Amusement Equipment

- Home

- Applications

- Amusement Equipment

The Role of Slewing Bearings in Amusement Equipment

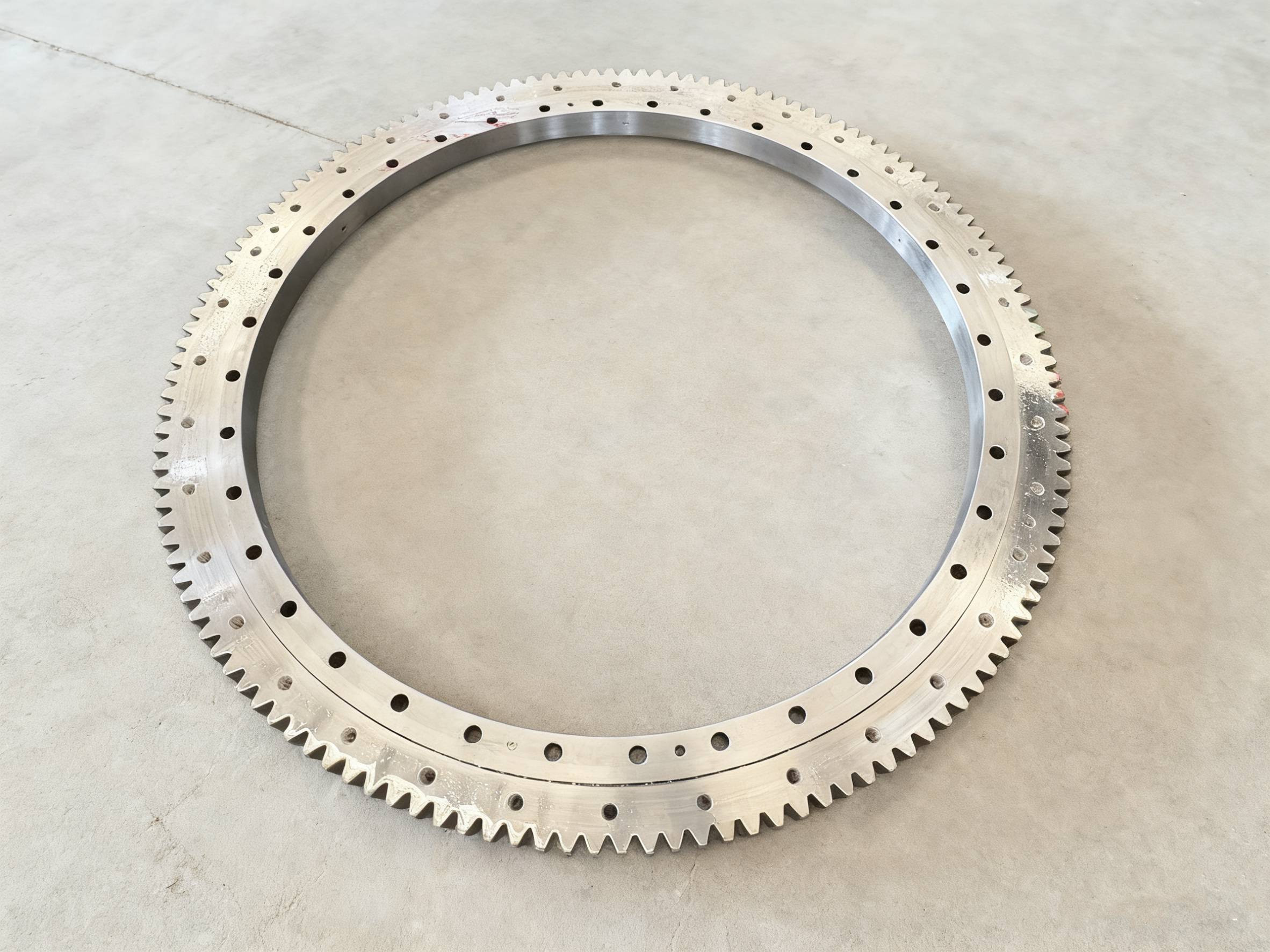

Safety and stability remain core requirements in the modern amusement ride industry. From Ferris wheels and revolving towers to observation turntables and large rotating platforms, every precise rotation relies on the support of high-performance slewing bearings. They not only bear the weight and rotational load of the equipment but also directly impact passenger safety and the equipment's service life.

Ⅰ. Characteristics of Amusement Equipment Bearings

The long-term, repetitive operating environment of amusement equipment requires bearings to meet the following extreme operating conditions:

High loads and long-term continuous operation: Ferris wheels and rotating rides typically rotate smoothly for extended periods, requiring bearings to exhibit high load-bearing capacity and fatigue resistance.

