Non-standard Bearing Parts

- Home

- Products

- Non-standard Bearing Parts

Non-standard Bearing Parts

LTZC specializes in engineering and manufacturing non-standard bearing components, specifically designed for heavy-duty, high-precision, and customized rotary systems. With advanced machining capabilities, comprehensive material handling processes, and rigorous quality control, LTZC provides tailored components that enhance structural reliability, sealing performance, and overall system stability in harsh industrial environments.

LTZC's product range includes sealing rings that provide dust, moisture, and contamination protection, ensuring stable bearing operation and extended lifespan. LTZC also manufactures high-precision segmented track for large rotary systems. Furthermore, LTZC offers robust support structures to ensure mechanical strength, precise installation, and optimized load distribution for complex bearings and rotary mechanisms. For applications requiring complete rotary solutions, LTZC offers omnidirectional rotary mechanisms that integrate slewing bearings, gear structures, housings, and drive interfaces, providing high torque, 360° rotation, and long-term operational reliability.

Get a Quote

Seal Ring

LTZC Seal Ring is precision-manufactured, offering superior sealing performance and effectively prev

Learn More Get a Quote

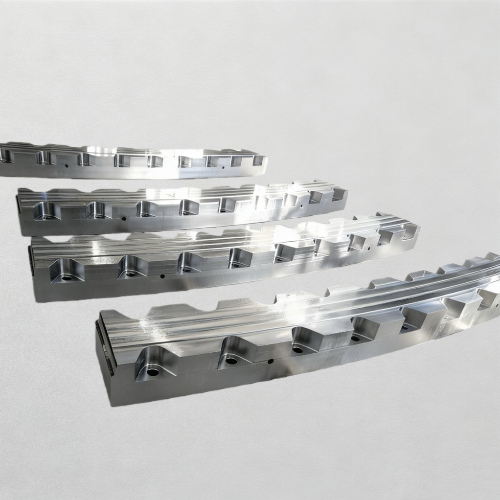

Segmented Track

LTZC Segmented Track is engineered for heavy-duty rotary and linear motion systems

