Industrial Automation

- Home

- Applications

- Industrial Automation

Robotics and Automation — Precision Slewing Bearings

I. Industrial Automation requires precision bearing

Industrial automation equipment is crucial for improving production efficiency and stability. Automated machinery, robotic systems, packaging lines, and testing equipment require high-precision, long-life, and low-maintenance rotating components. Slewing bearings, with high load capacity, smooth rotation, and compact structure, have become indispensable in industrial automation.

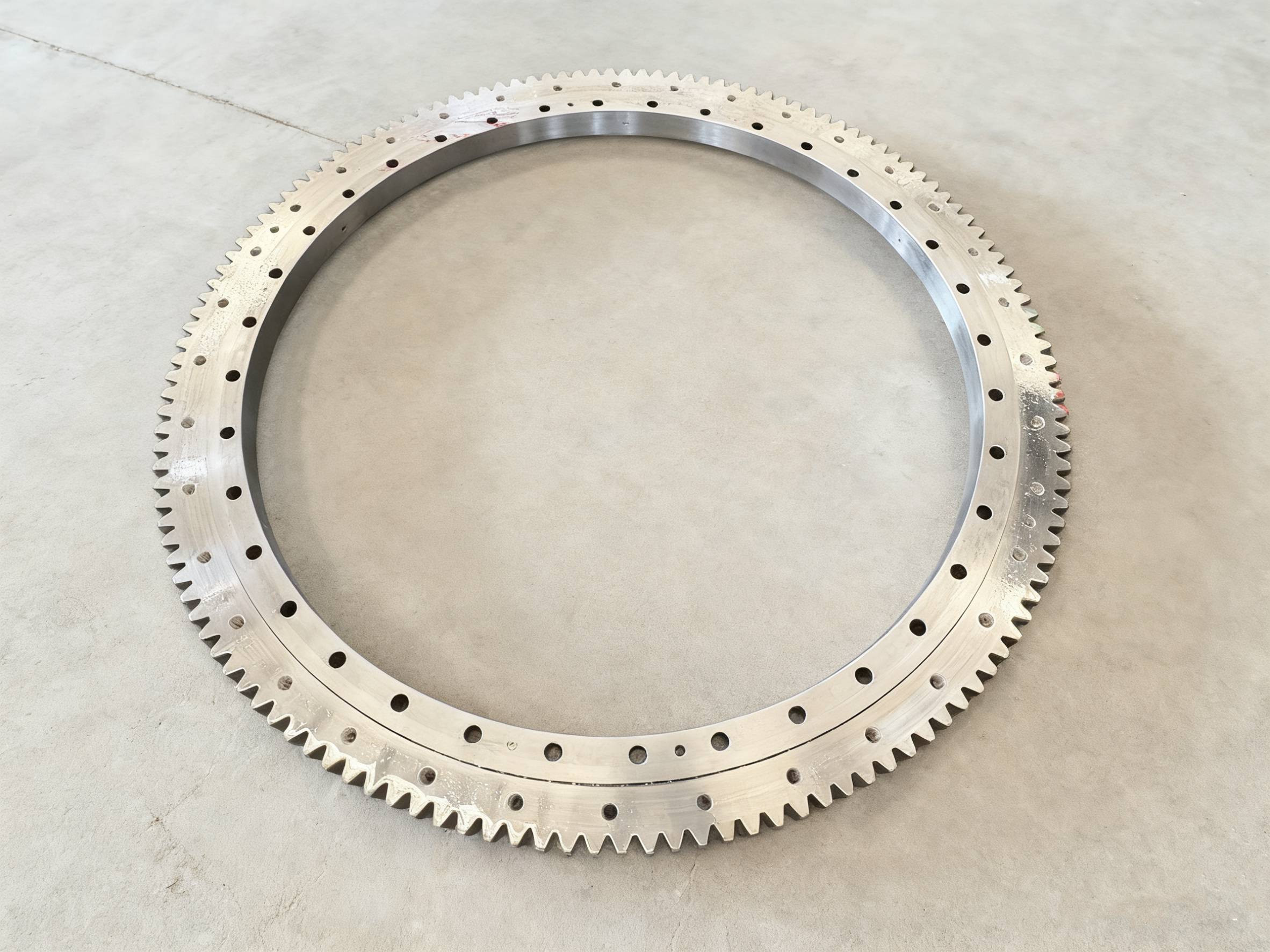

II. What are slewing bearings? — The "rotational core" of industrial automation

Slewing bearings are specialized bearings capable of supporting axial loads, radial loads, and overturning moments simultaneously. They enable large-diameter, low-speed, high-load rotation and are widely used in equipment requiring precise positioning and continuous rotation. In industrial automation, slewing bearings bridge control systems and actuators, ensuring precision, stability, and responsiveness under high-speed and high-frequency dynamic operation.

Types of Slewing Bearings Used in Industrial Automation

| Slewing Bearing Type | Main Features | Load Capacity | Precision Class | Typical Applications |

|---|---|---|---|---|

| Single-row Four-point Contact Ball | Lightweight structure, flexible rotation | Medium | Medium | Packaging, testing platforms |

| Crossed Roller Slewing Bearing | High rigidity, high precision | High | High | Robots, rotary tables |

| Double-row Ball Slewing Bearing | Good stability, strong load-bearing | High | Medium | Assembly, sorting systems |

| Three-row Roller Slewing Bearing | Ultra-high load-bearing, impact-resistant | Extremely High | Medium | Heavy-duty automation equipment |

