Manufacturing Capability

- Home

- Company

- Manufacturing Capability

LTZC is a professional bearing manufacturer with strong production capacity and advanced technology, focusing on the research, development, and manufacturing of large-size slewing bearings and precision bearings. Our factory is equipped with state-of-the-art machining centers, heat treatment lines, and testing equipment, ensuring consistent quality and reliable performance for every product we deliver. LTZC provides customized bearing solutions and OEM services for construction machinery, wind turbines, mining equipment, and industrial automation systems. Our commitment to precision, reliability, and continuous improvement has made LTZC a trusted global partner in the field of slewing and precision bearing manufacturing.

Get a quoteCore equipment

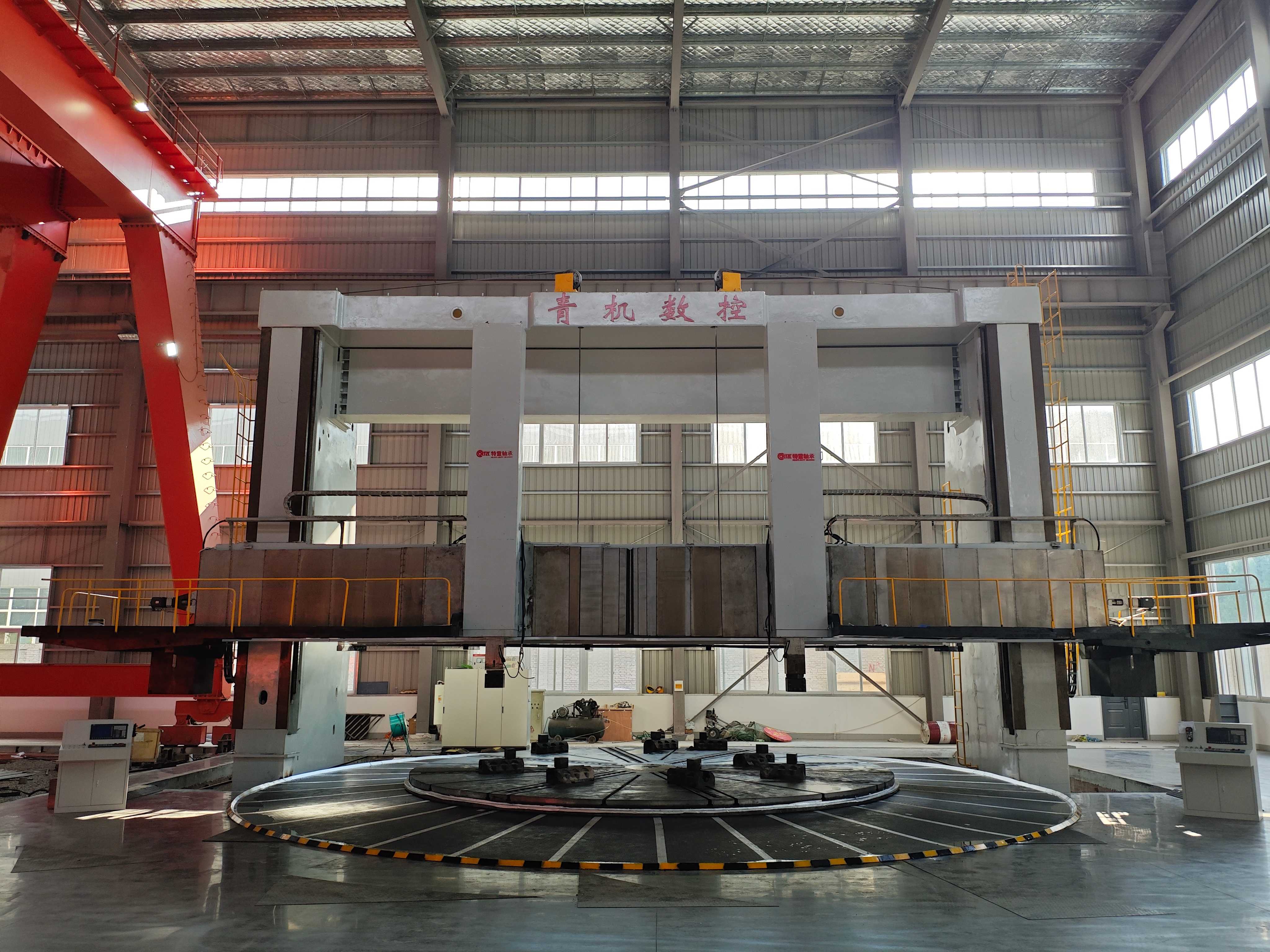

13-meter CNC vertical lathe

Manufacturing large-diameter heavy-duty bearings

5-meter CNC vertical lathe

Manufacturing high-precision slewing bearings

6-meter CNC vertical lathe

Ensure the precision of the slewing bearing

5-meter drilling machine

Precision manufacturing of slewing bearings

7-meter quenching machine

Ensures uniform hardness and durability for large slewing bearing rings.

