Company

- Home

- Company

About LTZC

LTZC is a leading Chinese manufacturer of slewing bearings and high-precision bearings, dedicated to providing high-performance, long-life bearing solutions for industrial, construction machinery, energy, port, and marine equipment sectors. LTZC's product range includes slewing bearings, thin-section bearings, customized bearings, slewing drives, and gears, with precision grades ranging from P6 to P0 to meet diverse needs. LTZC provides professional installation, maintenance, and technical support services to help customers reduce operating costs and improve equipment reliability. Its products are exported to more than ten countries, including Germany, Canada, and Spain, making it a trusted global partner.

Get a quote

Our Story

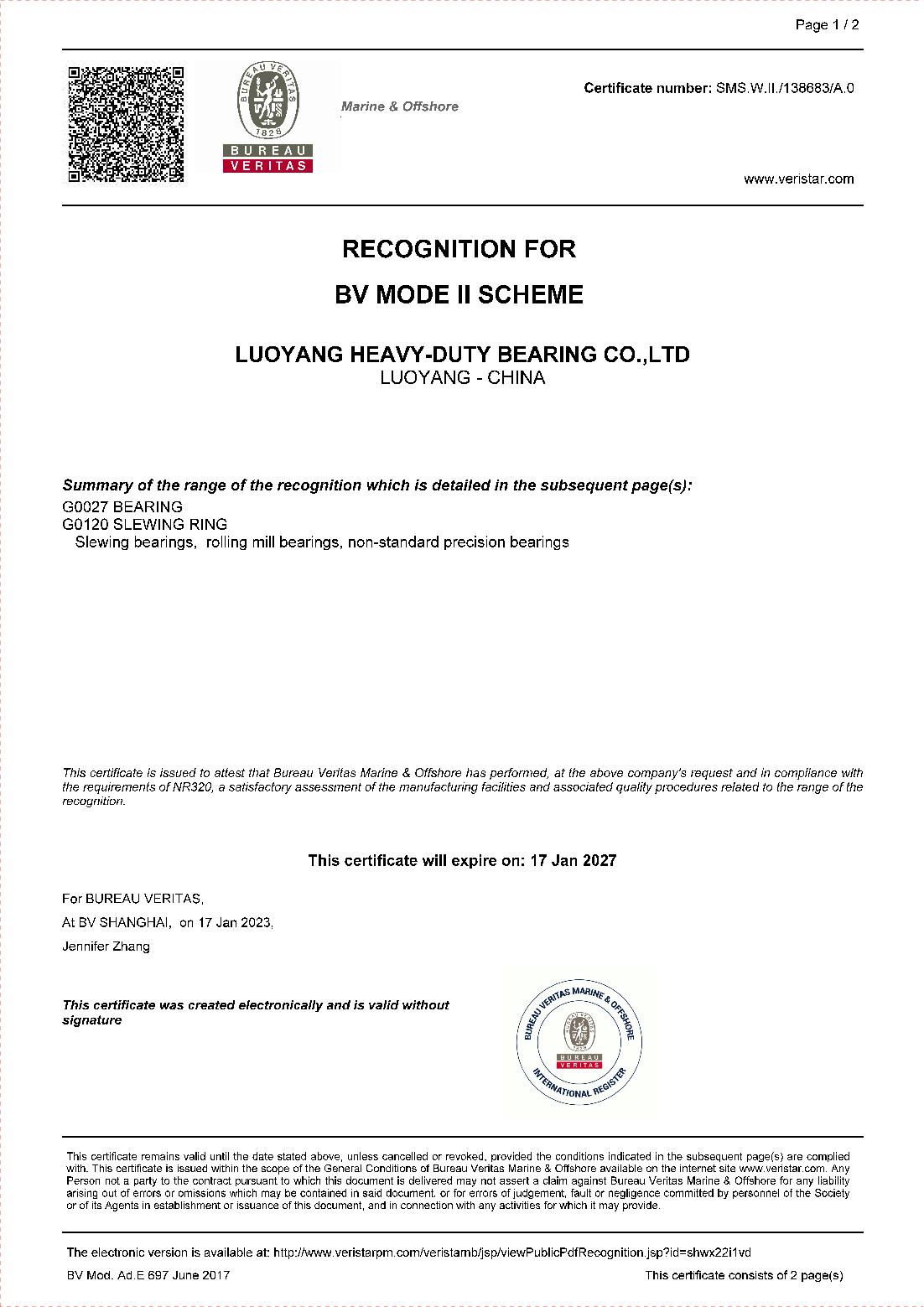

