Slewing Drives

- Home

- Products

- Slewing Drives

Slewing Drives

LTZC is a leading slewing drive manufacturer specializing in high-precision and high-reliability rotary motion solutions. Our slew drive systems integrate a hardened slewing bearing, optimized gear transmission, and a reinforced housing to deliver stable torque output, long service life, and exceptional environmental resistance. With advanced engineering, strict quality control, and CNC-based fabrication, LTZC provides precision slewing drive products capable of handling axial load, radial load, and overturning moment under demanding industrial conditions.

To meet diverse application requirements, LTZC offers fully customized drive options, including material selection, gear type, sealing level, mounting interfaces, and motor configurations. Our slewing drives are widely used in solar tracking systems, construction machinery, lifting equipment, automation platforms, and heavy-duty industrial equipment, ensuring consistent performance and long-term operational stability.

Dual-Axis Slewing Drive

LTZC provide slewing drive, a dual-axis slewing drive is a precision slewing device that integrates

Learn More Get a Quote

Vertical Type Slewing Drive

The LTZC slewing drive offers precision levels ranging from P0 to P4, enabling precise speed control

Learn More Get a Quote

Solar Tracking Slewing Drive

LTZC is a professional slewing drive manufacturer offering high-quality slew drives

Learn More Get a Quote

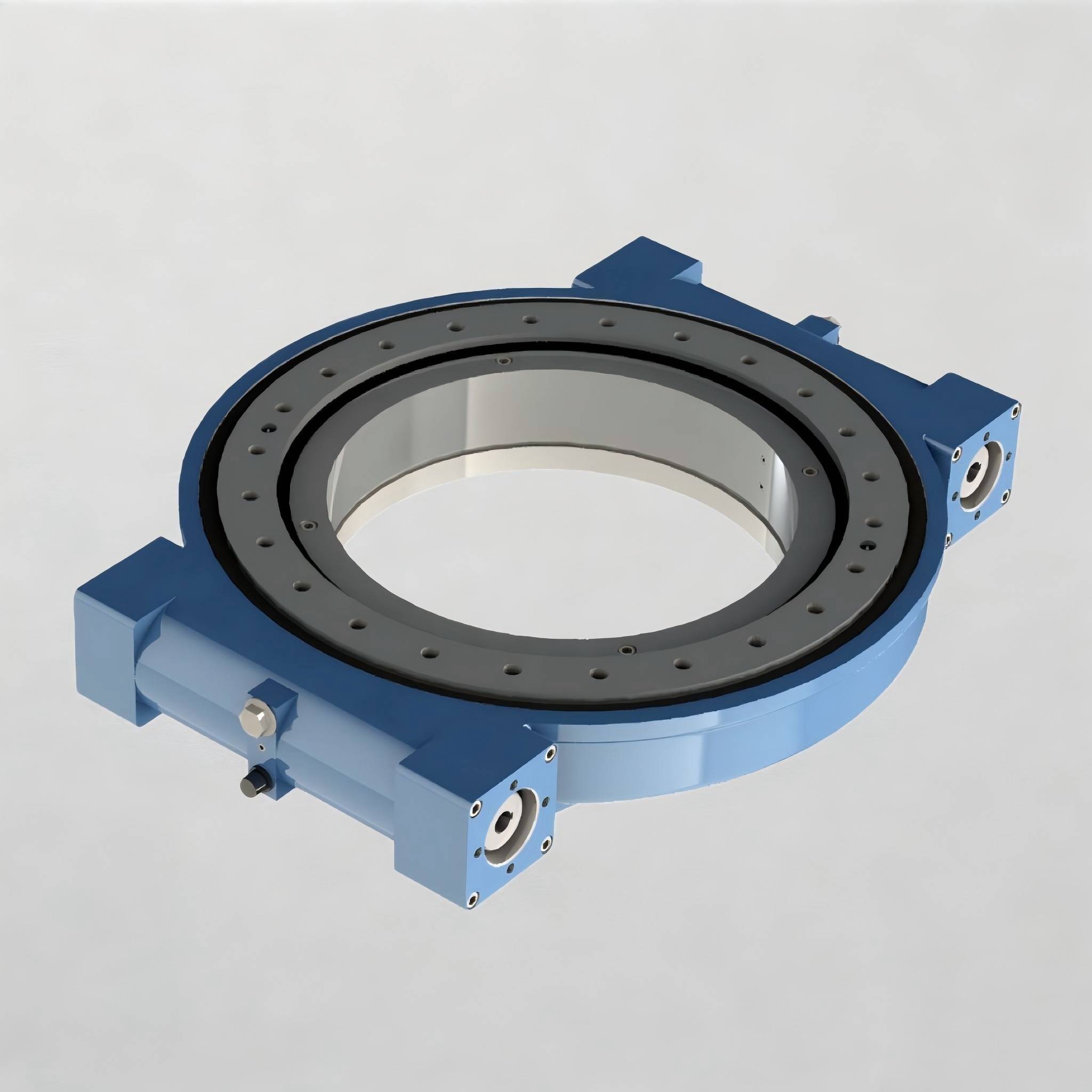

Open Housing Slewing Drive

LTZC provide slewing drive, the open housing slewing drive is a high-precision drive

Learn More Get a Quote

Enclosed Housing Slewing Drive

Enclosed housing slewing drive with high-strength, precision slewing bearing and gear system for

