Seal Ring

What is the purpose of a seal ring?

Bearing seals primarily serve to isolate the bearing from dust, water mist, and other substances that can affect its stable operation, preventing internal wear, rust, and premature failure. They also retain lubricant, ensuring continuous lubrication, reducing maintenance, and extending bearing life. Bearing seals are mainly divided into contact seals and non-contact seals. Contact seals offer better sealing performance and are suitable for equipment operating at low to medium speeds; non-contact seals are suitable for equipment operating at high speeds.LTZC provides customized bearing sealing services.

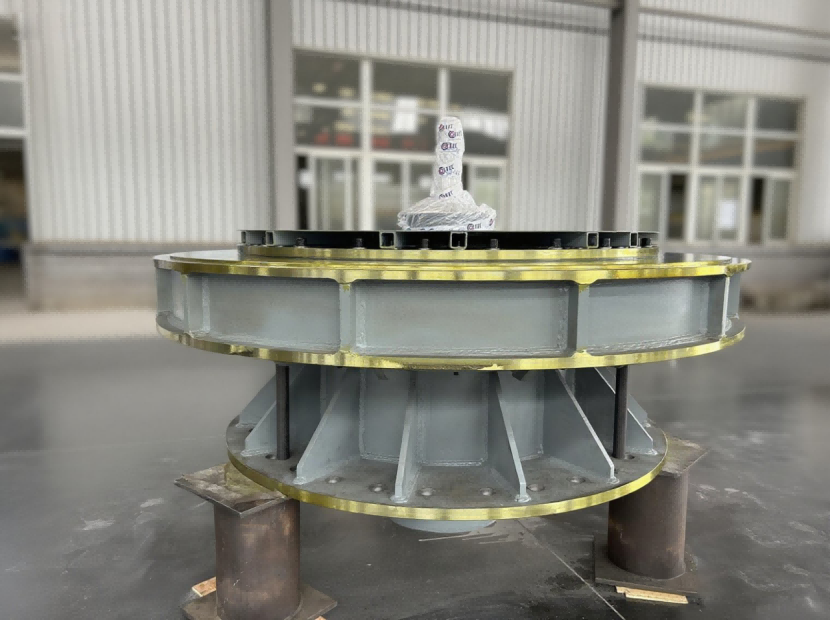

LTZC bearing seal ring

Highly Reliable Sealing Performance

LTZC seals are made of wear-resistant rubber, fluororubber (FKM), or polyurethane, offering excellent oil, water, and dust resistance, extending sealing life by 30%–50% compared to ordinary seals.