Shock and vibration resistance: The equipment generates strong shock during starting, braking, and rotation, requiring bearings to withstand vibrations and maintain balance.

Corrosion and waterproofing requirements: Outdoor equipment is exposed to moisture, rain, and temperature fluctuations for extended periods, requiring bearings to exhibit excellent sealing and corrosion resistance.

Low maintenance and high reliability: Buyers expect equipment to remain stable over long periods of operation, reducing maintenance frequency and operating costs.

Ⅱ. Key Applications of Slewing Bearings in Amusement Rides

1. Ferris Wheel

As a large rotating device, the Ferris wheel's main support structure relies on large slewing bearings to achieve smooth rotation. LTZC provides ultra-large diameter, heavy-duty slewing bearings, such as triple-row roller slewing bearings, which offer high load capacity and high performance. High-strength alloy steel and advanced processing technology ensure long-term, stable operation.

2. Rotating Towers and Observation Platforms

Rotating towers and observation platforms require extremely high rotational accuracy and quiet operation. Commonly used slewing bearings include double-row ball slewing bearings, crossed roller slewing bearings, and three row roller slewing bearings. LTZC's double-row ball slewing bearings offer high rotational stiffness and low friction, ensuring a smooth rotation experience and enhancing visitor comfort and equipment reliability.

3. Roller Coaster / Motion Simulator

In dynamic simulation and high-speed rotation equipment, bearings must withstand high-frequency load fluctuations and severe shock. LTZC's Cross Roller Slewing Bearing, with its unique cross-arrangement structure, offers exceptional torsional rigidity and high precision, ensuring stable and safe motion systems even at high speeds.

Ⅲ. LTZC's Technical Advantages in Amusement Equipment Bearings

As a professional slewing bearing manufacturer, LTZC provides comprehensive solutions for amusement equipment, from design, manufacturing, to installation. Its products have earned a strong reputation for long-term, stable operation in numerous large Ferris wheels and observation towers both domestically and internationally.

What are the advantages of LTZC bearings?

✅ High load capacity: Optimized raceway structure and material ratios increase load capacity by over 20%;

✅ Excellent sealing protection: A multi-ring design effectively prevents dust and moisture intrusion;

✅ Durable lubrication system: Automatic or scheduled lubrication is supported for extended service life;

✅ Precision manufacturing: Raceway concentricity tolerance is less than 0.01mm, ensuring smooth rotation;

✅ Customized slewing bearings: Dimensions, gear configurations, and mounting methods can be customized to suit the customer's equipment structure and load characteristics.

contact LTZC bearing for customized bearing solutions

★LTZC Amusement Park Bearing Solutions:

Professional Load-Bearing Capacity, Safe and Reliable Operation, Continuous Stable Performance

Leveraging its profound precision manufacturing capabilities,LTZC provides highly reliable, high-load-bearing, and long-life integrated bearing solutions for large-scale amusement park rides such as Ferris wheels, rotating towers, roller coasters, space exploration towers, and self-controlled flying chairs.

① Independent Manufacturing & Ultra-Large Diameter Precision bearing Machining Capabilities

LTZC possesses a complete system from raw materials, forging, heat treatment to precision machining, capable of producing:

Ultra-large diameter bearings ranging from meters to tens of meters

Bearings with load capacities exceeding hundreds of tons

Ultra-high precision machining ensures smooth rotation

② LTZC Provides Extremely High Safety Redundancy Design:

Multiple fatigue life checks

Dual-channel lubrication and sealing redundancy

Heavy-load raceway strengthening treatment

Special gear surface quenching process (for longer gear life)

③ Customized Engineering Support:

Structural design and selection

Ferris wheel center structure scheme

gear precision level optimization

bearing lubrication strategy (grease selection, grease replenishment cycle)

④ Strong Adaptability to Special Environments:

Adaptable to extreme temperatures of -30°C to +80°C

high salt spray environments at sea

LTZC bearings offer integrated measures such as corrosion-resistant coatings, seal upgrades, and surface strengthening.

| Application | LTZC Bearing Solution | Key Advantages |

|---|---|---|

| Ferris Wheel Main Rotation System | Large-diameter three-row roller slewing bearing / segmented raceway system | Extremely high load capacity, excellent stability |

| Rotating Tower / Sky Drop Tower | Large four-point contact ball slewing bearing | Smooth rotation, low noise, reliable performance |

| Self-Control Flying Chair Ride | Medium-size slewing bearing with enhanced sealing | Strong impact resistance, long service life |

| Carousel / Spinning Amusement Rides | Standard or customized roller bearings | High safety, excellent wear resistance |

| Roller Coaster Support & Rotating Components | High-rigidity roller bearings | High structural stability and long-term durability |