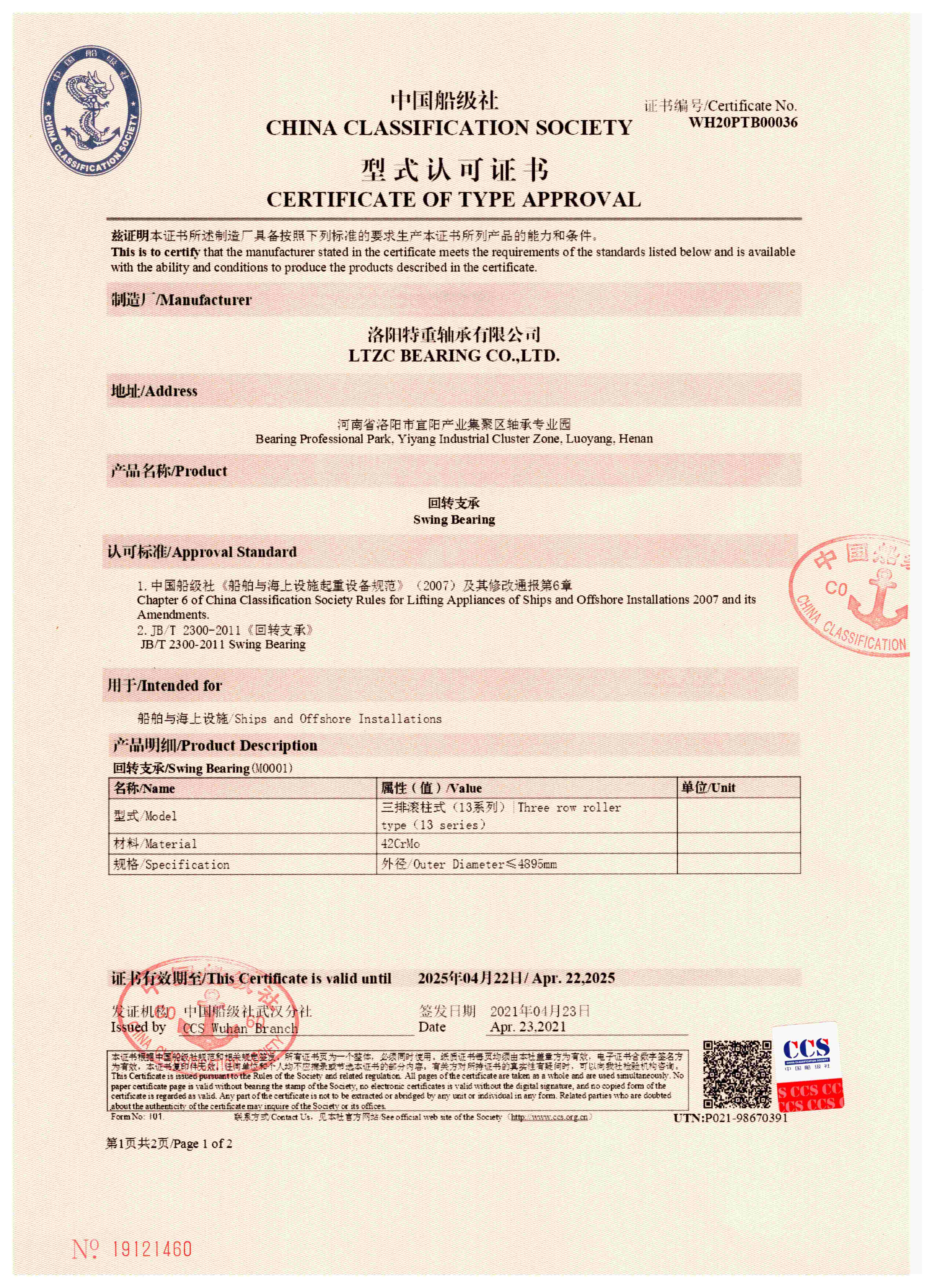

Founded in 1992, LTZC has grown into a leading Chinese manufacturer of slewing bearings and precision slewing systems after more than 30 years of development. The company focuses on the research and development and manufacturing of core load-bearing and rotational technologies, committed to providing global customers with highly reliable and high-performance products. LTZC's products are widely used in demanding fields such as offshore wind power, construction machinery, industrial robots, port equipment, and aerospace. In the future, LTZC will continue to provide slewing bearing solutions to global customers through rigorous engineering technology and continuously improving manufacturing capabilities.

Get a quoteOur factory

Bearing precision machining

Surface roughness Ra≤0.2μm ensures stable operation.