Learn More Get a Quote

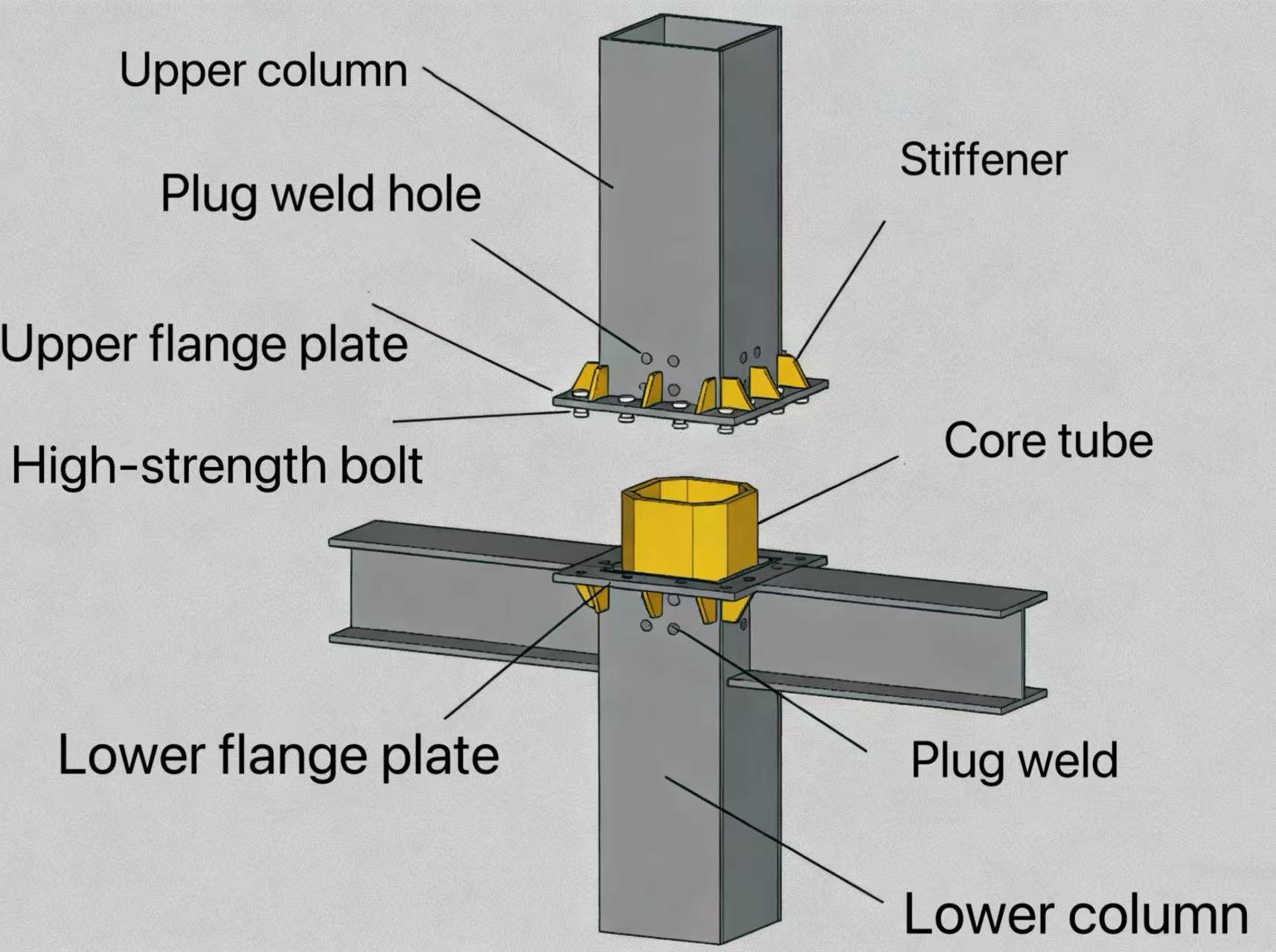

Supporting Structural Parts

LTZC support structures achieve an efficient balance between weight, strength, extending the overall

Learn More Get a Quote

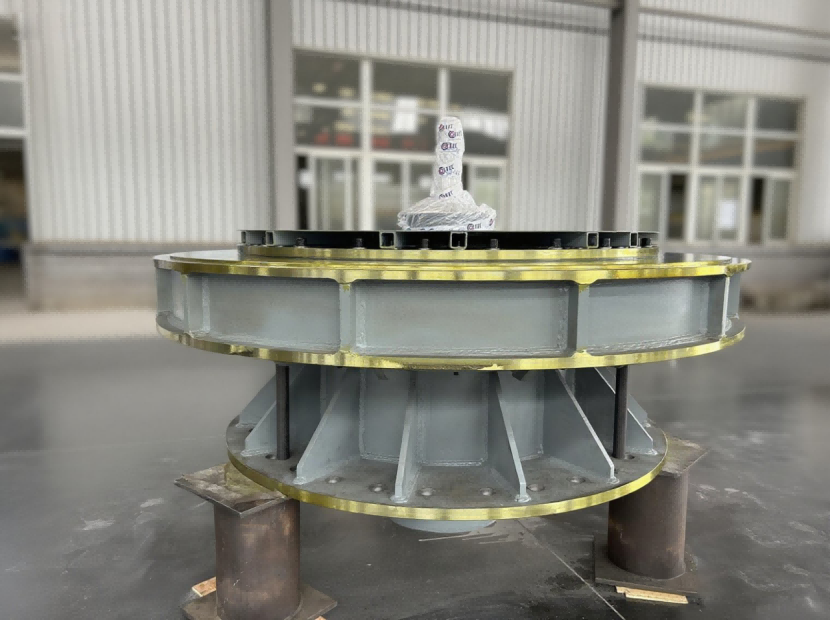

Full Slew Azimuth Mechanism

This full-slew azimuth mechanism adopts a high-strength slewing bearing, precision gear transmis

