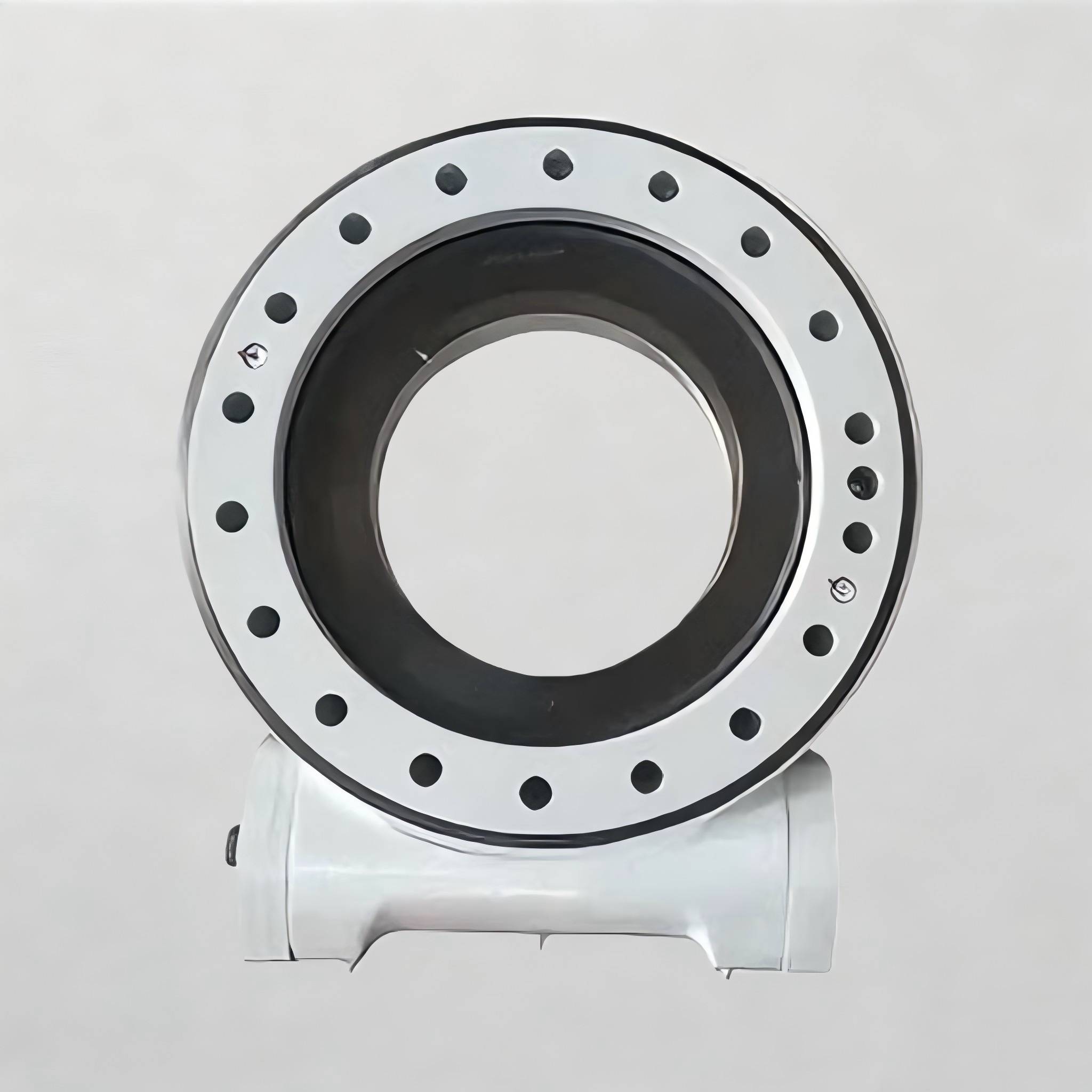

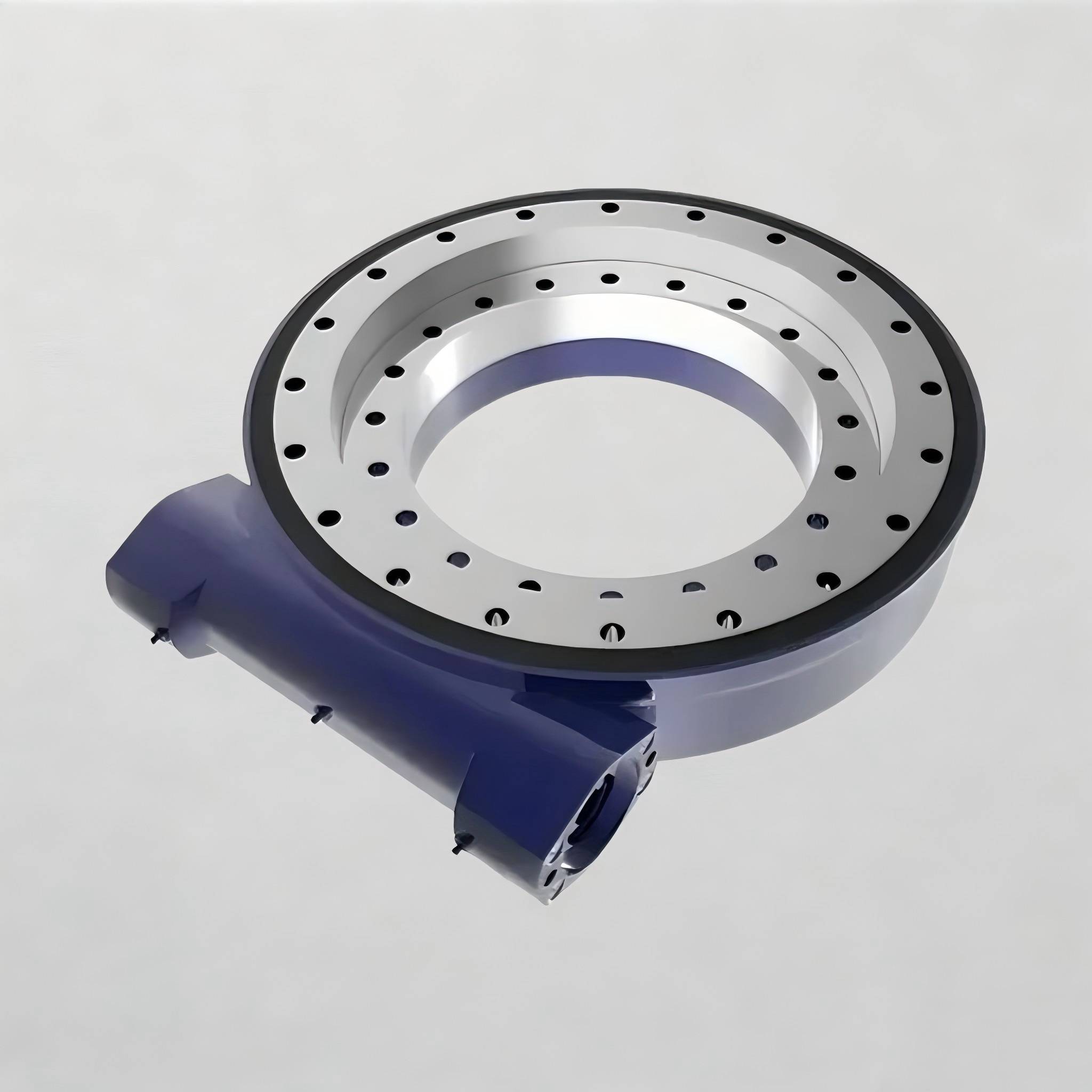

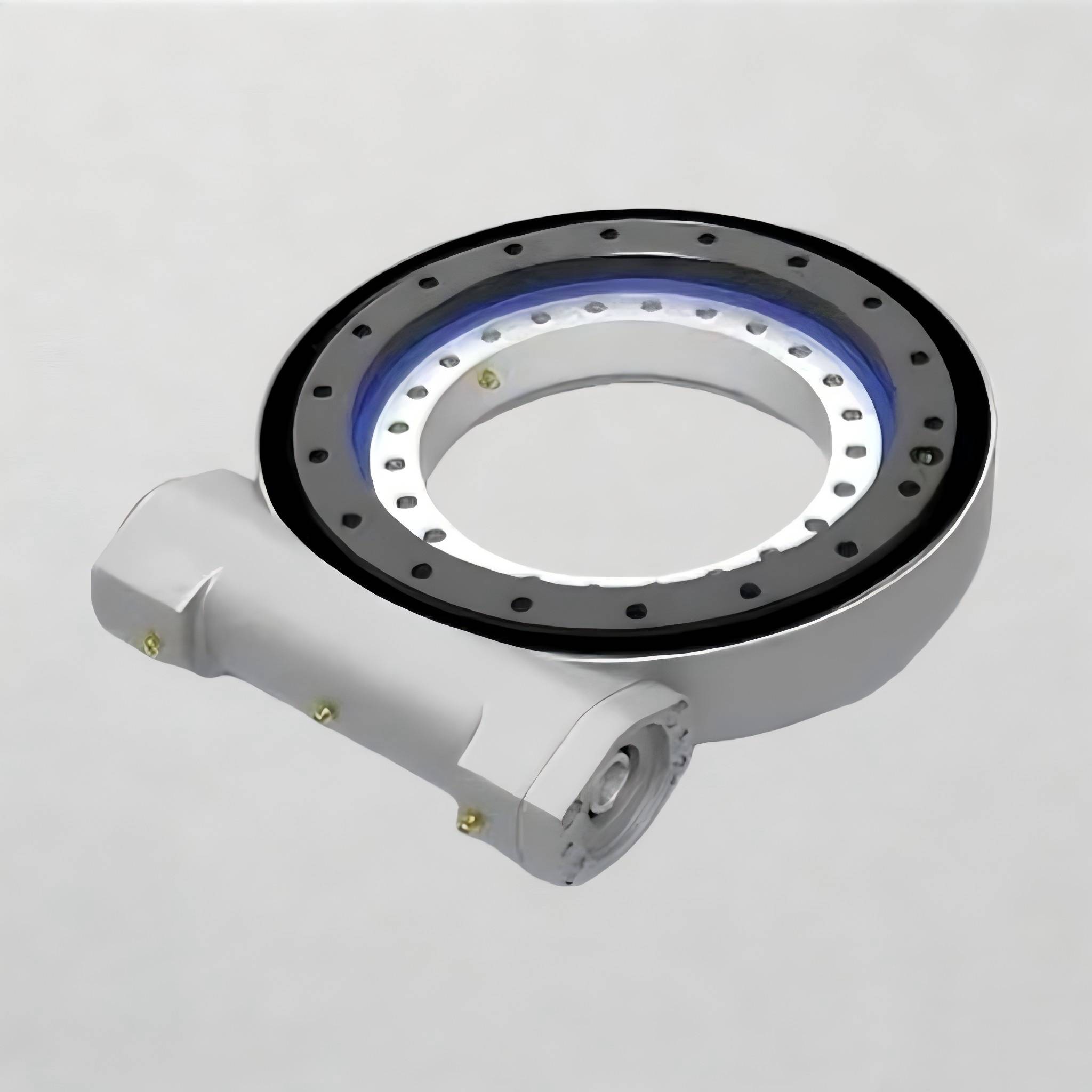

Schneckengetriebe-Drehantrieb

LTZC Worm gear slewing drive advantages

Stable Transmission, Low Noise:

The precision-machined slew gears, in conjunction with the LTZC slewing bearing,provide a smooth meshing effect and lower noise levels, making it suitable for continuous operation.

High Positioning Accuracy, Smoother Adjustment:

The worm gear structure offers excellent speed reduction, and combined with LTZC low-backlash control technology, it achieves precise angle positioning and stable speed control.

Reliable Sealing Protection, Suitable for Outdoor Environments:

The fully enclosed structure withmultiple sealing designseffectively resists dust, moisture, and salt spray, making it suitable for photovoltaic tracking systems, engineering equipment, and marine equipment.