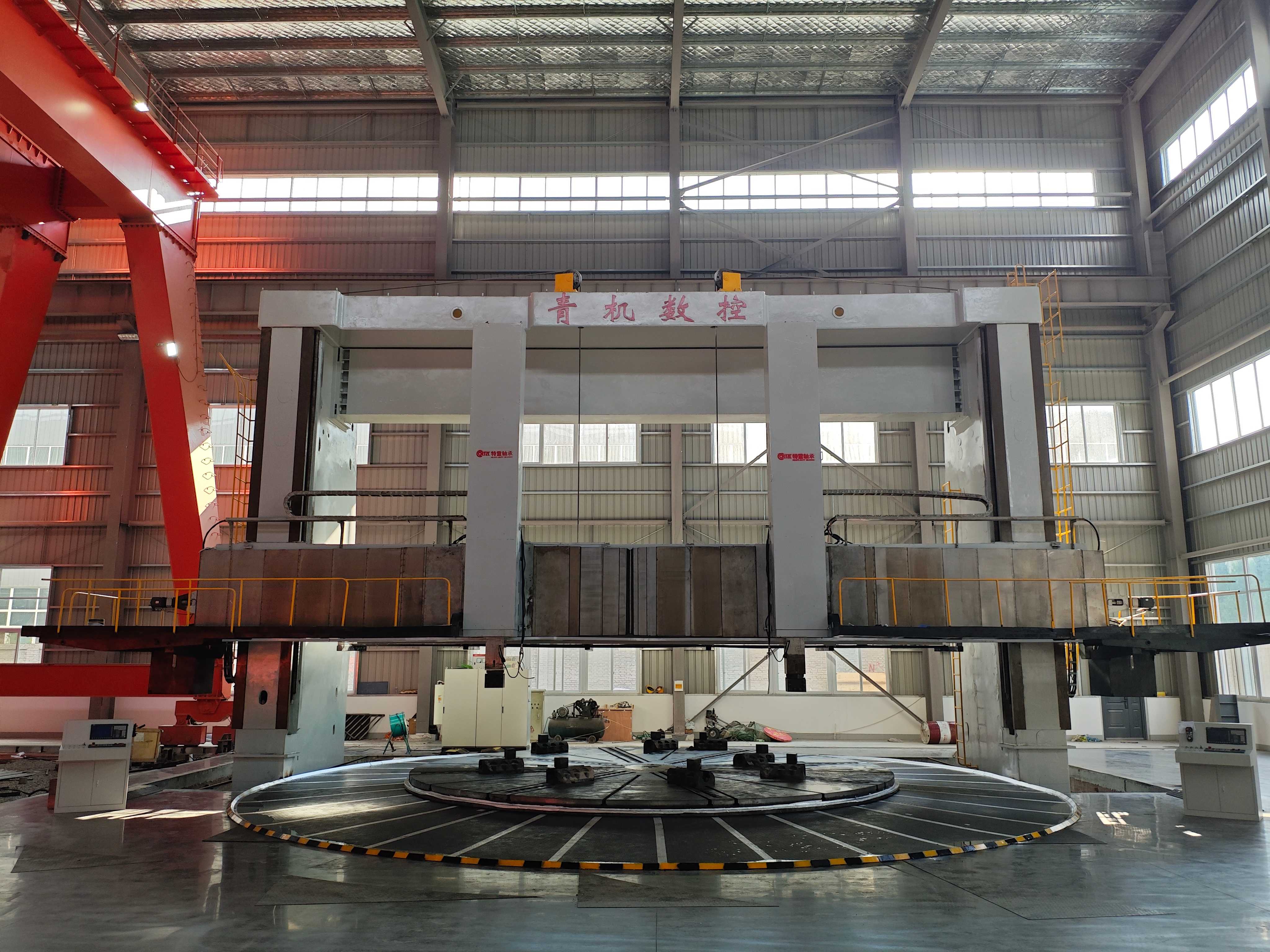

13-meter large slewing bearing lathe

LTZC offers a wide range of slewing bearings in various sizes and types.