Learn More Get a Quote

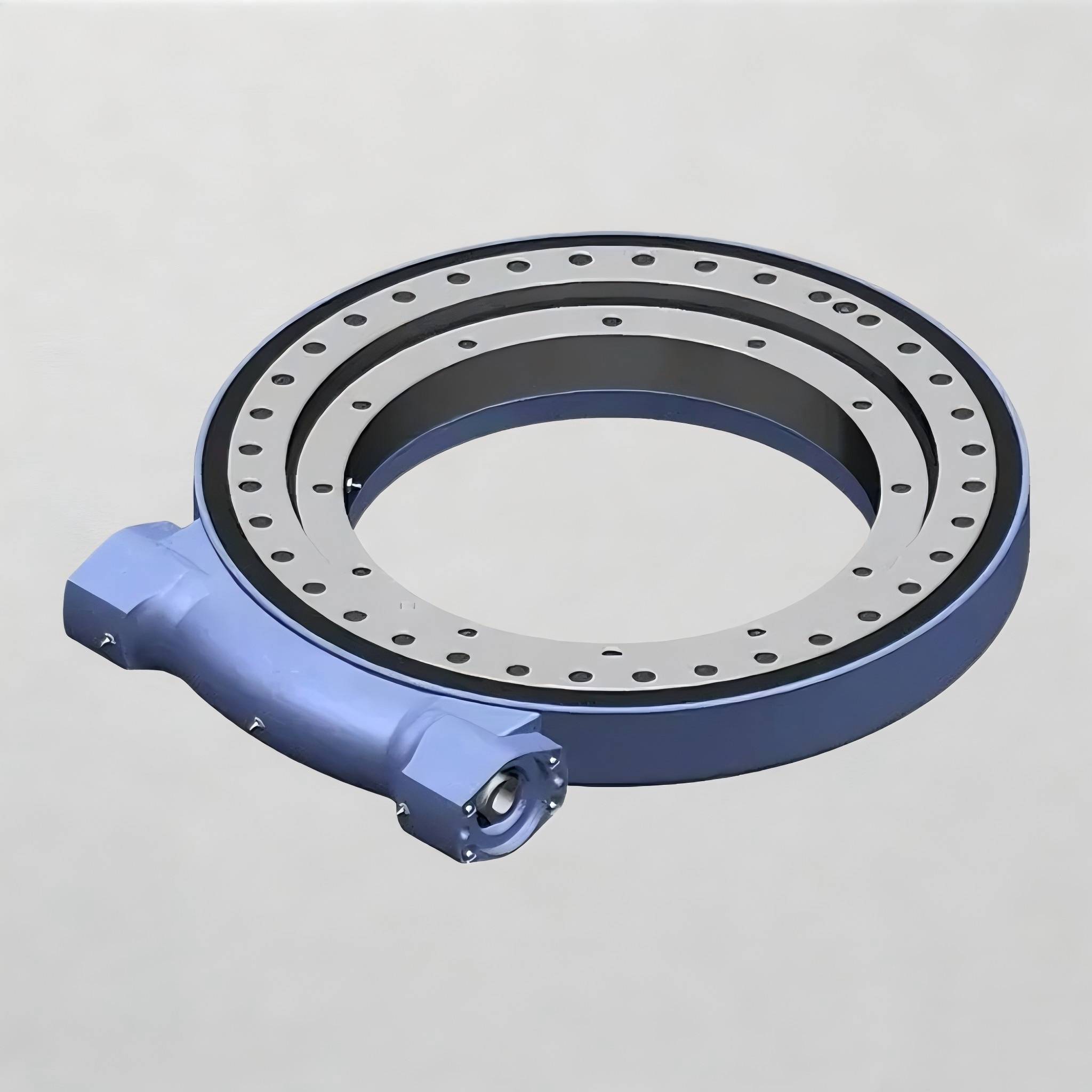

Worm Gear Slewing Drive

The worm gear rotary drive is dustproof and waterproof, making it suitable for long-term

