Slewing Bearings

- Home

- Products

- Slewing Bearings

Slewing Bearings

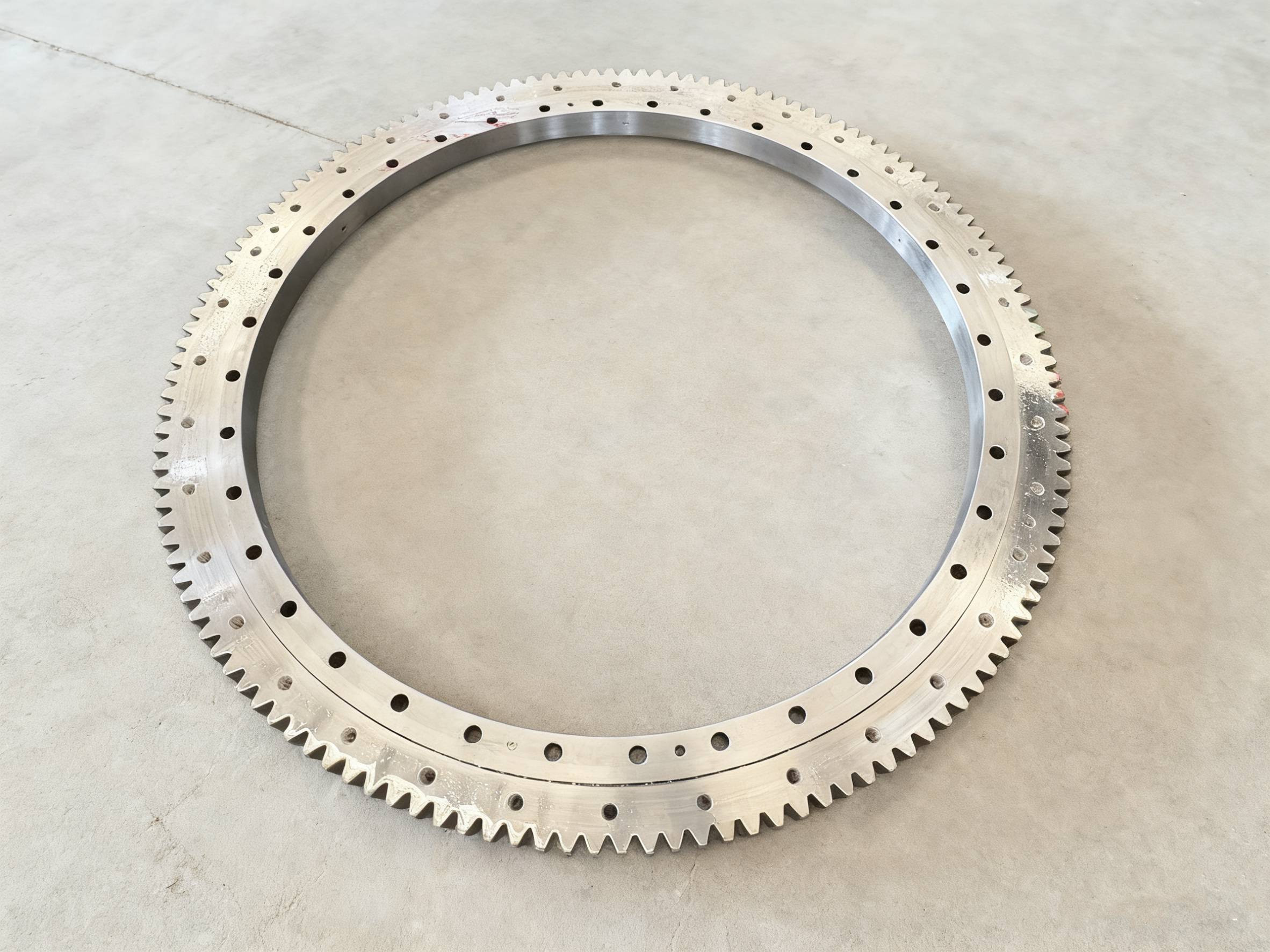

LTZC is a leading Chinese manufacturer of slewing bearings, with products holding ISO 9001, 14001, 45001, CCS, BV, and ABS certificates. LTZC can provide customized slewing bearings, including those with large diameters, complex structures, and demanding load conditions. Our product range covers four-point contact ball bearings, crossed roller bearings, three-row roller slewing bearings, split bearings, flange bearings, gear ring, segmented tracks, sealing rings, and slewing structural components.

LTZC slewing bearings meet accuracy grades from p0 to p5. LTZC supports full customization of materials, heat treatment, gear module, sealing systems, and mounting structures, providing optimized solutions for applications such as wind turbines, cranes, excavators, offshore platforms, automation equipment, robotics, mining machinery, and heavy engineering systems.