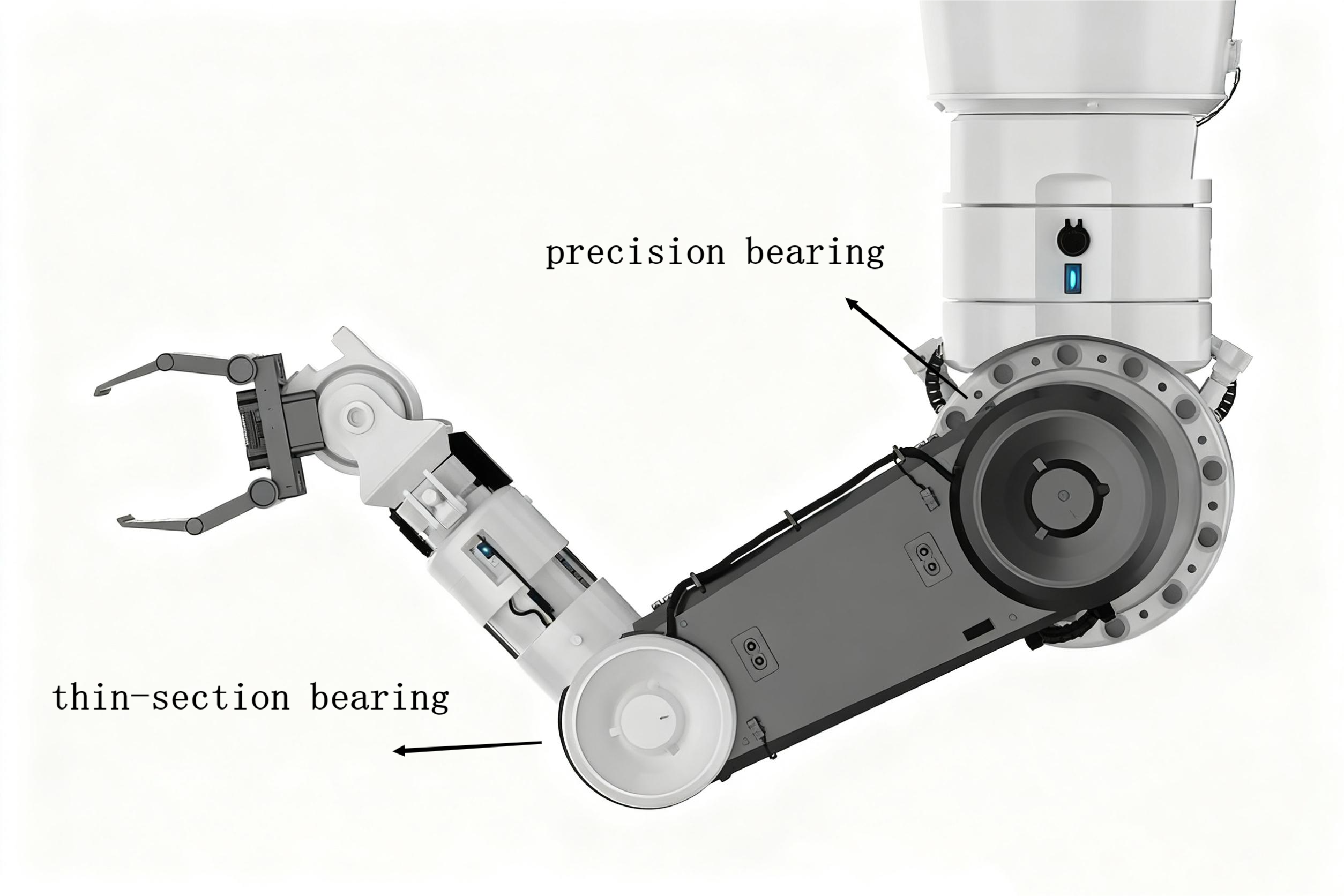

| Thin-section Slewing Bearing | Lightweight, fast response | Medium | High | Small automation equipment |

| Gear Ring | Engageable with motor, easy to control | High | High | Automatic turntables |

| Non-gear Ring | Low noise, smooth operation | Medium | High | Medical and electronic equipment |

III. Applications of Slewing Bearings in Industrial Automation

Industrial Robots and Collaborative Arms

Automated robot slewing bearings are slewing bearings that are connected to the rotating joints of a robot, enabling precise rotation and repeatable positioning. LTZC cross-roller bearings offer high rigidity, near-zero backlash, and angle control accuracy up to ±0.01°, ideal for assembly, welding, and palletizing.Automated Assembly & Handling Systems

Slewing bearings support turntables and robotic arms in feeders, sorting equipment, and conveyors, ensuring smooth movement under load and continuous operation to improve cycle time and reliability.Inspection & Vision Tracking Systems

Precision slewing bearings optimize clearance and preload to minimize vibration and friction, guaranteeing accurate image acquisition and measurement data at high speeds.Packaging & Filling Lines

Slewing bearings distribute loads and reduce friction in filling heads, rotary arms, and rotary tables. LTZC thin-section bearings deliver compact, high-precision solutions for space-constrained packaging equipment.Automated Warehousing & Logistics Systems

Slewing bearings control navigation platforms and turntables in AGVs and warehouse robots, enabling flexible cargo handling and route changes to boost automation efficiency.

