Marine & Defense

- Home

- Applications

- Marine & Defense

Marine & Defense Applications of LTZC Slewing Bearings

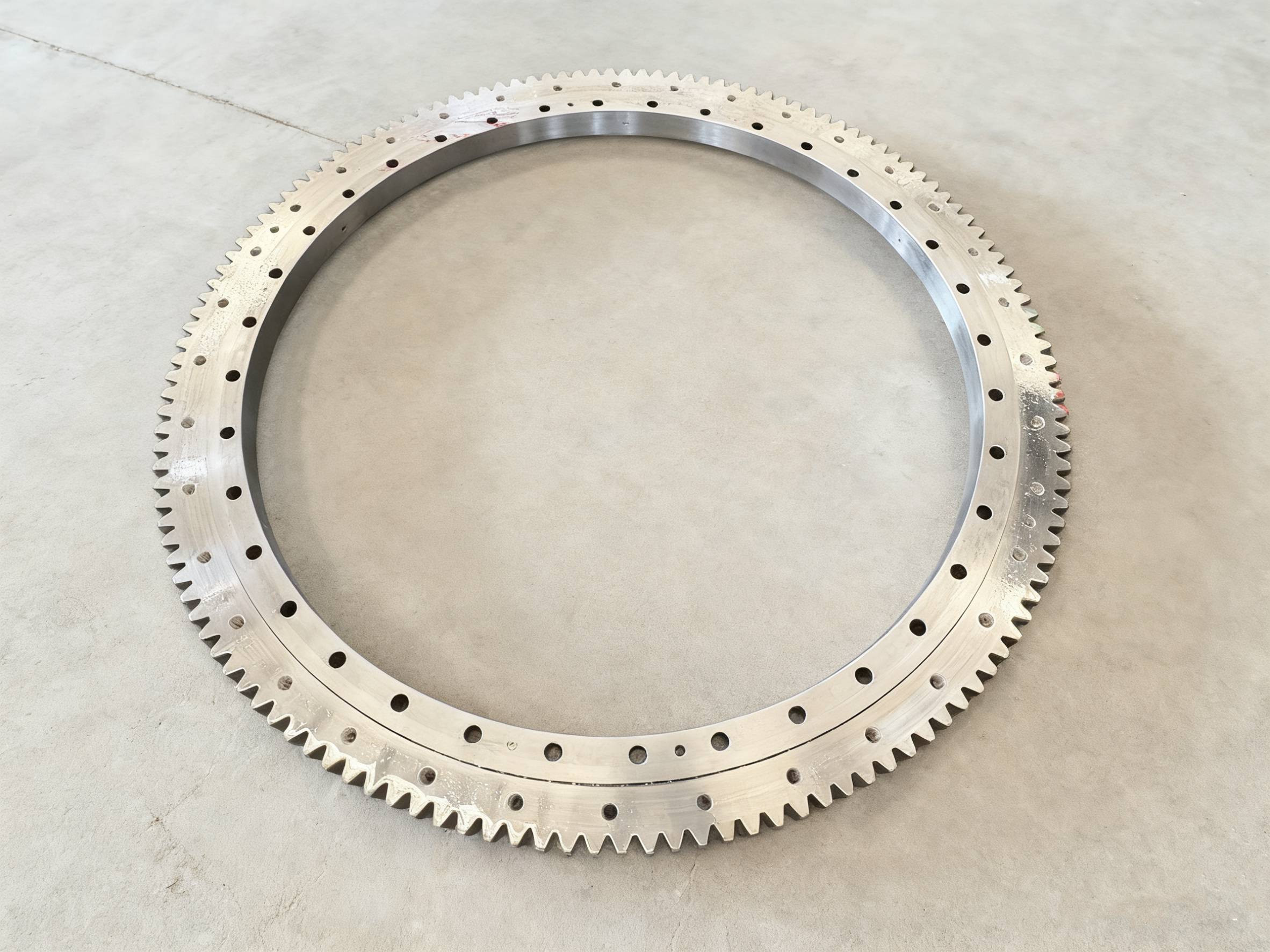

As a leading slewing bearing manufacturer, LTZC specializes in developing marine-grade and military-grade bearings designed to deliver exceptional strength, corrosion resistance, and long-term operational stability. LTZC's product range includes standard bearing and non-standard bearings, and it also offers custom bearing services, producing bearings in various sizes.With decades of engineering experience and strict adherence to international standards,LTZC bearing solutions ensure precision, reliability, and safety for critical applications across naval and defense systems.