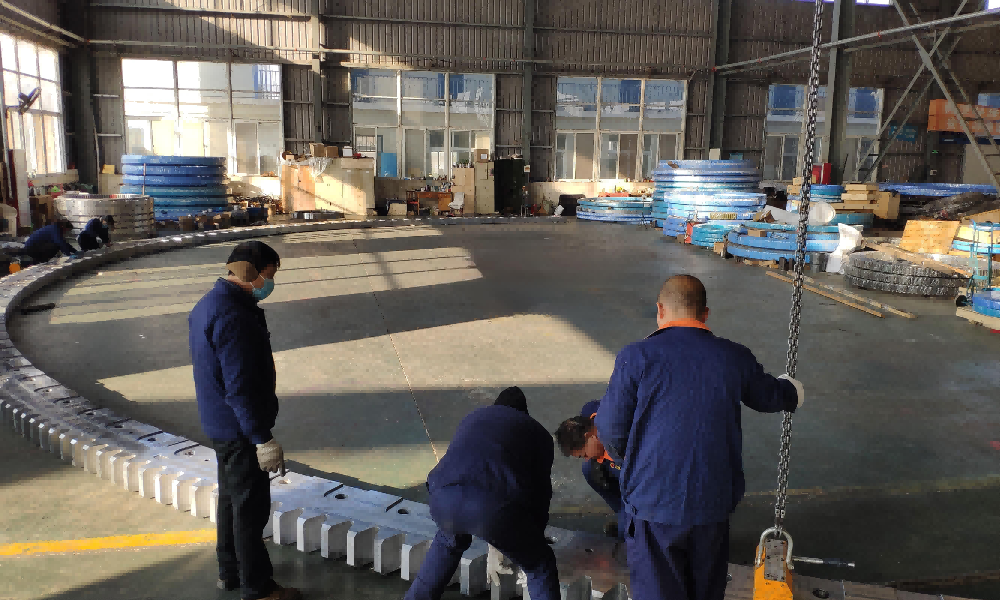

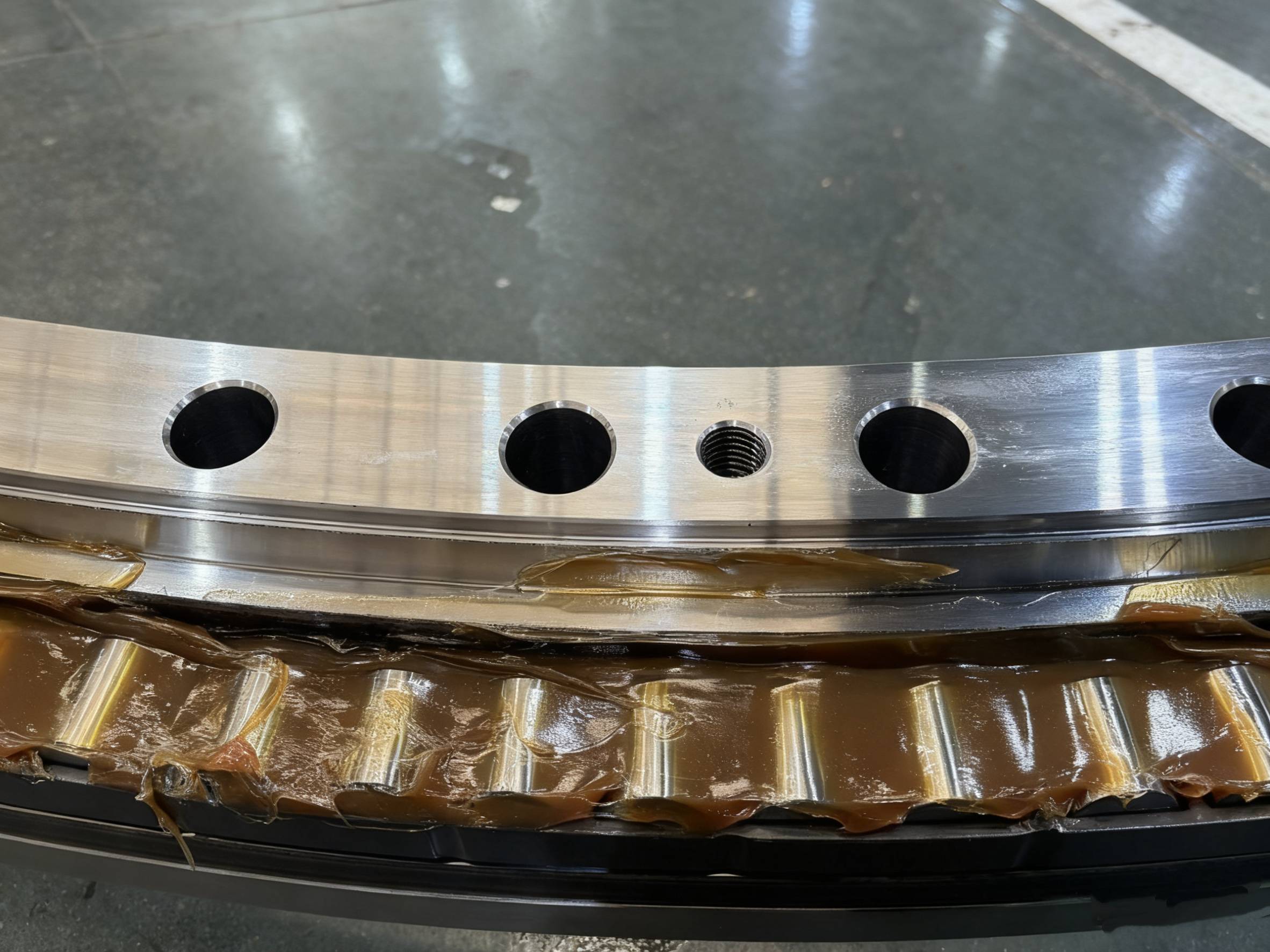

Precision slewing bearing assembly

LTZC engineers provide bearing CAD drawings and installation instructions.

slewing bearing manufacturers

LTZC has over 20 years of experience in bearing R&D.

Our production process

Bearing dye penetrant testing

LTZC strictly controls the production process to ensure high bearing quality.

Bearing surface heat treatment

Increase bearing surface hardness and extend bearing service life

Bearing seal ring

LTZC delivers customized bearing seal solutions to enhance bearing performance.

Bearing grease

LTZC bearing grease offers anti-wear performance, and reliable protection

Customized bearing solutions

LTZC is a professional slewing bearing manufacturer,providing a full range of custom bearing services, including slewing rings, non-standard bearings, large bearings, thin-section bearings, crossed roller bearings, and four-point contact ball bearings. Whether the requirements are special sizes, materials, or complex operating conditions, we can provide customers with the optimal solution through professional R&D and precision manufacturing.