IV. Features of LTZC Industrial Automation Slewing Bearings

High-Precision Positioning and Repeatability — Ensures repeatable motion and high efficiency at high frequencies.

High Rigidity and Stable Support — Cross-roller structures and through-hardening treatment resist deformation under load shocks.

Wear-Resistant and Low Maintenance — Sealed dust protection, automatic lubrication channels, and high-temperature grease extend service life and reduce maintenance.

Intelligent Adaptation and Data Monitoring — Integrated sensing for real-time monitoring of temperature, vibration, and wear enables predictive maintenance.

V. LTZC: Slewing Bearing Experts in Industrial Automation

LTZC is a professional slewing bearing manufacturer with over 20 years of precision manufacturing experience. We supply bearings for automation, robotics, machine tools, aerospace, medical equipment, and heavy machinery.

Our Core Advantages

Precision Manufacturing Capabilities: CNC grinding centers and automated assembly & inspection ensure raceway accuracy and concentricity beyond industry standards.

Material and Heat Treatment Control: High-strength alloys (42CrMo, 50Mn) and advanced quenching improve fatigue life.

Customized Design Services: CAD/3D drawings, bearing life calculations, and installation & maintenance instructions tailored to your equipment.

International Standard Certification: Products comply with ISO 9001 for reliable quality and global compatibility.

For precision slewing bearing solutions in robotics and automation, contact LTZC for tailored design, technical consultation, and long-term support.

Click here→ →to see more LTZC bearing certification certificates