Learn More Get a Quote

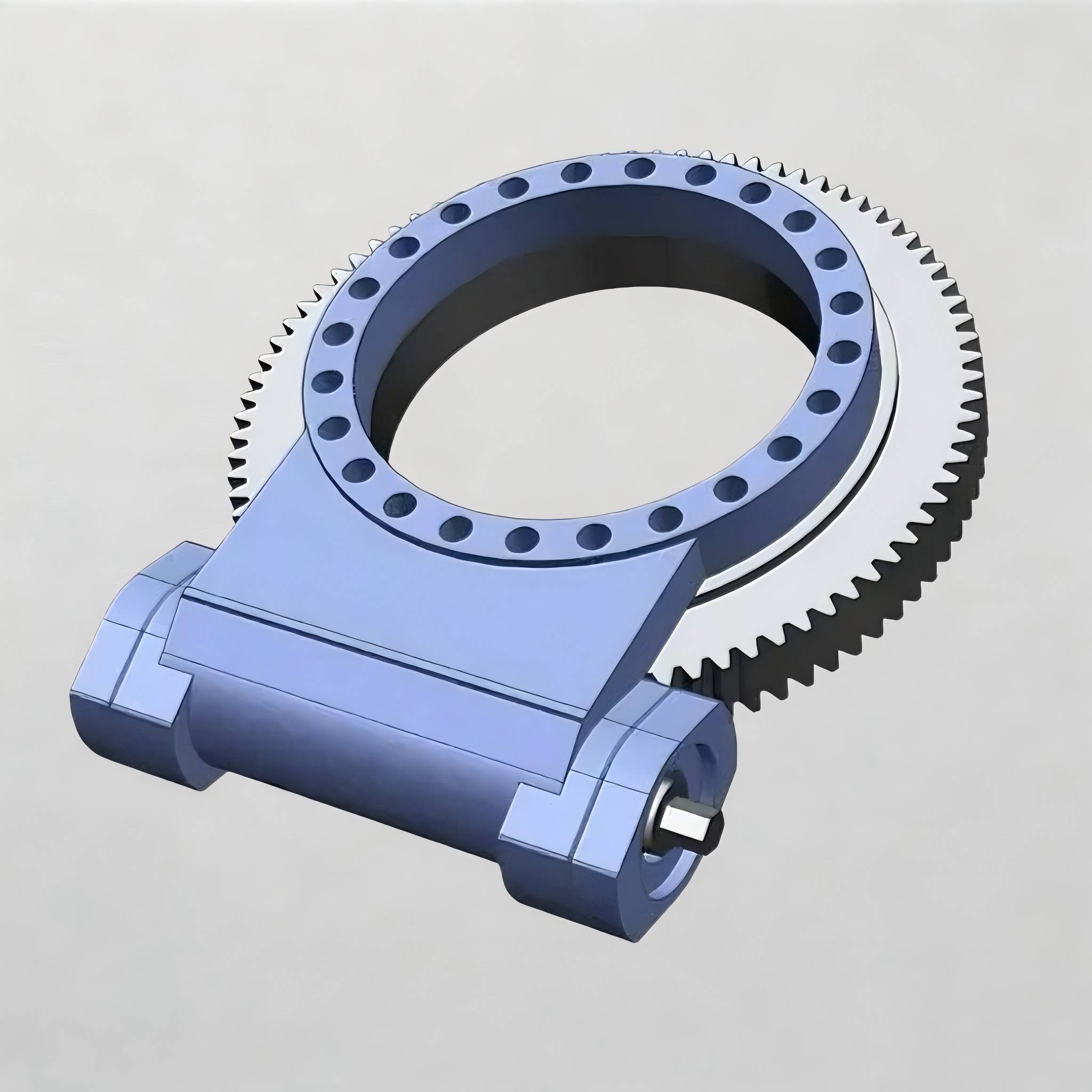

Gear Type Slewing Drive

The gear-type slewing drive integrates a slew gear and slewing bearing, enabling heavy-duty equipmen

Learn More Get a Quote

Customized Slewing Drive

Custom slewing drive engineered for precise rotation, high load capacity, and reliable

Learn More Get a QuoteLTZC slewing drive

High Torque Output Capacity: A single slewing drive can output torque ranging from 3,000 to 150,000 N·m, meeting the heavy-duty slewing requirements of hoisting, wind power, and ports.

High Transmission Efficiency Design: Utilizing a high-precision worm gear/gear transmission system, the transmission efficiency reaches 85%–92%, significantly reducing energy consumption.

High-Precision Slewing Control: Slewing positioning accuracy ≤ 0.1°, repeatability ≤ 0.05°, achieving smooth and precise slewing.

High-Precision Slewing Bearing: Built-in LTZC independently developed slewing bearingwith a raceway surface hardness of HRC58–62 and a load capacity of 500–3000 kN.

Multiple Slewing Drive Types: LTZC slewing drives are available in various design structures, including an overall enclosed design with IP66/IP67 protection ratings, effectively preventing dust, water, and sediment intrusion. Open slewing drives and vertical slewing drives are also available.

Superior Impact Resistance:Optimized tooth surface contact and preload structure adapt to frequent start-stop and impact load conditions.

