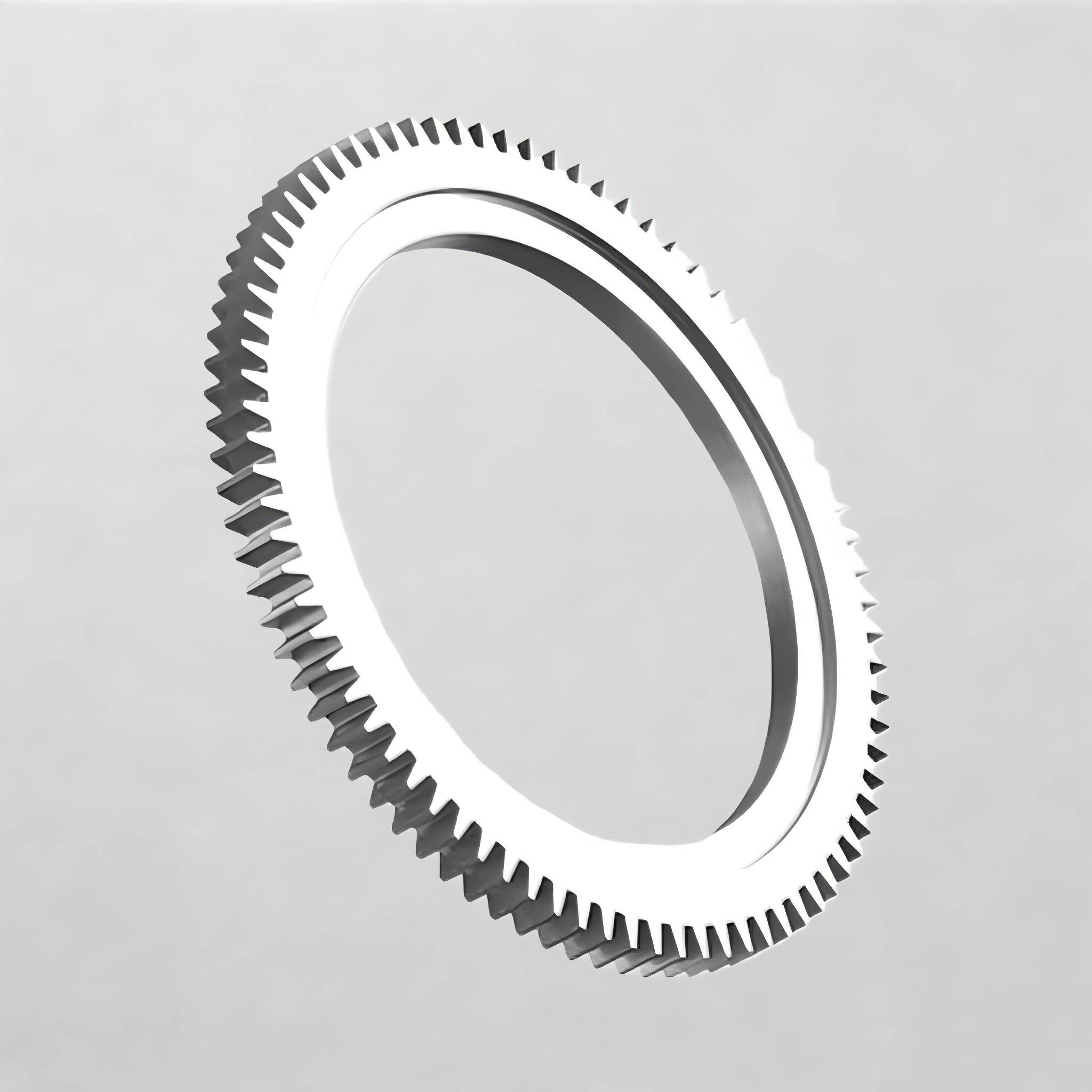

Gear Ring

What is slewing ring gear?

A slewing ring gear is a ring-shaped transmission component, an essential part of slewing drives and slewing bearings, providing both transmission and load-bearing capabilities. It comes in internal and external versions and is typically used in conjunction with slewing bearings. It often meshes with a pinion gear with high precision, converting high speed and low torque into low speed and high torque, driving the slewing bearing/main working device to achieve 360° rotation. The gear profile accuracy and material strength directly determine the transmission efficiency, load capacity, and service life of the slewing drive.

The relationship between the gear ring and the slewing bearing.

