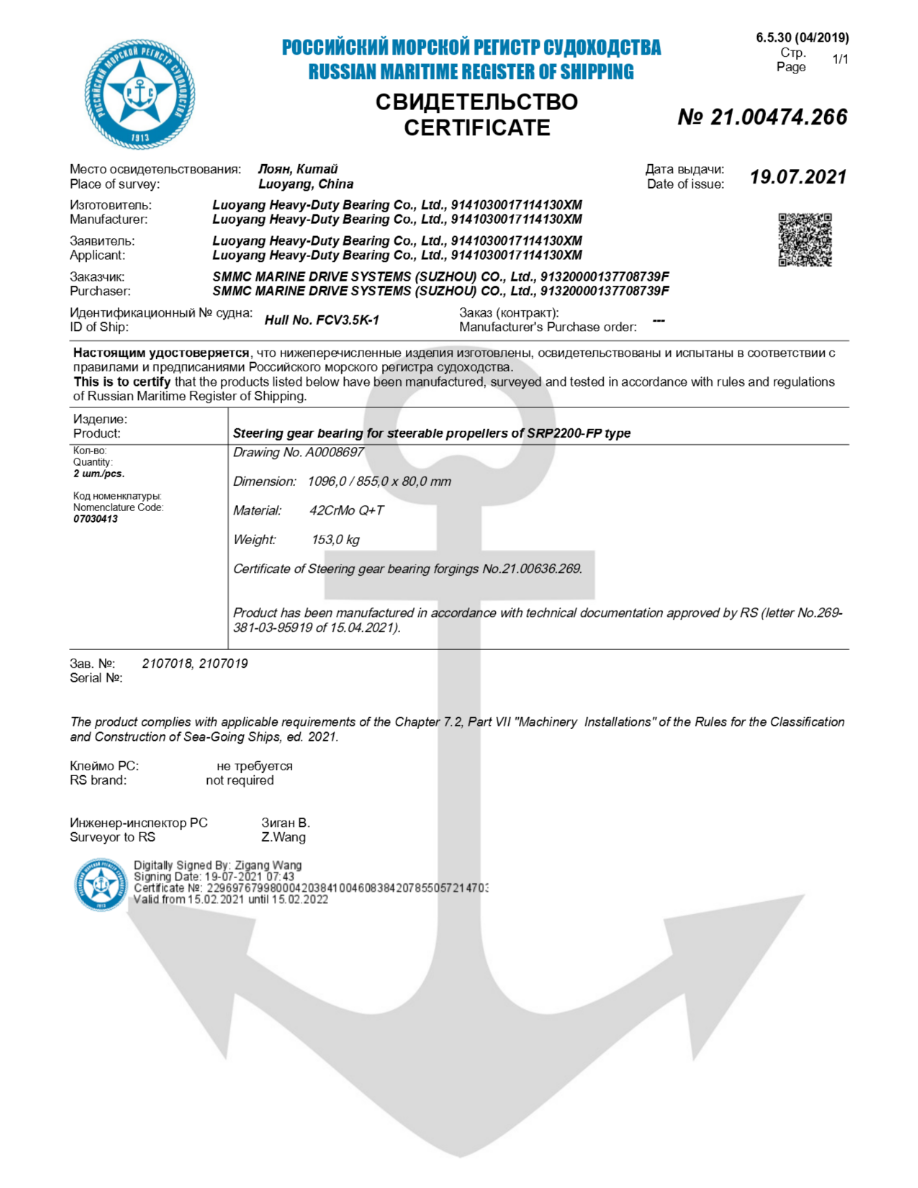

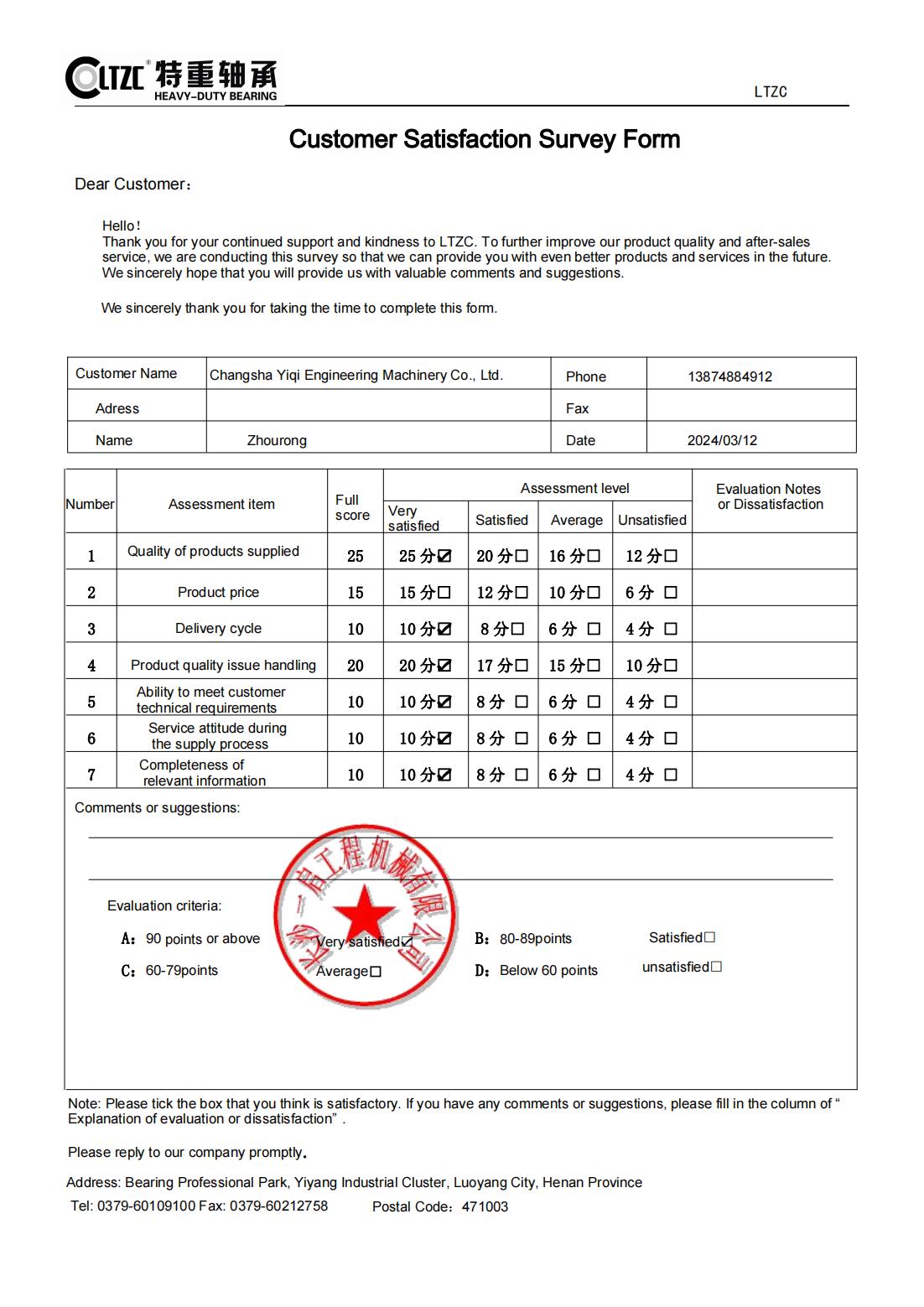

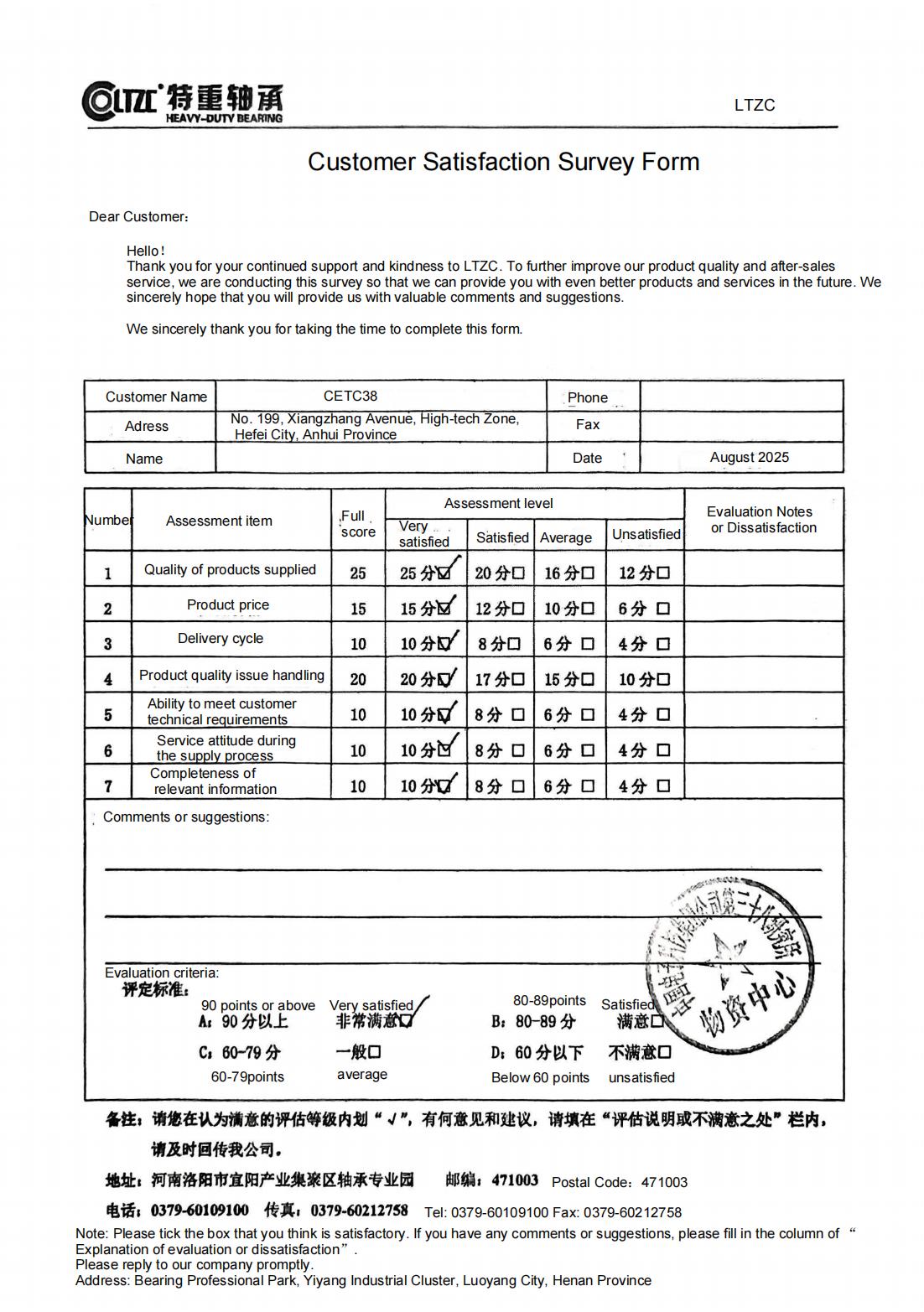

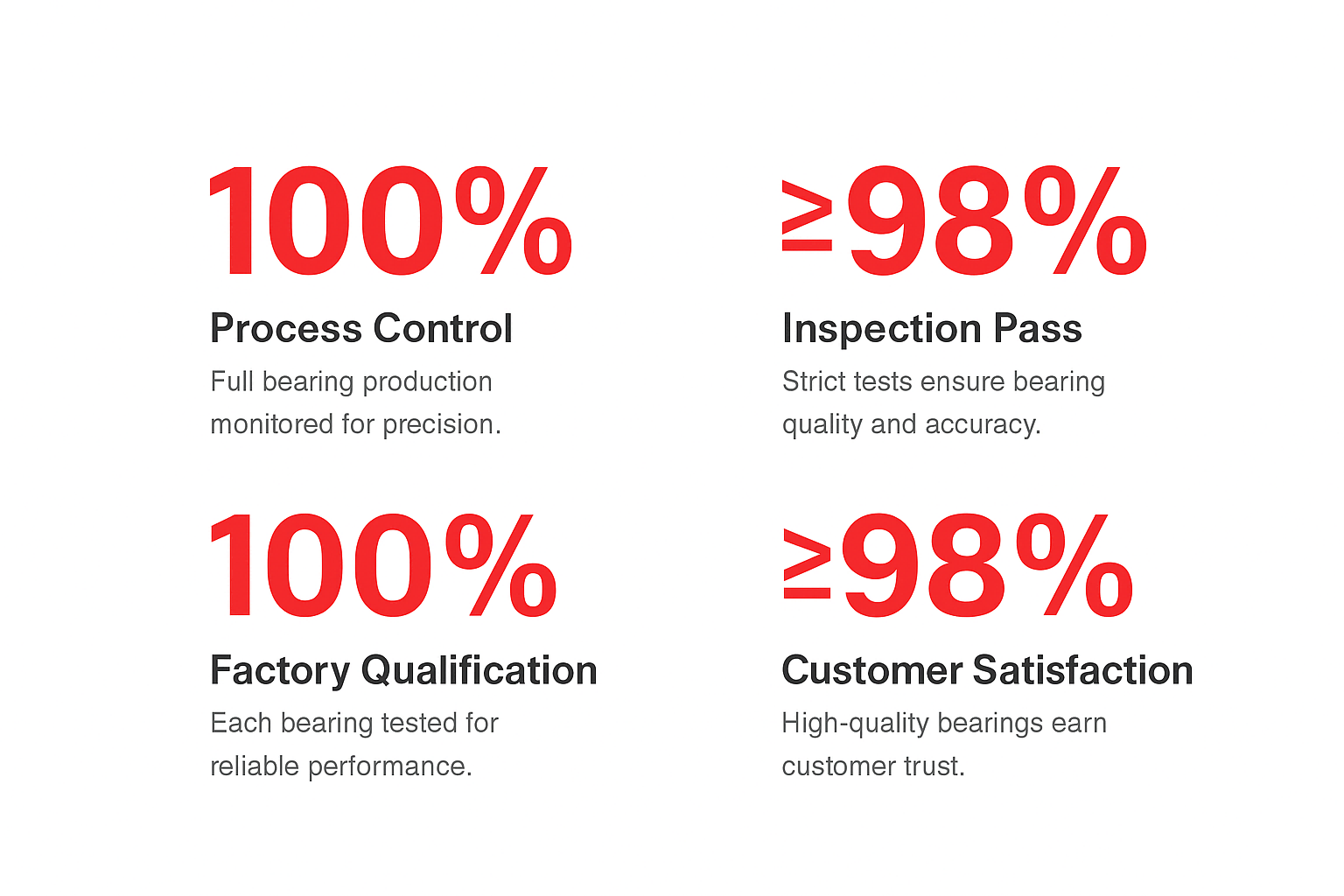

At LTZC, our quality goals are driven by precision, consistency, and innovation. As a leading slewing bearing manufacturer, we are committed to providing slewing bearings that meet global industry standards. Our rigorous quality management system ensures durability, smooth operation, and reliability in demanding applications such as construction machinery, wind turbines, mining, and industrial automation. Through continuous improvement in manufacturing technology and precision control, LTZC strives to be your most trusted bearing supplier—providing customized bearing solutions with superior quality and performance.