High Precision Machining Matching

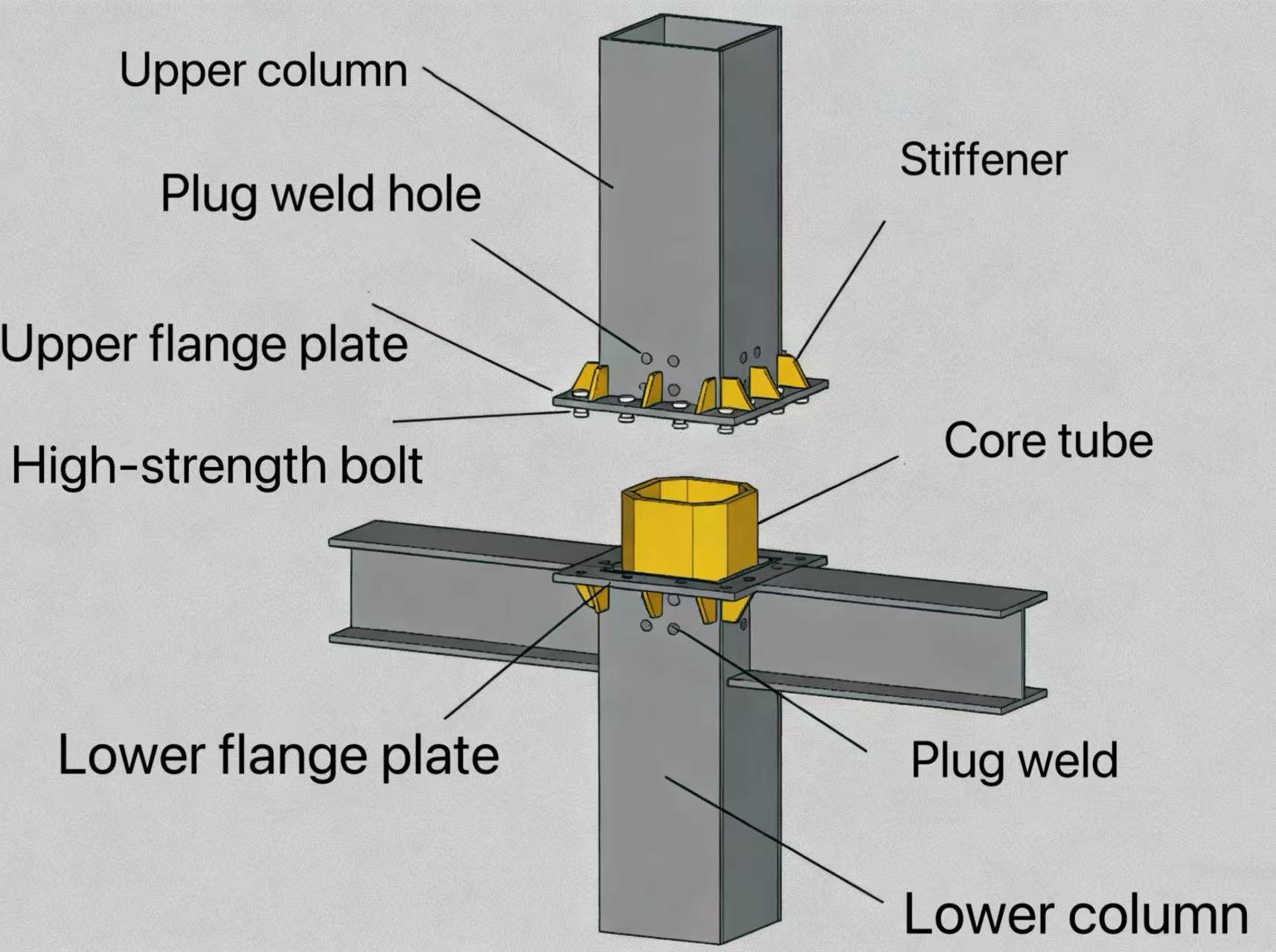

Leveraging LTZC's complete production chain, seals are designed and machined synchronously with bearings, gear rings, and slew drive structures, ensuring a sealing surface clearance consistency of ≤0.05mm, effectively improving overall sealing reliability.

Adaptable to Extreme Conditions

Maintaining stable elasticity and sealing force within a temperature range of -40°C to +180°C, suitable for wind power, marine equipment, construction machinery, and heavy-duty industrial applications.

Lower Friction, Reduced Energy Consumption

LTZC optmizes the sealing structure for slew bearings and slewing drive systems, offering various seal designs to reduce frictional resistance by 10%–15%, helping equipment improve efficiency and reduce heat generation.

Customizable Structures

LTZC offers various sealing structures including V-type, U-type, labyrinth type, and combined types. Materials, hardness, lip structure, and assembly methods can be customized to meet customer equipment requirements.

LTZC Sealing Ring Quality Assurance

LTZC sealing products and complete system kits meet ISO 9001, ISO 14001, and ISO 45001 standards and satisfy marine-grade application requirements such as CCS, BV, and ABS.

LTZC customized seal ring type

| Seal Material | Temperature Range | Main Features | Typical Applications |

|---|

| Nitrile Rubber (NBR) | –40°C ~ +120°C | Good oil resistance, abrasion-resistant, cost-effective | General machinery, motors, automotive bearings |

| Fluororubber (FKM / Viton) | –20°C ~ +200°C | High-temperature resistance, chemical resistance, long service life | Chemical equipment, high-temperature machinery, heavy-duty bearings |

| Silicone Rubber (VMQ) | –60°C ~ +200°C | Excellent low/high-temperature flexibility | Food machinery, medical devices, low-temperature environments |

| PTFE (Polytetrafluoroethylene) | –180°C ~ +260°C | Low friction, corrosion-resistant, ultra-high-temperature capable | High-speed bearings, corrosive environments, clean equipment |

| Polyurethane (PU) | –40°C ~ +90°C | Extremely wear-resistant, high elasticity | Construction machinery, heavy-load equipment, dirty environments |

| Chloroprene Rubber (CR) | –40°C ~ +120°C | Weather-resistant, ozone-resistant, water-resistant | Outdoor equipment, humid environments |

| Metal Seals (Steel + Rubber) | Depends on material | High structural strength, dust-proof, shock-resistant | Heavy-duty bearings, construction machinery |

| Labyrinth Seal | Depends on metal material | Non-contact design, suitable for high-speed rotation | Large slewing bearings, wind turbines |