Gear Parts

- Home

- Products

- Gear Parts

Gear Parts

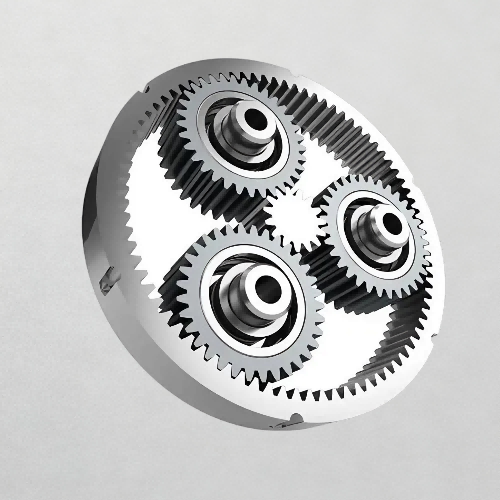

LTZC gears are available in multiple profiles—spur, helical, bevel, and customized designs—delivering efficient power transmission and consistent torque output. LTZC gear rings feature high structural rigidity and excellent meshing accuracy, making them ideal for slewing drives, large slewing mechanisms, construction machinery, and heavy equipment. The gear shafts, manufactured through integrated machining and precision grinding, provide superior concentricity, torsional strength, and durability for high-speed and high-precision transmission systems.

By combining material expertise, optimized heat-treatment technology, and comprehensive quality control, LTZC delivers gear components that meet international transmission standards and support long-term reliability. LTZC gear parts are widely used in slewing drives, heavy machinery, automation systems, mining equipment, energy systems, and high-precision industrial machinery.

Get a Quote

Gear shaft

LTZC bearings provides high-precision gear shafts to ensure stable equipment operation.

Learn More Get a Quote

Gear

LTZC offers a variety of high-precision gears ,gear type including spur gears, helical gears, straig

Learn More Get a Quote

Gear Ring

LTZC bearings offer internal gear rings, external gear rings, and gearless rings, as well as precisi

Learn More Get a QuoteLTZC precision gear parts

LTZC gears, gear shafts, and gear rings are made of special high-strength alloy steel and undergo precision carburizing, quenching, and multi-stage heat treatment processes. The gear surface hardness consistentlyreaches HRC 58–62, and the gear profile accuracy reaches DIN 5–6 grade, ensuring long-term stable operation under high impact and high load conditions. Relying on LTZC's own large-scale productionplant, the entire process from raw material inspection, forging, CNC machining, heat treatment to precision gear grinding is completed independently by the LTZC team, forming a complete closed-loop manufacturing system that ensures the controllability and consistency of each process. Its products have ultimately passed international certificationssuch as ISO9001, 14001, 45001, CCS, BV, and ABS.

View the quality and certificates.

LTZC has over 20 years of experience in the R&D and manufacturing of large bearings and transmission components, and its products are exported to industrialized countries such as Germany, Canada, Italy, and South Korea. Leveraging its capabilities in ultra-large-size bearing customization and its advantages in fully independent manufacturing, LTZC provides professional solutions for heavy-duty transmission systems that offer high strength, high precision bearing, and long lifespan, continuously empowering the high-end equipment manufacturing sector.

Visiting the LTZC bearing production site Contact LTZC for a quote View LTZC manufacturing capabilities

What is a bearing gear?

Gears are mechanical components that mesh together to transmit power. Through the meshing of two or more gears, they can achieve three core functions: speed regulation, torque change, and direction change. They are the most fundamental and widely used core components in mechanical transmission. Gears are typically used in conjunction with toothed slewing bearings; therefore, some customers require custom gears when ordering custom slewing bearings to achieve high-precision meshing, efficient operation, and stable output. Simply put, the core function of gears is to accurately transmit rotational power. By changing the gear ratio of the meshing gears, they enable the conversion between "high speed and low torque" and "low speed and high torque," with high transmission efficiency, precise transmission ratio, and reliable operation. They are the foundation of almost all mechanical power transmission systems.

What are the different types of gear shafts?

A gear shaft is an integrated transmission component that combines a gear and a shaft. The gear teeth are directly machined onto the shaft body, eliminating the need for assembly with connecting elements such as keys or splines. It combines the functions of shaft support/torque transmission and gear meshing, making it a core transmission component in gearboxes, rotary drives, reducers, and construction machinery. It is widely used in applications such as the driving pinion end of gear-type rotary drives and motor output shafts.

1. Slewing Drive Dedicated Gear Shaft / Worm Shaft

Custom-designed for slewing drives, suitable for low-speed, high-torque, and heavy-load slewing conditions. Gear precision reaches ISO 5-6 grade, and the shaft body undergoes carburizing and quenching treatment, ensuring both gear surface wear resistance and shaft rigidity. Available in gear-type slewing drive pinion shafts and worm gear-type slewing drive worm shafts.

Core applications: LTZC full series slewing drives, slewing mechanisms of construction machinery such as truck cranes, mobile cranes, and rotary drilling rigs.

2. Gearbox Gear Shaft

Custom-designed for gearboxes, suitable for multi-stage reduction and high-speed input conditions, with high precision and excellent transmission efficiency. Available in high-speed, medium-speed, and low-speed gear shafts, with modulus and number of teeth matched as needed.

3. Transmission Gear Shaft

Custom-designed for construction machinery transmissions, suitable for frequent shifting and high impact load conditions. The shaft body has high toughness and good impact resistance, and is mostly a stepped multi-gear shaft.

4. Precision Equipment Gear Shaft

Custom-designed for automation and precision machine tool equipment, suitable for high-speed, light-load, and high-precision transmission. Gear precision reaches ISO 4-5 grade, resulting in low noise and smooth operation.