Get a quote

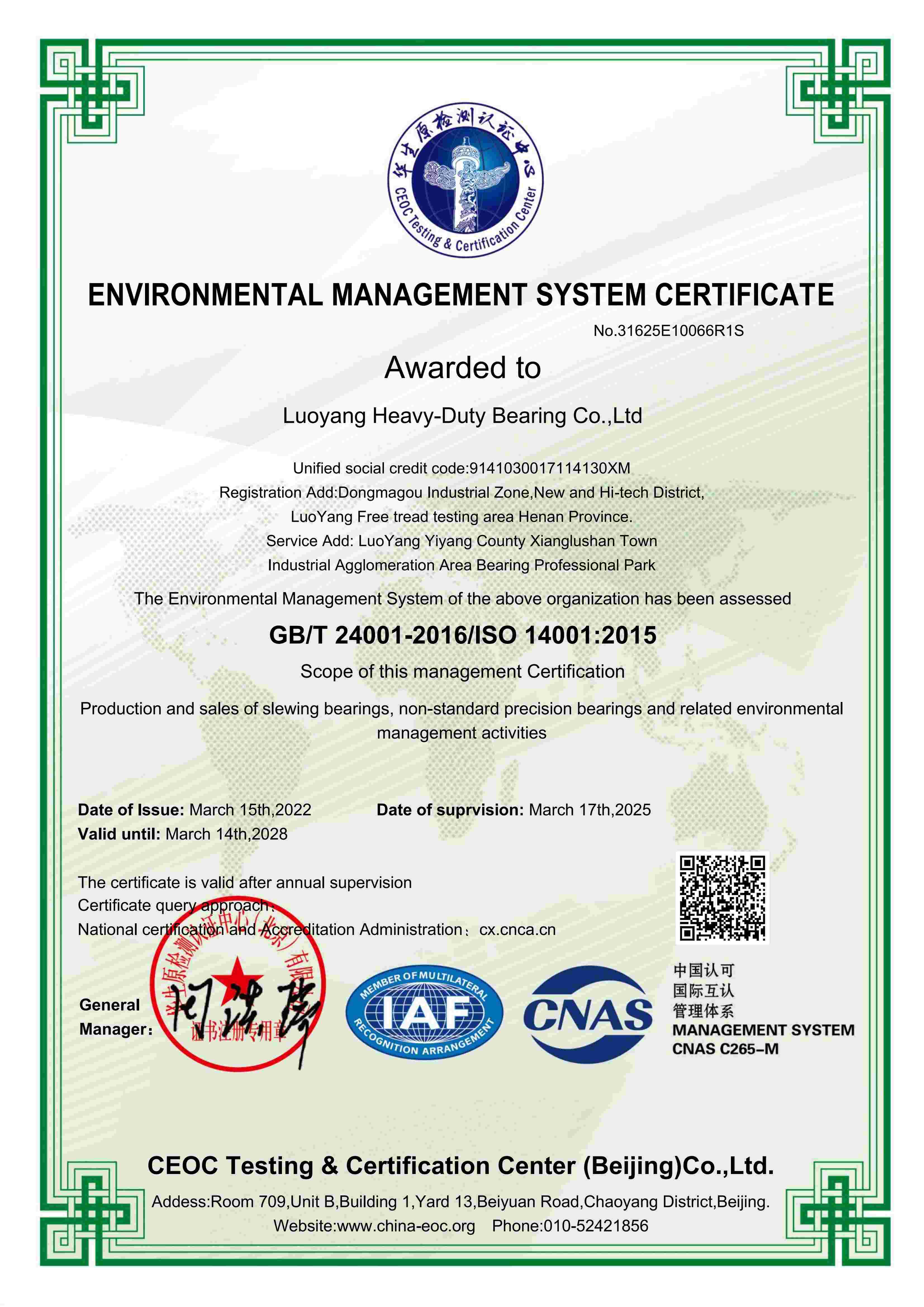

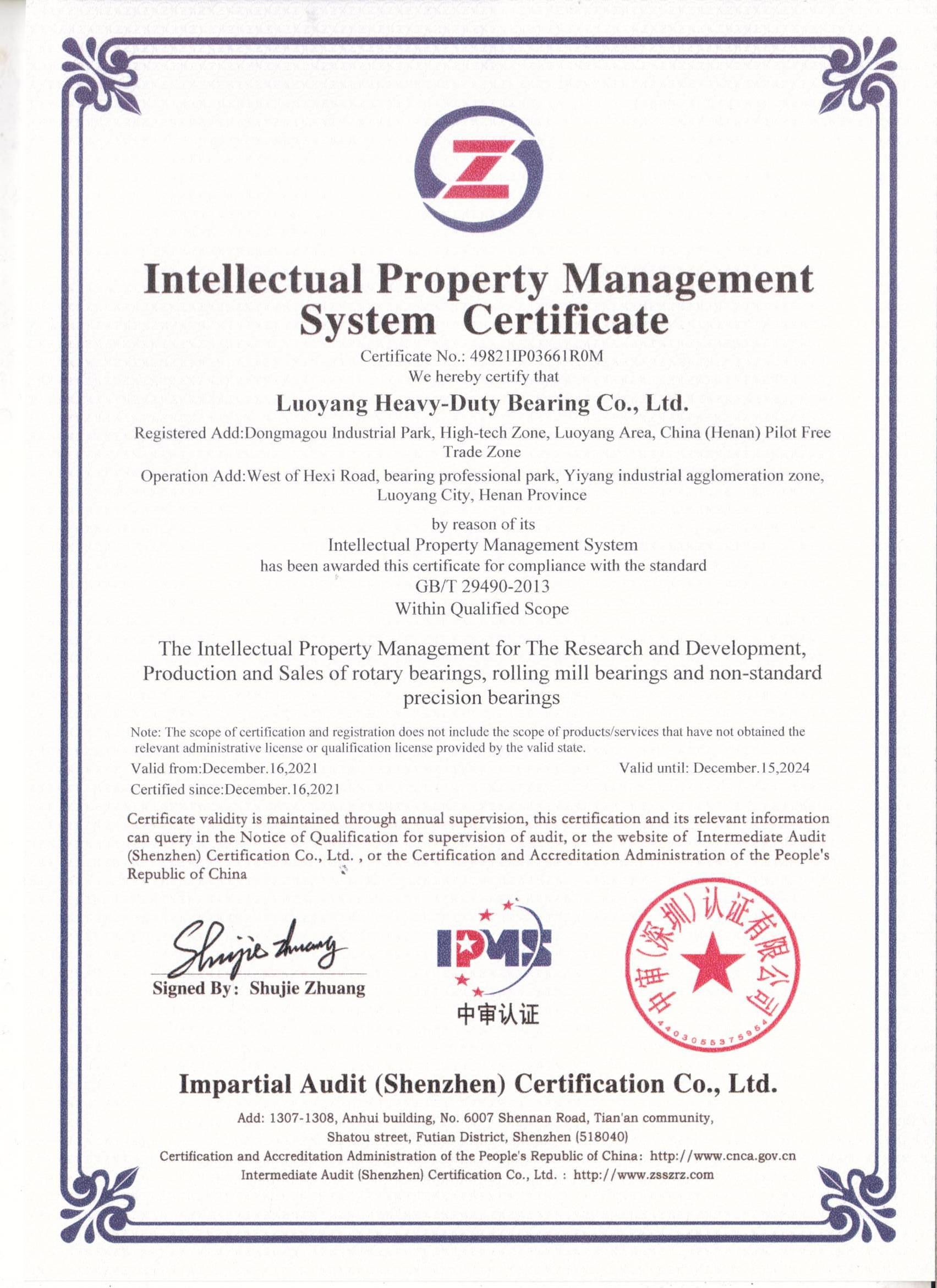

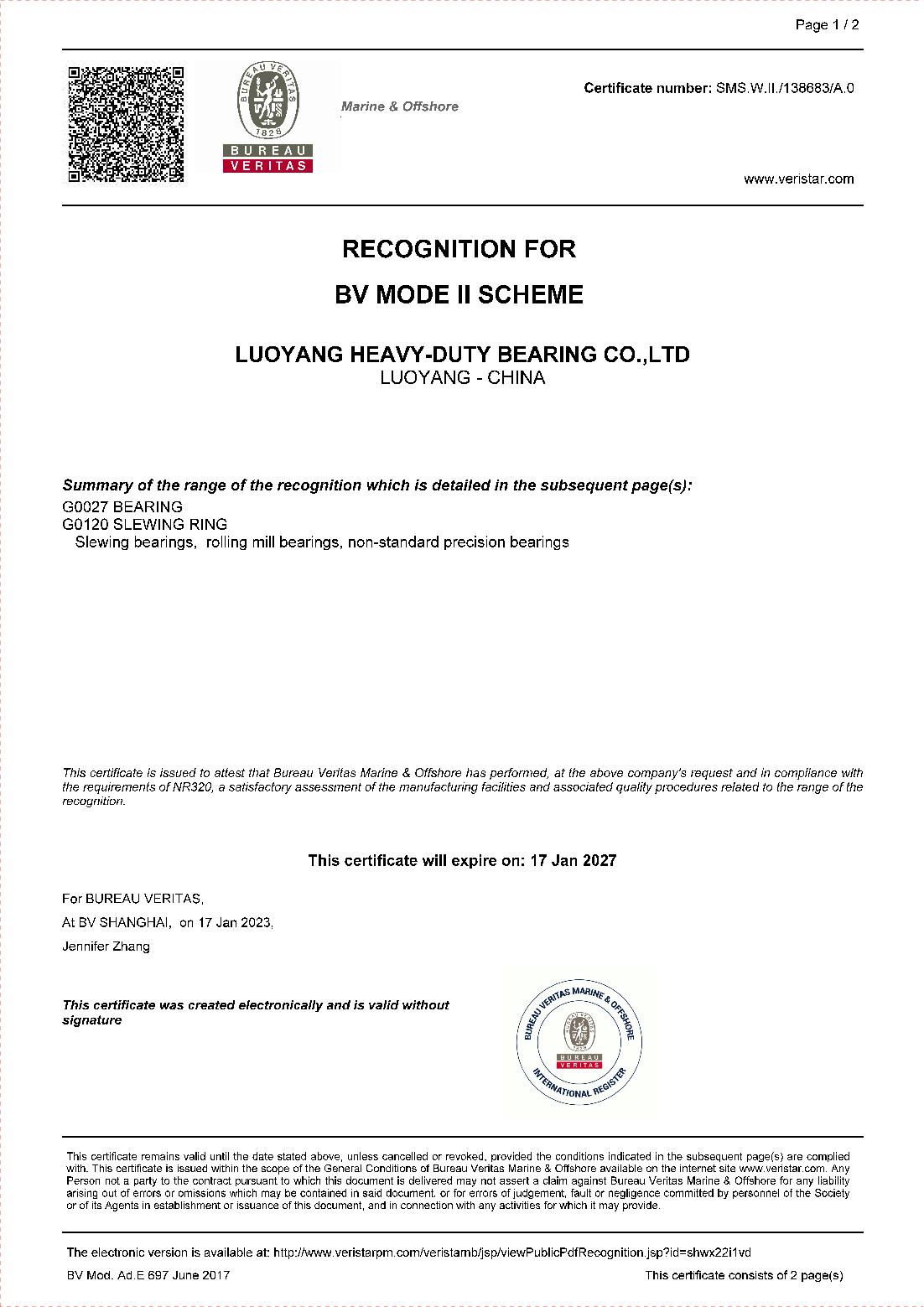

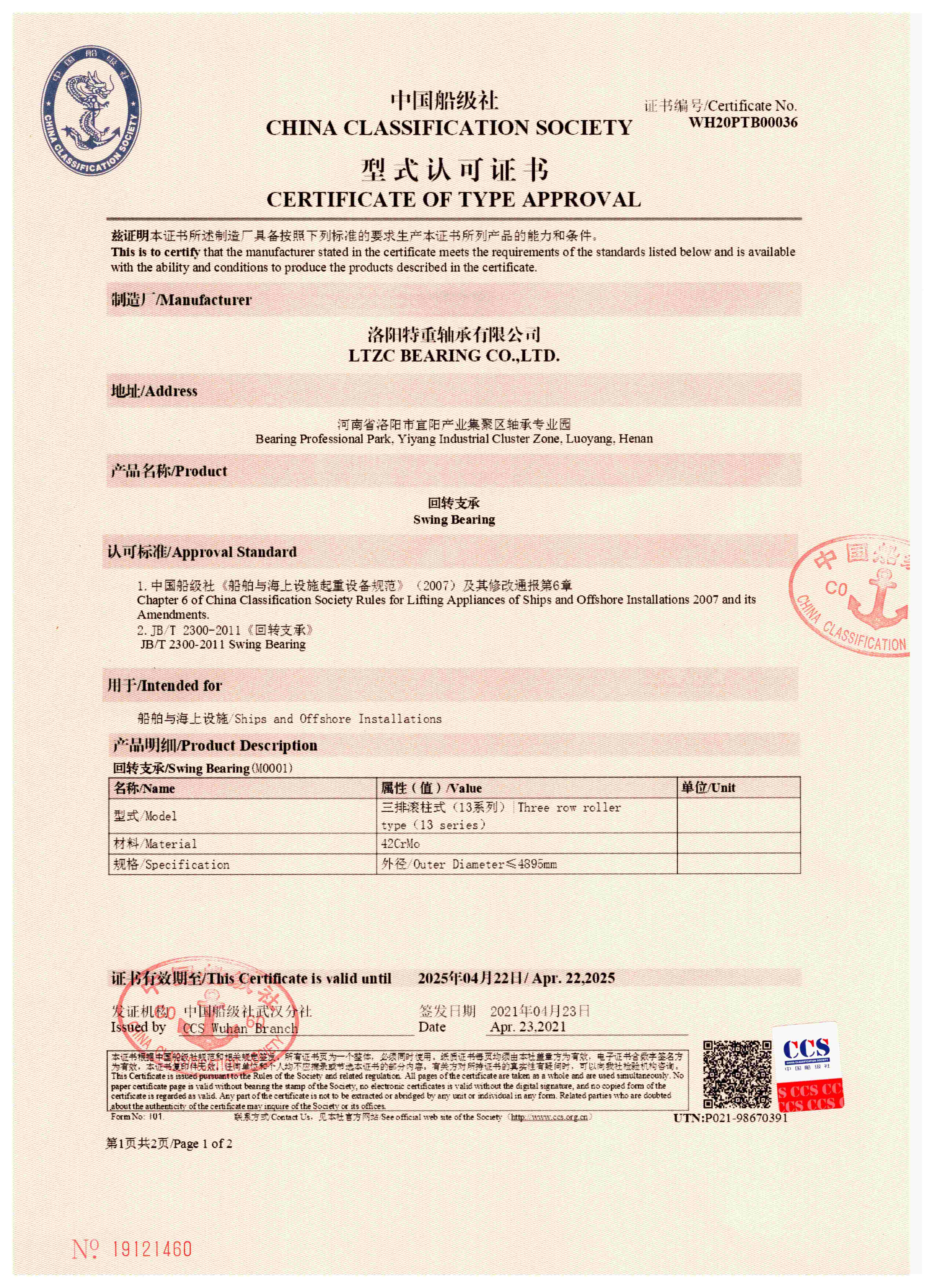

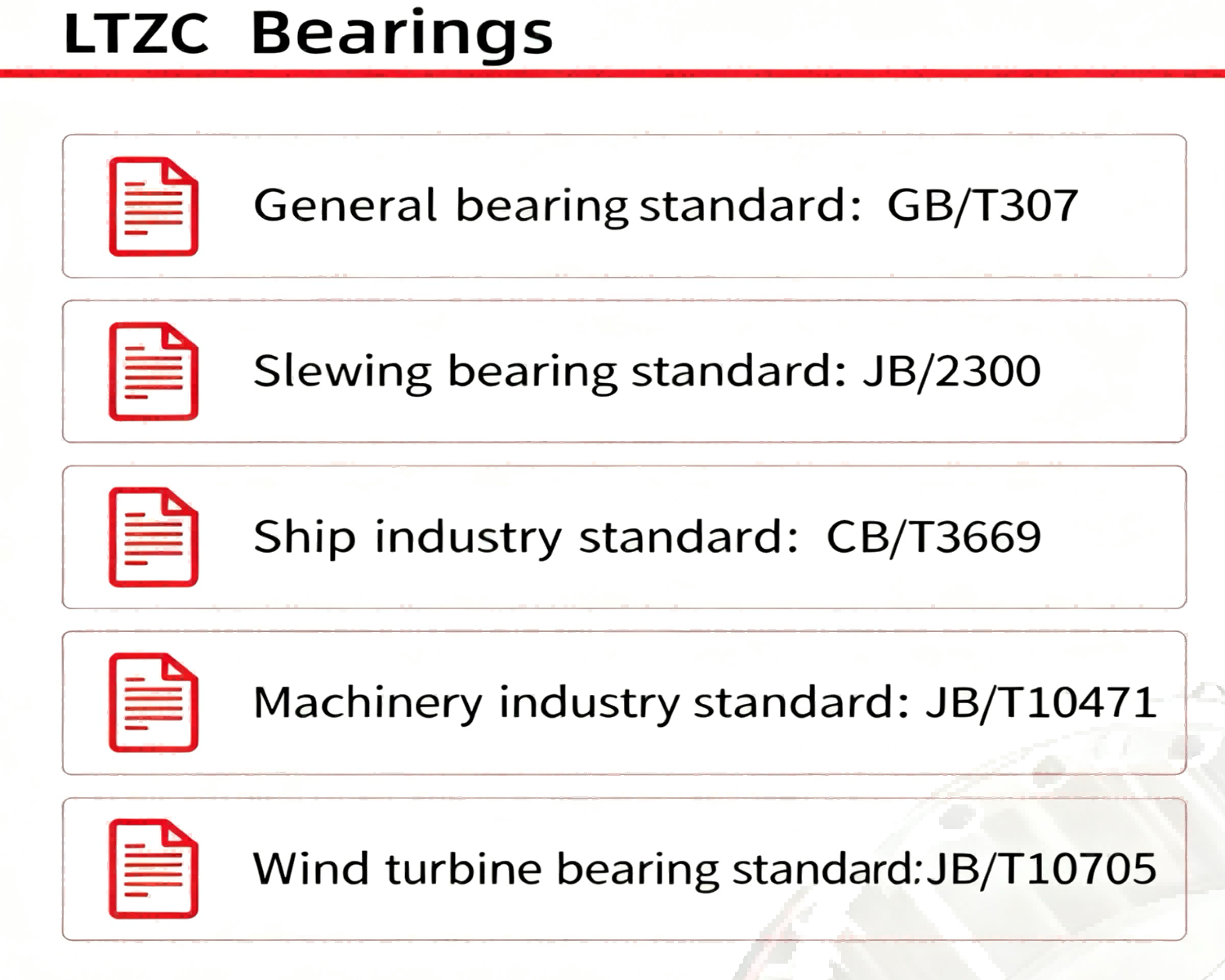

LTZC bearings strictly adhere to international quality standards, ensuring every slewing bearing, cross roller bearing, and precision bearing meets ISO requirements. From material selection to final inspection, each process follows strict quality control to guarantee high precision, durability, and reliability. As a bearing manufacturer, LTZC is committed to the R&D of slewing bearings and providing slewing bearing solutions to customers around the world. General bearing standard: GB/T307 Slewing bearing standard: JB/2300 Ship industry standard: CB/T3669 Machinery industry standard: JB/T10471 Wind turbine bearing standard: JB/T10705