Modular Design, High Adaptability:

The LTZC worm gear slew drive is compatible with hydraulic motors, servo motors, and stepper motors, allowing customers to flexibly integrate different drive methods.

Stable Quality, Meets International Standards:

LTZC bearingshave over 20 years of experience in bearing and drive R&D. LTZC bearing products undergo rigorous material testing, tooth surface hardness control, and whole-machine inspection, and are supported by ISO and classification society standards to ensure product reliability and consistency.

LTZC Worm gear slewing drive features

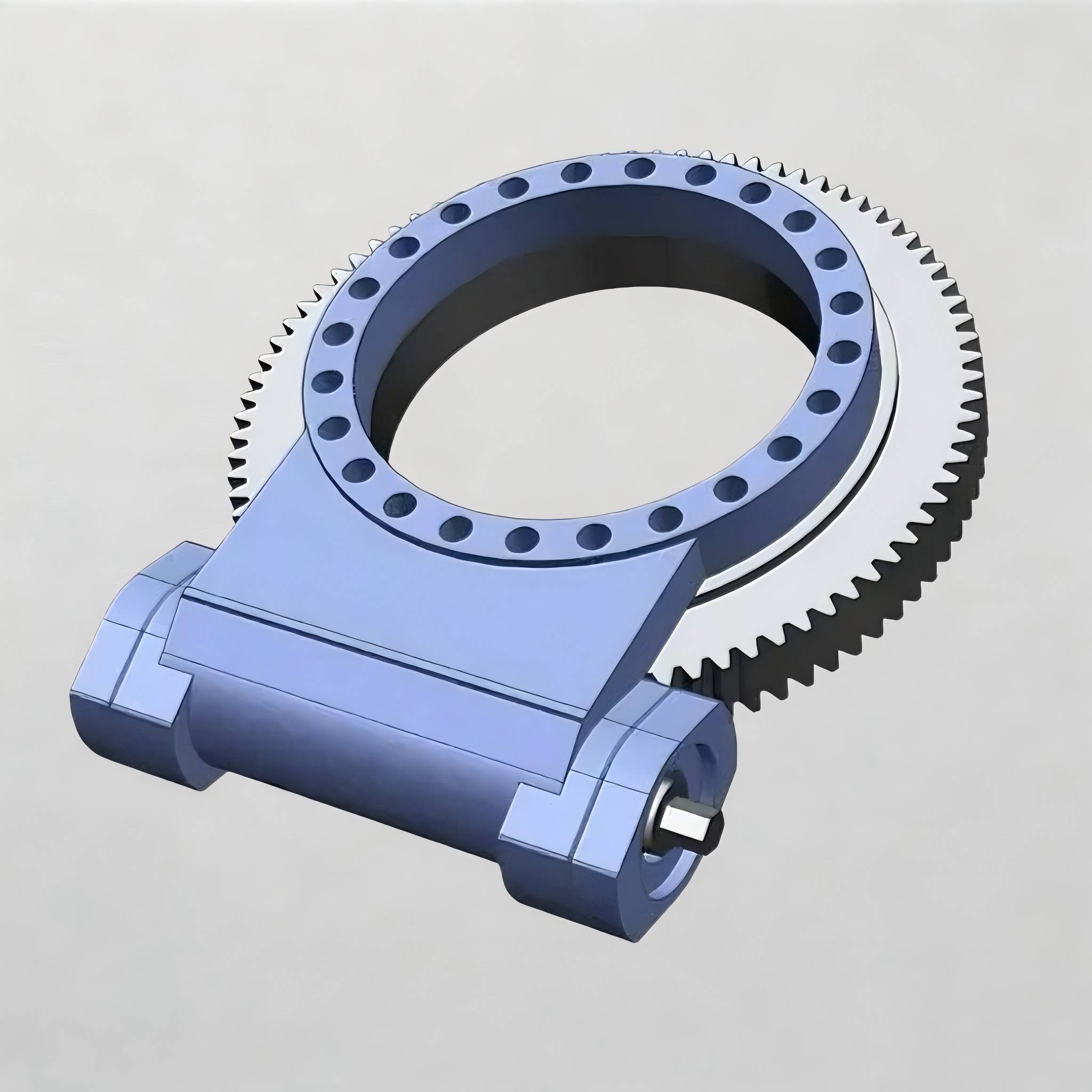

A worm gear slewing drive is a rotary transmission device that integrates a power drive source. It mainly consists of a worm, worm wheel, slewing bearing, housing, and power source. It transmits motion and power through the meshing of the worm and worm wheel gear. The axes of the worm and worm wheel are typically arranged at a 90° angle in space.

1. High integration: It integrates multiple functions such as rotation, driving, and reduction, resulting in a compact and multi-functional structure.

2. Strong load-bearing capacity: DerDrehlager primarily handles rotation and heavy loads, and can simultaneously withstand axial force, radial force, and overturning moment.

3. Self-locking performance: When the lead angle of the worm is less than the equivalent friction angle between the meshing tooth surfaces, the device has a self-locking function, meaning that the worm can drive the worm wheel, but the worm wheel cannot drive the worm, providing a safety protection function.

Get a quote for LTZC bearings View LTZC quality and certifications View LTZC manufacturing capabilities