Learn More Get a QuoteLTZCNon-Standard Bearings solutions

LTZC is a leading slewing bearing manufacturer in China, offering OEM & ODM services. Their customized non-standard bearing solutions focus on large and extra-large precision slewing bearings, covering the entire process from design and manufacturing to delivery. These bearings are suitable for demanding working conditions in various industries, including construction machinery, ports, metallurgy, wind power, and tunnel boring machines. LTZC can independently handle selection, design, manufacturing, and import substitution, with outer diameters ranging from Φ300mm to Φ12000mm and accuracy grades from P0 to P4, efficiently meeting customers' personalized needs.

1. LTZC provides customized non-standard slewing bearings with sizes ranging from 300mm to 12000mm. Large slewing bearings can also be customized beyond standard dimensions as needed. The slewing bearing structures include various types of four-point contact ball slewing bearings, double-row ball slewing bearings, crossed roller slewing bearings, and three-row roller slewing bearings, with internal teeth, external teeth, no teeth, and split structures.

2. We customize bearings with various performance characteristics, including lubrication, sealing, corrosion resistance, and precision, to meet customers' individual needs.

3. Each bearing undergoes comprehensive testing of over 20 parameters, including radial clearance, rotational accuracy, and tooth profile accuracy, and a complete test report is provided; along with installation guidelines, maintenance manuals, and warranty information.

4. Every standard and non-standard slewing bearing from LTZC complies with relevant standards and holds ABS, BV, ISO9001, and ISO14001 certifications.

5. LTZC bearings are suitable for heavy equipment such as excavators, cranes, port machinery, mining and metallurgical equipment, wind power equipment, and tunnel boring machines.

Contact LTZC for customized bearing solution

Who make non-standard bearing

LTZC brand non-standard bearings are the result of over 20 years of accumulated R&D experience in the bearing industry. We are a professional manufacturing enterprise specializing in the customization of large and extra-large non-standard bearings and slewing bearings in China. As a national high-tech enterprise, we possess an independent high-load bearing engineering technology research center and have mastered the core technologies of non-standard bearings from design, simulation, and processing to testing, without any outsourced processes. Our company also operates Luoyang Tezhong Bearing Import & Export Co., Ltd., which is dedicated to the international trade and overseas export of our branded non-standard bearings. We can quickly respond to customer needs and provide customized professional services, making us a globally trusted bearing supplier.

Production Capacity: We specialize in the customization of large and extra-large non-standard bearings with outer diameters ranging from Φ300mm to Φ12000mm. We can exceed conventional size limitations as needed and produce various structural products, including turntable bearings, rolling mill bearings, and bearings specifically designed for tunnel boring machines and wind power applications. Our products cover P0-P4 precision grades and are suitable for various demanding working conditions such as heavy load, high temperature, corrosion, and dust.

Market and Services: Our products are widely used in engineering machinery, ports, metallurgy, wind power, tunnel boring projects, and other industries, and are exported to more than ten countries and regions, including the United States and Italy. Delivery can be completed within 30-45 days after drawing and order confirmation. We provide quality warranty periods and offer technical services such as installation guidance and after-sales troubleshooting.

Core Advantages: We possess mature reverse engineering capabilities for import substitution, allowing us to accurately reproduce the parameters of imported non-standard bearings and achieve performance upgrades, effectively reducing customer procurement costs and supply chain delivery risks.

China's Leading Slewing Bearing Manufacturer

As a leading slewing bearing manufacturer, LTZC provides customers with one-stop solutions covering customized bearings, bearing seals, segmented raceways, support structures, and slewing systems. Certified by ISO 9001/14001/45001 and international certification systems such as CCS, BV, and ABS, LTZC ensures that every non-standard bearing solution possesses international-level reliability and traceability, fully meeting the needs of global high-end equipment manufacturing.

Contact LTZC for a quote! View LTZC manufacturing plant! Learn more about LTZC!