1.6-meter gear hobbing machine

Used for precise gear cutting in small and medium slewing bearings.

10-meter gear hobbing machine

Processes large slewing bearing gears with high accuracy and stability.

8-meter gear hobbing machine

Efficiently machines heavy-duty slewing bearing gears with precision.

Machining & Heat Treatment

Bearing rough turning

Rough turning of slewing bearing rings to achieve initial shape and size with efficiency.

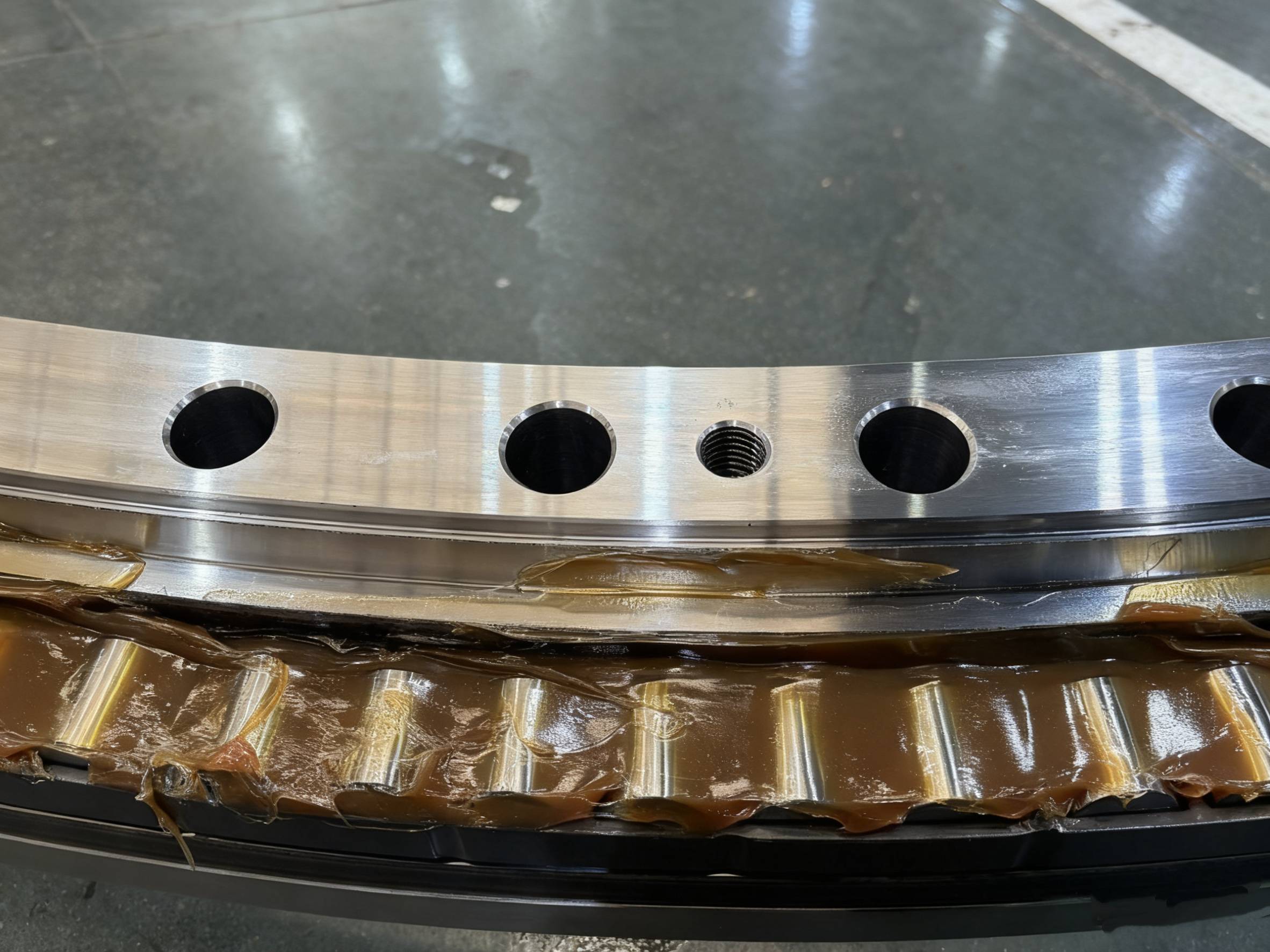

Bearing precision machining

High-precision machining of slewing bearings ensures smooth rotation and dimensional accuracy.

Bearing gear hobbing

Processes slewing bearing gears with precision, improving load capacity and transmission reliability.