1. The Role of Slewing Bearings in Marine & Defense Applications

Slewing bearings — also known as turntable bearings or slewing rings — enable rotational motion between two structures, supporting axial, radial, and overturning loads simultaneously. In the marine and defense sectors, these bearings must go beyond standard industrial requirements, enduring salt spray, seawater, humidity, dynamic shock loads, temperature fluctuations, and long-term vibration fatigue.

Through advanced design and high-grade materials, LTZC slewing bearings ensure stable operation and long service life, even under offshore and military conditions.

2. Marine Applications — Strength and Corrosion Resistance at Sea

In the marine sector, slewing bearings are fundamental to the safe and efficient operation of both onshore and offshore equipment. LTZC bearings feature special sealing systems and marine-grade surface treatments that protect against seawater corrosion, ensuring long-term operation without lubrication loss or metal fatigue

Key Application Fields

Offshore Cranes and Deck Machinery

Azimuth Thrusters and Steering Systems

Subsea and Drilling Equipment

Marine Radar and Satellite Communication Platforms

Engineering Focus

Corrosion Resistance: Advanced coatings (nickel-chrome, ceramic spray, polymer sealing)

Sealing Performance: Multi-layer sealing and labyrinth structures prevent contamination

Durability: Tested for over 20,000 operational hours under cyclic loads

Certifications:Designed according to DNV, ABS, and ISO 9001 marine standards

3. Defense Applications — Precision, Safety, and Mission Reliability

The defense sector demands both precision and resilience under extreme mechanical and environmental stresses. LTZC providescustomized slewing bearings for a variety of military land, naval, and aerospace systems — enabling rapid turret rotation, high shock resistance, and precise target engagement even under battlefield conditions.

Typical Defense Applications

Naval Weapon Systems

Armored Vehicle Turrets

Radar and Target Tracking Systems

Military Loading and Shipboard Equipment

Defense Engineering Advantages

High Precision and Stiffness: Optimized geometry with micron-level machining

Shock and Vibration Resistance: Internal structure for energy absorption and damping

Wide Temperature Range: Operates from –40°C to +200°C for all environments

Secure and Silent Operation: Ideal for stealth and radar-sensitive systems

Military Certifications: Compliant with MIL-STD and GJB defense standards

4. LTZC’s Technical Advantages and Manufacturing Expertise

As a trusted global bearing supplier, LTZC integrates R&D, design, production, and testing in one facility. Each stage—from raw material inspection to final assembly—is governed by traceable quality management.

Material Excellence: High-grade alloy steels (42CrMo, 50Mn) and stainless steels (SUS420, 17-4PH)

Heat Treatment & Precision Grinding: Ensures raceway hardness and long fatigue life

Dynamic Load Testing: Simulated real-world combined load verification

Corrosion Protection: Multi-layer coatings extend life by 300% in salt-fog tests

Customized Bearing: Tailored dimensions, lubrication, and seals for naval and defense projects

★LTZC Marine and Defense Bearing Solutions

Leveraging over 30 years of experience in manufacturing large slewing bearings and precision bearings, LTZC provides highly reliable, high-load-bearing, and corrosion-resistant bearing solutions for marine engineering, ship equipment, offshore platforms, naval vessels, and defense equipment.

LTZC can customize designs to meet the requirements of extreme marine conditions, salt spray environments, low-speed heavy loads, long-term static operation, high impact, and high safety levels, providing global customers with core rotating systems for sustainable operation.

① Manufacturing capability for large and heavy-duty slewing bearings (Ø 300mm–12000mm)

Suitable for ship bearing positioning devices (POD), deck lifting/slewing mechanisms, offshore platforms, etc.

② Seawater resistant, salt spray resistant, and corrosion resistant treatment: 42CrMo+ surface strengthening , special heavy-duty anti-corrosion coating (≥720h salt spray), triple sealing structure(waterproof, silt-proof, salt spray resistant)

③ High impact and low-speed heavy-duty design, thickened raceway and vibration-resistant raceway design

④ Waterproof sealing system, LTZC can be designed according to seawater immersion, splash, silt erosion and other environments: labyrinth seal, lip seal, triple combination seal

⑤ Full life cycle design and support:on-site installation guidance, load life calculation, bearing lubrication scheme, bearing fault diagnosis

5. LTZC Bearings Quality Assurance and Certifications

| Certification | Description |

|---|---|

| ISO 9001 | Quality Management System |

| ISO 14001 | Environmental Management |

| ISO 45001 | Occupational Health & Safety |

| DNV & ABS | Marine Classification Certifications |

| MIL-SPEC & CE | Defense and European Safety Compliance |

6. LTZC Technical Support and After-Sales Service

LTZC not only delivers high-quality products but also offers lifetime engineering support — from bearing selection to maintenance and replacement planning.

Expert consultation for system design and load calculation

Regular maintenance and lubrication analysis

On-site inspection and technical support