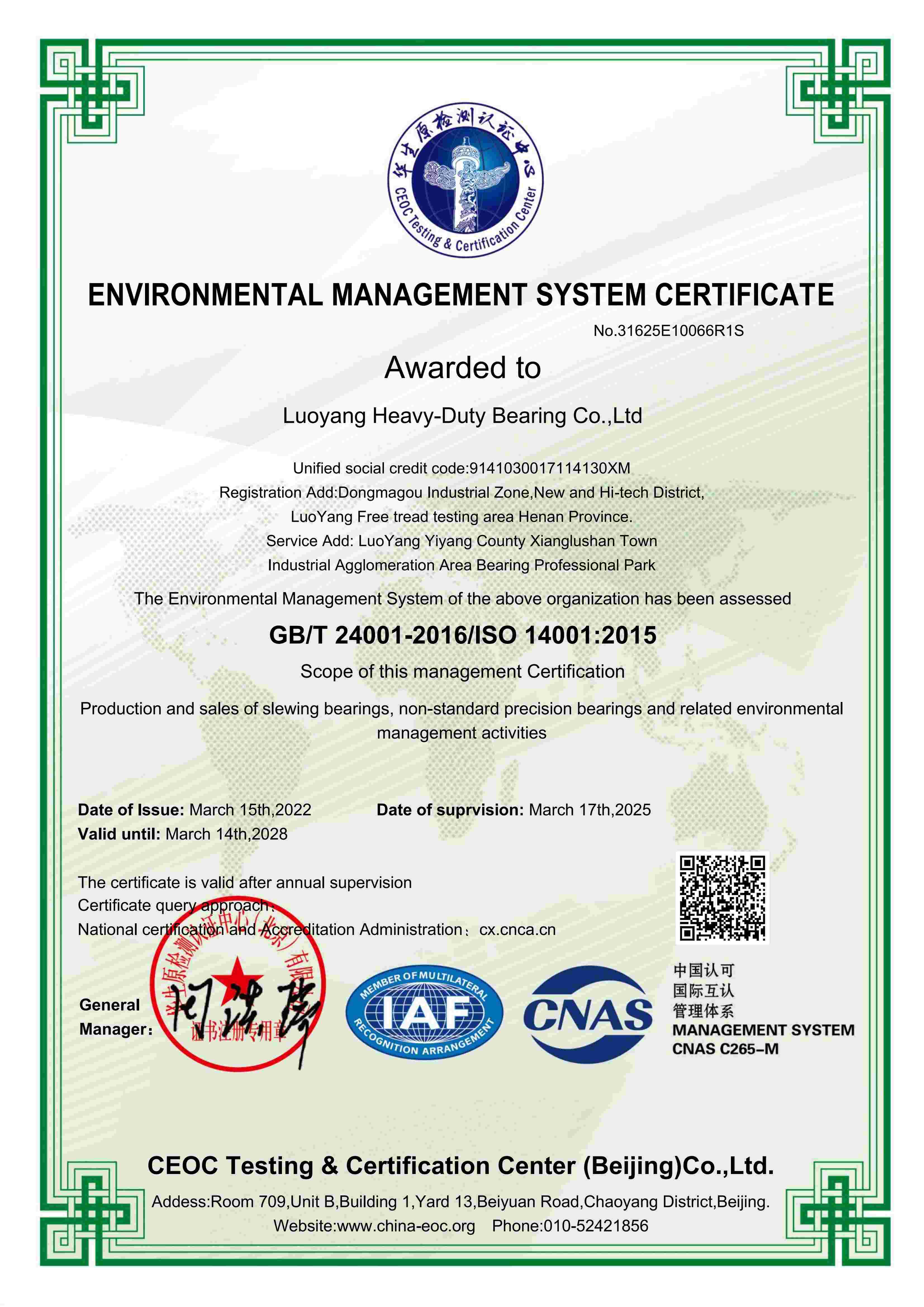

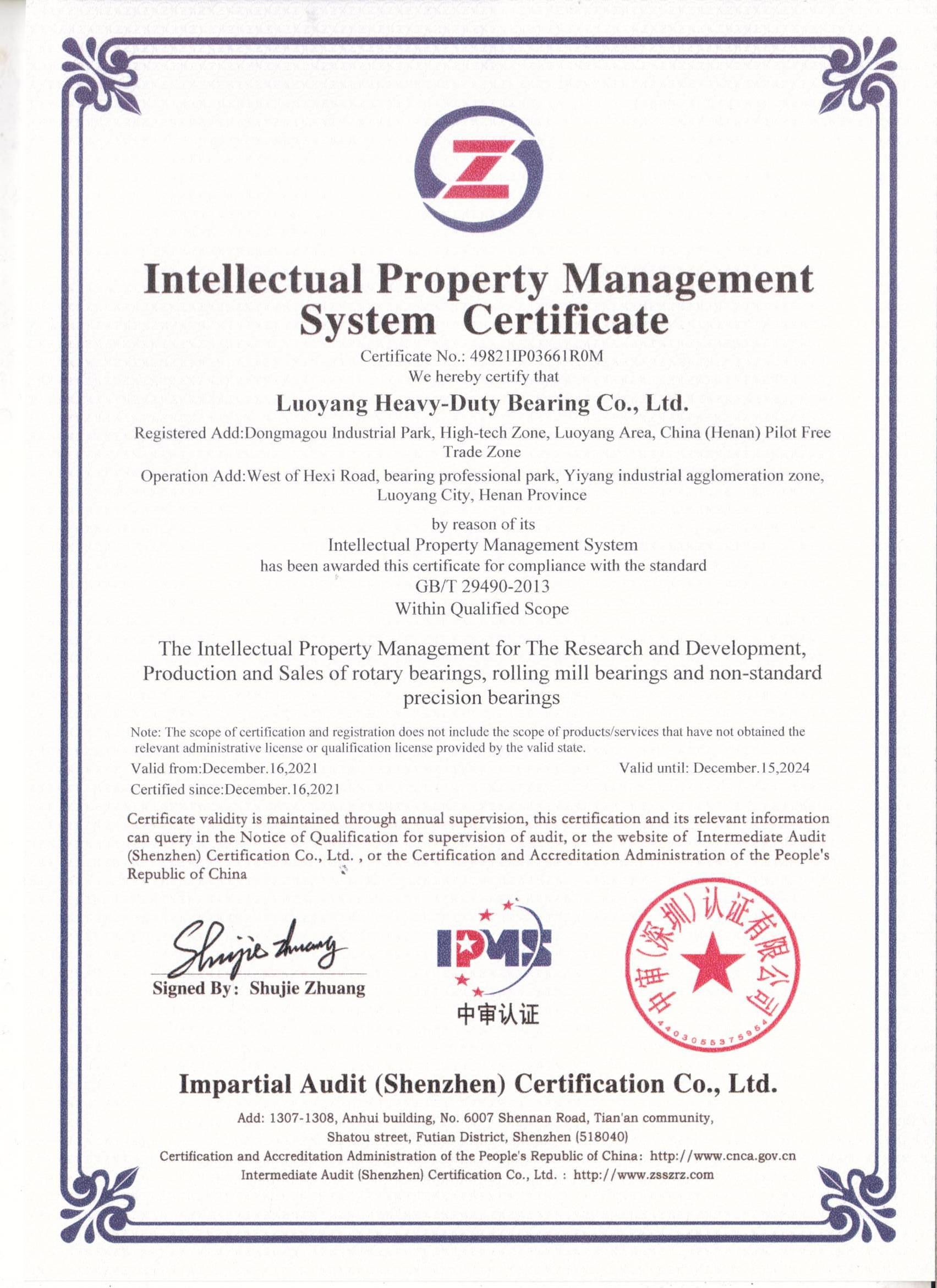

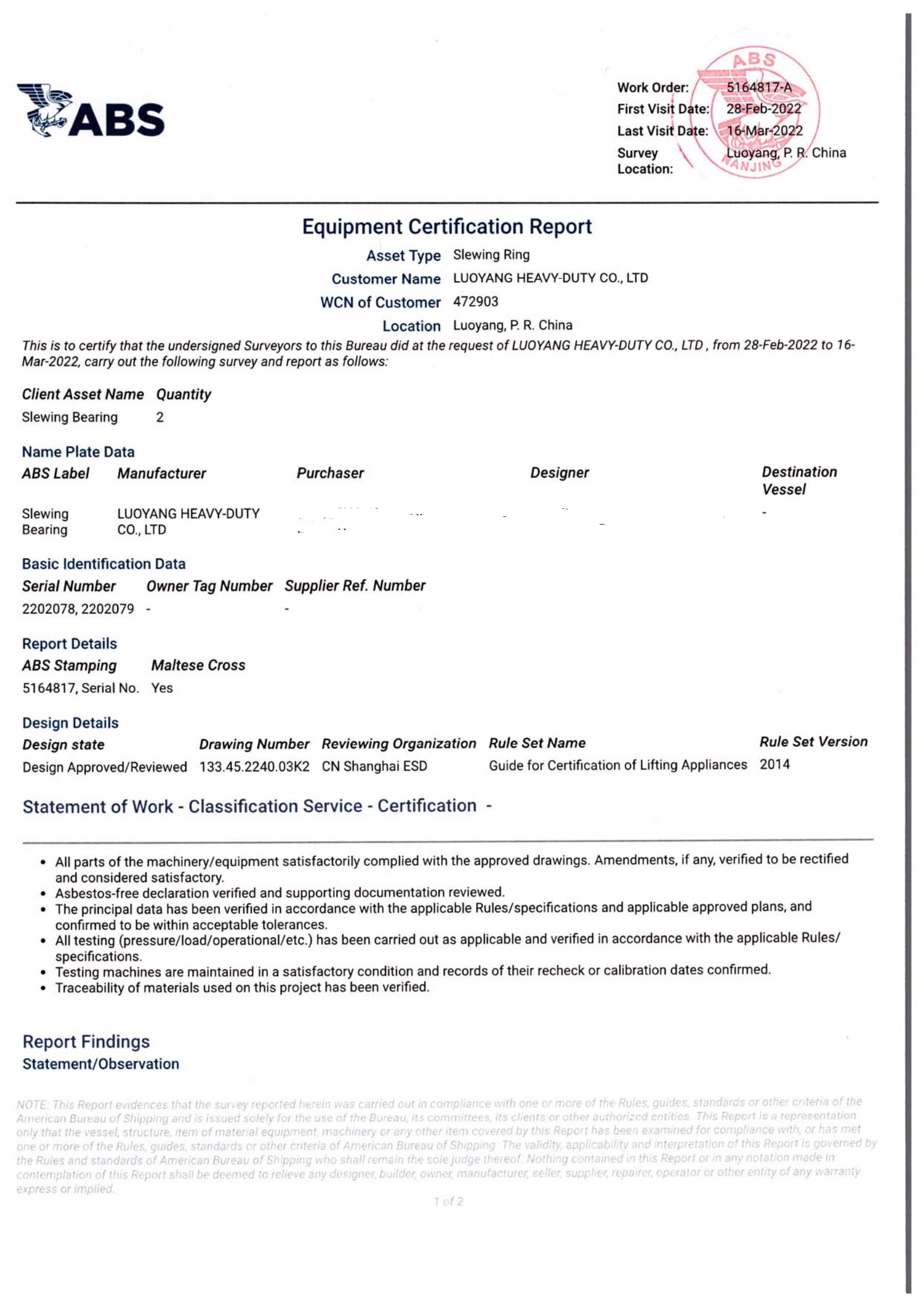

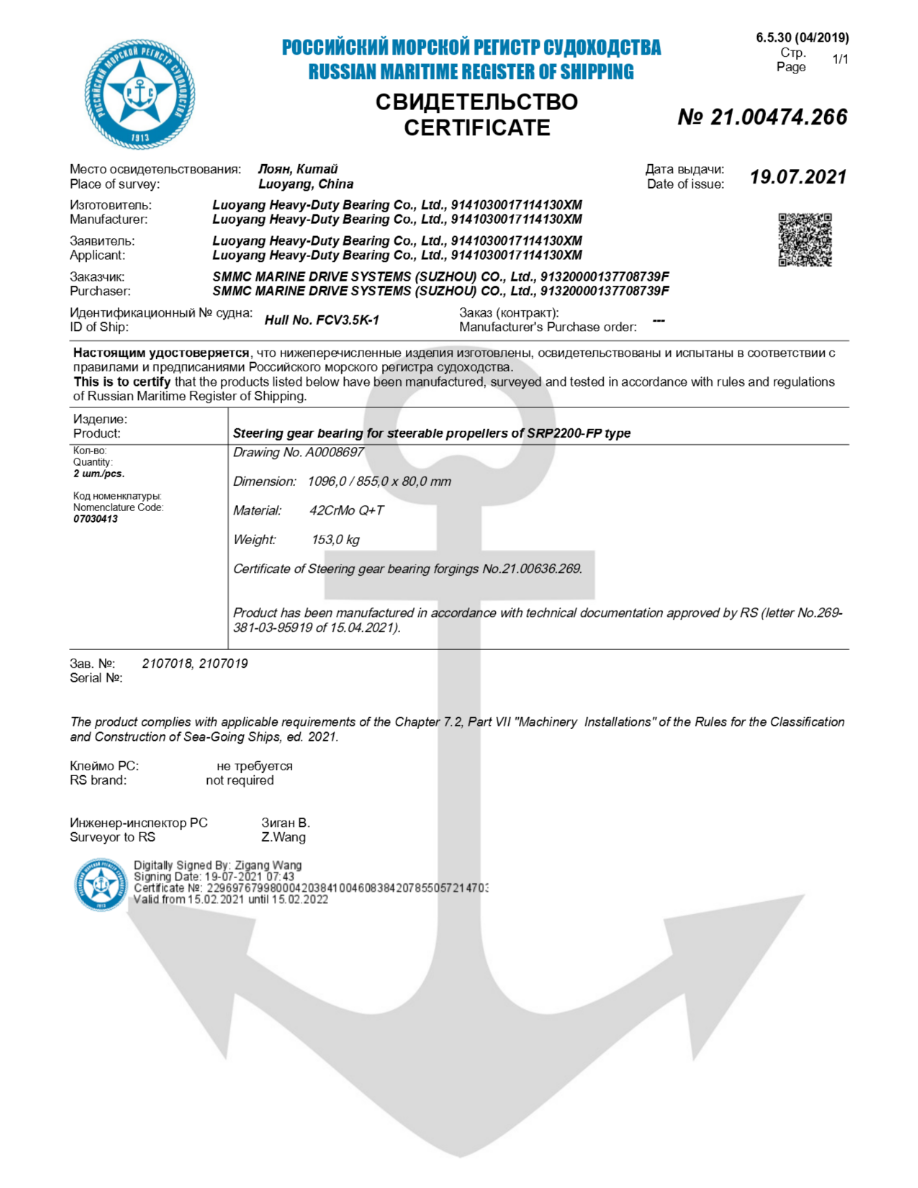

MoreLTZC possesses a complete production system, from raw material cutting, forging, heat treatment, precision bearings machining, gear quenching, bearing assembly to testing. High product qualification rate, stable delivery time, and support for rapid delivery and urgent orders are ensured. Equipped with CNC machining centers, CNC