Multiple Model Customization Capabilities: Supports in-depth customization of axial load, radial load, overturning moment, and mounting interface. It can also replace internationally renowned brand rotary drives, perfectly matching customer equipment structures. If specific data is unclear, LTZC can send professional technicians to conduct on-site measurements and provide CAD drawings.

Stringent Quality Certification System: Certified by ISO 9001/14001/45001, CCS, BV, ABS, and other international certifications.

Wide Application Areas: Suitable for heavy-duty rotating equipment such as solar trackers, wind power systems, cranes, aerial platforms, and port machinery.

What is a slewing drive?

A slewing drive is an integrated heavy-duty rotary transmission component that combines a slewing bearing, a geared motor, and a gear set. With the slewing bearing as the core load-bearing foundation, it uses a motor to drive gear meshing to achieve low-speed, heavy-load, and high-precision rotational motion of the equipment's rotating mechanism. It simultaneously performs both load-bearing (radial/axial/tilting loads) and transmission functions, and is an integrated solution that replaces the traditional separate "bearing + reducer + bracket" structure.

This component integrates support and transmission, eliminating complex assembly and significantly improving the rigidity and coaxiality of the rotating mechanism. It is widely used in engineering machinery, port machinery, new energy equipment, and other equipment requiring heavy-duty rotation.