Bearing drilling

Accurate drilling of slewing bearing rings for assembly precision and stable performance.

Bearing heat treatment

Advanced heat treatment enhances slewing bearing hardness, wear resistance, and load capacity.

Bearing lubrication

Proper lubrication ensures smooth rotation and long service life of slewing bearings.

Bearing runout test

Precision runout testing guarantees slewing bearing concentricity and high rotational accuracy.

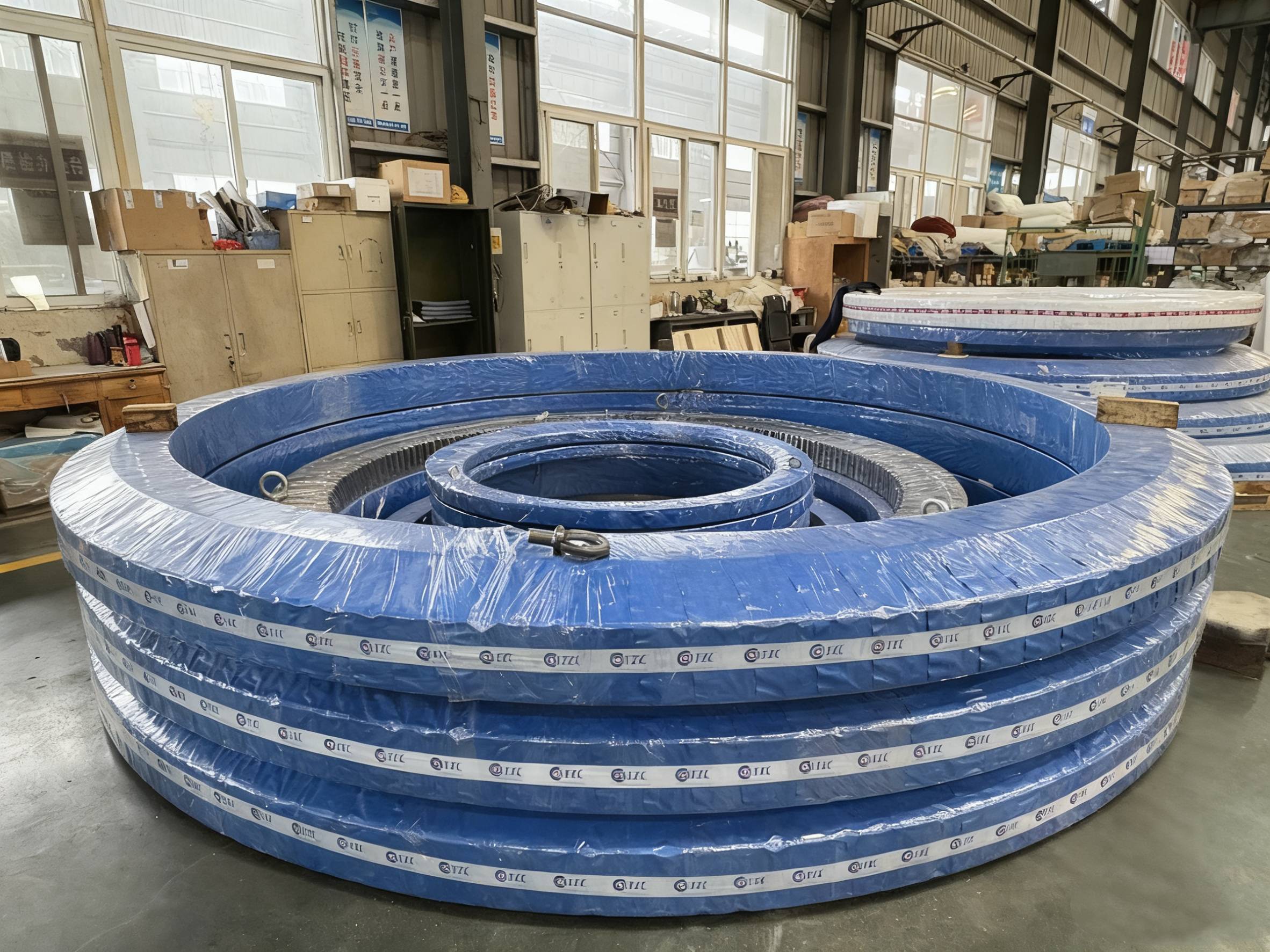

Bearing packing

Careful packing protects slewing bearings during transport, maintaining quality and reliability.

Customized bearing solutions

LTZC is a professional slewing bearing manufacturer,providing a full range of custom bearing services, including slewing rings, non-standard bearings, large bearings, thin-section bearings, crossed roller bearings, and four-point contact ball bearings. Whether the requirements are special sizes, materials, or complex operating conditions, we can provide customers with the optimal solution through professional R&D and precision manufacturing.

MoreSlewing Bearing Production Process

Packing