Get a quoteProduction equipment

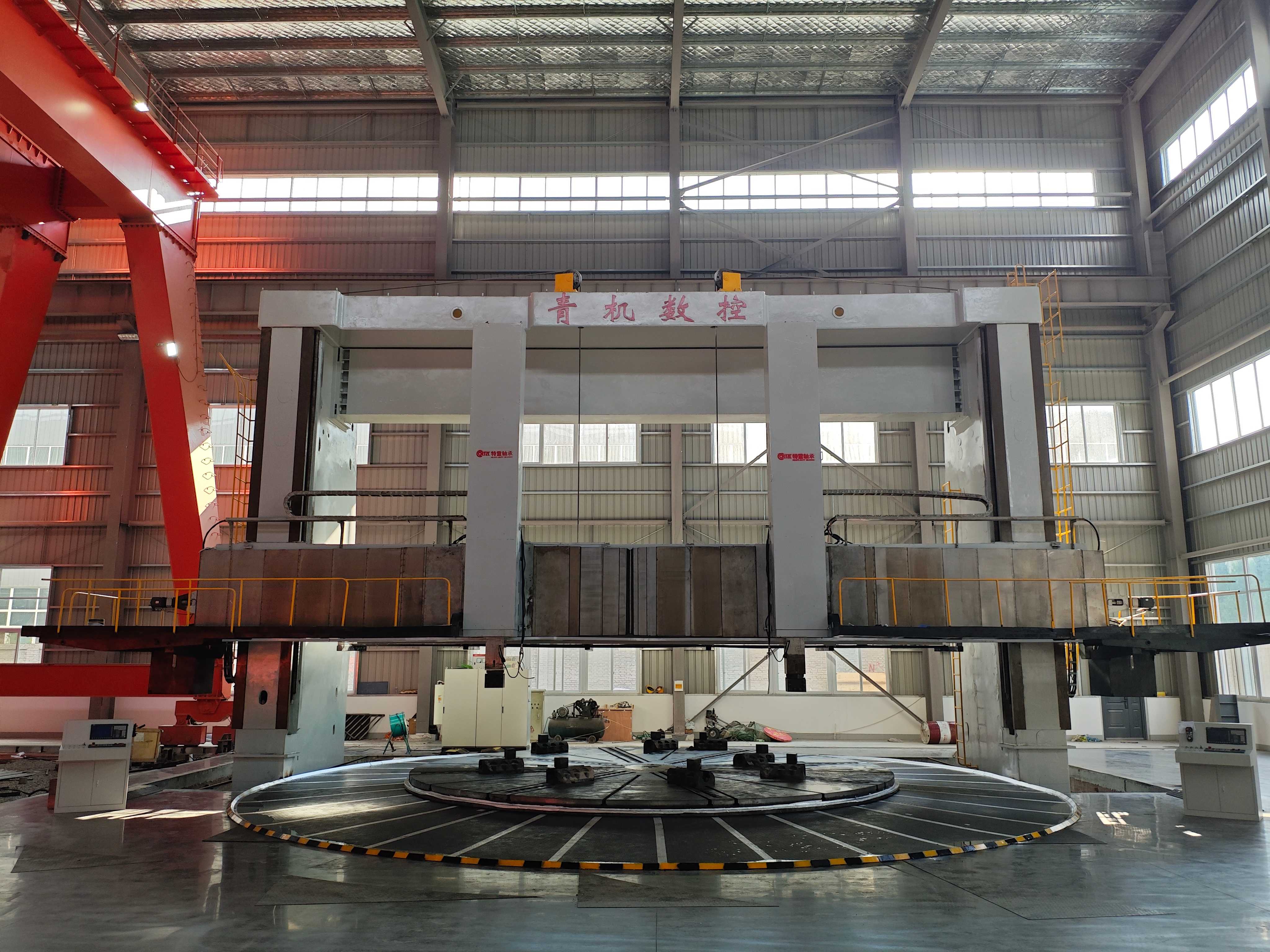

13-meter CNC vertical lathe

Processes extra-large slewing bearings with high precision, ensuring excellent roundness and stability for heavy-duty applications.

5-meter CNC vertical lathe

Machining medium-sized slewing bearings with high accuracy and smooth rotation for industrial equipment.

6-meter CNC vertical lathe

Used for precision turning of slewing bearing rings, delivering consistent quality and reliable performance.

5-meter drilling machine

Performs precise drilling on slewing bearing rings, improving assembly accuracy and production efficiency.

7-meter quenching machine

Provides uniform heat treatment for large slewing bearing rings, enhancing hardness and wear resistance.

1.6-meter gear hobbing machine

Processes small slewing bearing gears with high precision, ensuring smooth and accurate gear engagement.

10-meter gear hobbing machine

Machines large slewing bearing gears with excellent accuracy for stable transmission and long service life.

8-meter gear hobbing machine

Ensures precise cutting of slewing bearing gears, improving load capacity and product consistency.

240 CNC bearing internal grinding machine

Used for precision grinding of slewing bearing inner rings, ensuring high roundness and smooth rotation.

280 CNC Automatic Bearing Grinding Machine

Automatically grinds slewing bearing raceways with stable accuracy and improved production efficiency.

2150 CNC Bearing External Grinding Machine

Performs precise external grinding on slewing bearing rings for superior surface finish and dimensional accuracy.

1.6-meter CNC drilling and milling machine

Drills and mills slewing bearing rings with high precision, ensuring reliable assembly and performance.