Worm gear slewing drive

|

Type

|

Output

|

Overturning

|

Holding

|

Axial Static

|

Radial Static

|

Axial Dynamic

|

Radial Dynamic

|

Reduction Ratio

|

Accuracy Class

|

Gewicht

|

|

Torque

|

Moment

|

Torque

|

Load

|

Load

|

Load

|

Load

|

|

|

|

|

WE9

|

8 kN.m

|

35.6 kN.m

|

38.7 kN

|

578 kN

|

215 kN

|

136 kN

|

115 kN

|

62:1

|

<=0.15°

|

48.5 Kg

|

|

5904 lbf.ft

|

26300 lbf.ft

|

29000 lbf

|

12900 lbf

|

48300 lbf

|

30600 lbf

|

25900 lbf

|

|

WE12

|

9.5 kN.m

|

57 kN.m

|

43 kN.m

|

760 kN

|

280 kN

|

190 kN

|

148 kN

|

79:1

|

<=0.15°

|

61 Kg

|

|

7011 lbf.ft

|

42100 lbf.ft

|

32000 lbf.ft

|

17100 lbf

|

62900 lbf

|

42700 lbf

|

33300 lbf

|

|

WE14

|

10.8 kN.m

|

71.2 kN.m

|

48 kN.m

|

960 kN

|

360 kN

|

230 kN

|

200 kN

|

86:1

|

<=0.13°

|

68 Kg

|

|

7970 lbf.ft

|

52600 lbf.ft

|

35000 lbf.ft

|

215800 lbf

|

80900 lbf

|

51700 lbf

|

44900 lbf

|

|

WE17

|

12.96 kN.m

|

142.4 kN.m

|

72.3 kN

|

1166 kN

|

425 kN

|

280 kN

|

231 kN

|

104:1

|

<=0.1°

|

90 Kg

|

|

9564 lbf.ft

|

105000 lbf.ft

|

5340 lbf.ft

|

262000 lbf

|

978800 lbf

|

62900 lbf

|

51900 lbf

|

|

WE21

|

28.7 kN.m

|

203 kN.m

|

105.8 kN

|

1589 kN

|

640 kN

|

385 kN

|

335 kN

|

90:1

|

<=0.1°

|

169 Kg

|

|

21180 lbf.ft

|

150000 lbf.ft

|

78100 lbf.ft

|

359000 lbf

|

144000 lbf

|

87000 lbf

|

75000 lbf

|

|

WE25

|

34.2 kN.m

|

310 kN.m

|

158.3 kN

|

2360 kN

|

945 kN

|

590 kN

|

470 kN

|

104:1

|

<=0.1°

|

199 Kg

|

|

25240 lbf.ft

|

229000 lbf.ft

|

117000 lbf.ft

|

531000 lbf

|

212000 lbf

|

133000 lbf

|

106000 lbf

|