Get a Quote

Single-row ball slewing ring

Single-row ball slewing bearings are a commonly used lightweight bearing type. They are primarily co

Learn More Get a Quote

Double-row ball slewing bearing

Double-row ball bearings have two rows of rollers that make eight-point contact with the raceway.

Learn More Get a Quote

Cross Roller Slewing Ring

LTZC crossed roller slewing bearings offer high performance, stable operation, and heavy load capaci

Learn More Get a Quote

Three-row roller slewing Ring

Three-row roller slewing bearings have a higher load capacity than crossed roller slewing bearings.

Learn More Get a Quote

Ball-Roller Combined Slewing Ring

LTZC is a manufacturer of slewing bearings, offering internal gear, external gear, and gearless bear

Learn More Get a Quote

Split Slewing Bearing

Split slewing bearings are convenient for transportation and installation.

Learn More Get a Quote

Flanged Slewing Bearing

Flange slewing bearing is a slewing bearing with a flange as the mounting surface.

Learn More Get a Quote

Customized Bearings

Ltzc is a professional manufacturer of slewing bearings, providing high quality slewing bearings

Learn More Get a QuoteWhat is slewing bearing?

Slewing bearings, also known as slewing rings, are key components in the rotation of heavy machinery and also bear the overturning moment generated during rotation. Their core function is to provide stable connection and rotational support for two components that require relative rotational movement. Their core structure consists of an inner ring, outer ring, rolling elements, spacers, seals, and lubrication system. Slewing bearings can be classified in several ways: firstly, according to the gear structure, into internal gear slewing bearings, external gear slewing bearings, and gearless slewing bearings; secondly, according to the raceway, into single-row slewing bearings, double-row slewing bearings, and three-row slewing bearings; and thirdly, according to the rolling elements, into roller slewing bearings and ball slewing bearings.

What is slewing bearing used for?

1. Engineering Machinery Field – Widest Application

Excavators, cranes, pile drivers, rotary drilling rigs, graders, road rollers, drilling rigs

2. New Energy Field

Wind power equipment and photovoltaic and solar thermal equipment

3. Port and Logistics Machinery Field

Port cranes, stacker-reclaimers, ship equipment

4. Medical and Aerospace Field

CT medical equipment, scanners, radar satellites, large telescopes

5. Other General Machinery Fields

Automated warehousing equipment, metallurgical machinery, mining machinery

How do slewing bearings work?

The working principle of slewing bearings is based on the frictional movement of rolling elements within the raceways, enabling the relative low-speed rotation of two components. During operation, they experience a complex load comprising axial force, radial force, and overturning moment. The design of the raceways and rolling elements distributes these three moments across the entire annular contact surface, allowing them to bear multi-dimensional loads. Slewing bearings are designed with single-row, double-row, and triple-row raceways, which differ significantly in their load-bearing capacity, with triple-row raceways offering the highest load capacity. Compared to ordinary bearings, the advantage of slewing bearings lies in their ability to simultaneously address both "load bearing" and "rotation" requirements without the need for additional bearing housings and support structures. This is a key reason why they are essential components in large equipment such as construction machinery and wind power equipment.

How to choose the right slewing bearing?

I. Clearly define the operating conditions, determining the load requirements, rotational frequency, rotational speed, and angle of the bearing.

II. Confirm the drive method of the slewing bearing: geared drive (gear module, number of teeth, gear accuracy) or gearless drive.

III. Select the bearing structure type based on load and accuracy requirements: ball bearings for light loads and small equipment; roller bearings for heavy loads and precision equipment; and three-row roller bearings for extremely heavy loads.

IV. Match the installation conditions and structural design, determining the bearing installation dimensions and special operating requirements, such as corrosion protection, sealing, and lubrication.

V. Select reliable and trustworthy slewing bearing suppliers.

Get LTZC Bearing Selection Technical Support

View LTZC bearing selection guide

Who manufactures slewing bearings?

LTZC is one of the leading slewing bearing manufacturers and suppliers in China, with over 20 years of experience in bearing research, development, and manufacturing. We specialize in manufacturing standard slewing bearing and non-standard slewing bearings, with product precision ranging from P0 to P5 grades and sizes covering large-diameter slewing bearings from 200mm to 12000mm. Our products are certified with ABS, BV, ISO9001, and ISO 14001 standards. We offer fast response times and delivery within 15-30 days. Our products have been exported to countries such as Italy, Germany, Canada, South Korea, and Japan, making us a trusted global partner for slewing bearings.