Slewing bearing: The core component is the load-bearing part, with built-in raceways and rolling elements. It mainly bears radial, axial, and overturning loads, enabling full-circle rotation of the equipment;

Gear ring: The core component is the transmission part, machined on the inner/outer ring of the slewing bearing, and meshes with the drive gear to achieve power transmission;

Integrated design: In the slewing drive device, the gear ring is not an independent component, but is forged integrally with the inner/outer ring of the slewing bearing, forming a gear ring type slewing bearing. This design meets both load-bearing requirements and transmission functions, and is the core of the modular and compact design of the slewing drive module.

How to Maintain the gear ring?

Lubrication and Protection: The gear teeth require continuous application of extreme-pressure lithium-based grease (general purpose) / synthetic grease (high temperature/salt spray/low temperature). Apply a full grease treatment before sea transport, and replenish grease every 200-500 working hours at overseas construction sites to prevent dry friction and resulting gear tooth wear;

Impurity Removal: Promptly clean sand, dust, and metal shavings from the gear teeth to prevent hard impurities from entering the meshing surface, causing scratches and pitting;

Meshing Clearance Inspection: Check the meshing clearance between the slewing ring gear and the pinion/worm gear every 1000 working hours. Adjust the clearance if it is too large to prevent uneven wear; too small a clearance can lead to overheating and jamming;

Corrosion Protection: For sea transport/coastal conditions, steel slewing rings should be galvanized and coated with anti-rust paint, and copper slewing rings should be passivated to prevent salt spray corrosion;

Overload Protection: Avoid overloading the main machine to prevent tooth breakage and chipping of the slewing ring due to excessive impact loads. Overload sensors can be installed on heavy-duty equipment for overload warning.

LTZC Gear ring advantages

High Transmission Efficiency

LTZC gear rings are precision ground, achieving a meshing accuracy of IT7–IT6 and a transmission efficiency of ≥95%, effectively improving operational efficiency.

Powerful Load Capacity

LTZC bearings specialize in producing large-size gear rings, with a maximum size exceeding 1000mm. Their maximum radial force capacity reaches 5000 kN, and axial force reaches 2500 kN, suitable for heavy-load and high-impact conditions.

High-Precision slew

Rotational accuracy can be controlled within ≤0.05 mm/360°, and vibration acceleration ≤ 2 m/s², ensuring stable equipment operation.

LTZC Gear Rings are Wear-Resistant and Durable

The gears are made of 20CrMnTi alloy steel, tempered and carburized, achieving a tooth surface hardness of HRC58–62 and a service life exceeding 50,000 hours.

Multi-size Gear Ring Design

Supports various structures including internal gear ring, external gear ring , and toothless ring hollow gears, with an outer diameter range of 500 mm–12,000 mm, suitable for wind power, cranes, construction machinery, and other industries.

Customized Gear Ring Solutions

LTZC Bearings has over 20 years of experience in bearing gear ring R&D, professionally providing precision gear rings of various sizes. We can provide customized gear-type slew drives based on equipment load, speed, and working environment, ensuring efficient operation and long service life. Furthermore, all products comply with ISO 9001, 14001, 45001, CCS, BV, and ABS international certifications.

Outer and Inner Ring Gear

| Type | m | z2 | z1 | i | Md max (Nm) | Md nom (Nm) | Mh (Nm) | Co rad (kN) | Co ax (kN) | C rad (kN) | C ax (kN) | Weight (kg) | △P (bar) | Q (L/min) | n (rpm) | Md (Nm) |

|---|

| SG-H-0455 | 8 | 72 | 15 | 4.80 | 26289 | 17209 | 26289 | 508 | 1360 | 236 | 275 | 190 | 195 | 38 | 3 | 26289 |

| SG-H-0555 | 8 | 87 | 15 | 5.80 | 31036 | 20510 | 31036 | 619 | 1658 | 253 | 296 | 215 | 195 | 45 | 3 | 31036 |

| SG-H-0655 | 8 | 99 | 15 | 6.60 | 35783 | 23795 | 35783 | 731 | 1957 | 269 | 314 | 245 | 195 | 52 | 3 | 35783 |

| SG-H-0755 | 8 | 111 | 15 | 7.40 | 40165 | 26793 | 40165 | 843 | 2257 | 284 | 331 | 265 | 195 | 57 | 3 | 40165 |

| SG-H-0855 | 8 | 123 | 15 | 8.20 | 44821 | 31111 | 44821 | 954 | 2556 | 299 | 349 | 295 | 195 | 64 | 3 | 44821 |

| SG-H-0955 | 8 | 135 | 15 | 9.00 | 49293 | 34524 | 49293 | 1066 | 2855 | 311 | 363 | 320 | 195 | 70 | 3 | 49293 |

| SG-H-1120 | 6 | 215 | 20 | 10.75 | 59000 | 39000 | 59000 | 1053 | 3700 | 355 | 413 | - | - | - | 2 | 59000 |