gear grinding, and ultra-precision inspection platforms, LTZC achieves slewing bearing precision grades P6–P0 and gear grades 6–4. All products follow ISO9001, 14001, and 45001 systems for reliability and traceability. LTZC excels in steel material selection and processing, providing heavy-duty, wear-resistant, and impact-resistant solutions. Carburizing and induction hardening processes significantly boost fatigue life, wear resistance, and deformation resistance. LTZC offers highly customized solutions including large-size heavy-duty bearings, non-standard slewing bearings, segmented gear rings/tracks, sealing systems, slewing drives, and precision gears、thin-section bearings. With 30+ years of engineering experience, LTZC provides bearing selection, bearings installation guidance, operating condition analysis, life prediction, bearing 3D drawings and failure optimization to improve reliability and reduce maintenance costs. LTZC as a China's leading slewing bearing manufacturer exporting products to Europe, North America, Southeast Asia, the Middle East, and more. With stable quality, quick response, strong project experience, and professional technical support ,LTZC maintains long-term cooperation with global high-quality clients.LTZC's Core Advantages

1. Independent Manufacturing Capability

2. High-Precision Bearing Machining

3. Advanced Manufacturing Processes

4. Strong bearing Customized Capabilities

5. Professional Technical Team

6. Global Trusted Partner