LTZC Heavy-Duty Slewing Bearings for Shield Machine | Professional Bearing Manufacturer

Against the backdrop of accelerating global urbanization, underground space development has become a crucial component of modern infrastructure construction. As a core component of tunnel boring machines (TBMs), the reliability, stability, and service life of the slewing bearing directly determine the construction safety and engineering efficiency of the entire machine.

As a professional slewing bearing manufacturer, LTZC, with over two decades of experience in the R&D and manufacturing of large-scale precision bearings, continuously provides high-performance, long-life, and highly reliable TBM slewing bearing solutions for global TBM projects, offering critical support for world-class underground engineering construction.

LTZC specializes in the production of heavy-duty bearings.

Since its inception, LTZC has consistently focused on high-end equipment manufacturing, concentrating on the technological research and development of large-diameter bearings, heavy-duty slewing bearings, and high-precision bearings.

In the field of tunnel boring machine (TBM) slewing bearings, the LTZC technical team, based on extensive real-world operating data, has deeply optimized key parameters such as bearing contact angle, rolling element arrangement, and raceway structural reinforcement design, enabling products to maintain stable operation under high impact loads and high off-center load conditions.

Through finite element analysis (FEA) and contact fatigue life simulation, LTZC has established a complete set of design standards applicable to extreme operating conditions of TBMs, providing scientific assurance for the long-term reliability of its products in actual engineering projects.

LTZC Tunnel Boring Machine (TBM) Bearing Solution

TBMs operate in complex environments, facing harsh conditions such as high torque, high axial loads, high slurry pressure, and strong impact vibrations, placing high demands on the performance of their slewing bearings.

LTZC has developed a dedicated structural design solution for TBM applications:

Reinforced raceway structure to improve resistance to plastic deformation

Optimized contact angle design to enhance axial and overturning load capacity

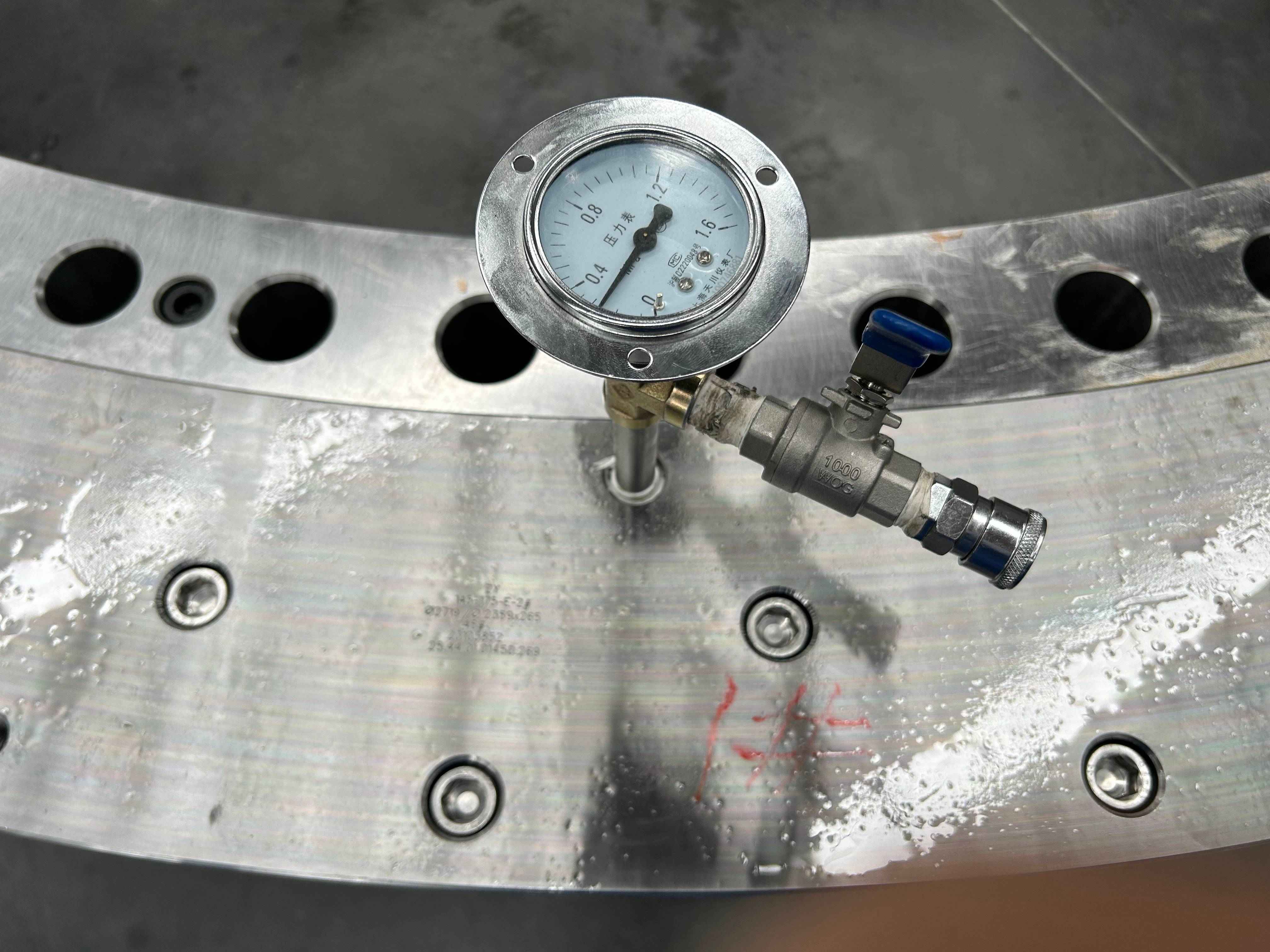

Dedicated sealing system to resist the intrusion of slurry, dust, and corrosive media

High wear-resistant rolling element material system to extend fatigue life

Through synergistic optimization of structure and materials, LTZC TBM slewing bearings maintain stable start-stop performance and rotational accuracy even under long-term continuous operation, significantly reducing equipment failure rates and maintenance costs.

| Design Module | LTZC Technical Solution | Actual Performance |

|---|---|---|

| Raceway Structure | Reinforced raceway + optimized curvature | Reduced contact stress and extended service life |

| Rolling Elements | High load cylindrical rollers / balls | Improved impact resistance |

| Heat Treatment | Deep carburizing and quenching process | Enhanced wear resistance and fatigue strength |

| Cage | High-strength alloy cage | Improved shock resistance and operational stability |

| Sealing System | Multi-stage mud and water protection sealing | Anti-sediment and leakage prevention |

Global Applications, Reliable Bearing Supplier

LTZC's tunnel boring machine (TBM) slewing bearing solutions have been successfully applied in:

Urban subway tunnel projects

Cross-river and cross-sea tunnel projects

Integrated utility tunnel construction

Underground transportation hub projects

Products are exported to Germany, Italy, Canada, South Korea, and other countries, earning the long-term trust of international clients. Through consistent and stable performance in real-world engineering projects, LTZC has established a reliable reputation in the international market, becoming a long-term partner for numerous OEMs and engineering contractors.

LTZC not only provides products but also offers comprehensive technical support services, including:

Preliminary working condition analysis and bearing selection support

Customized bearing design solutions

On-site bearing installation guidance and commissioning support

Full lifecycle maintenance recommendations

Why Choose LTZC Tunnel Boring Machine Slewing Bearings?

1. Professional Manufacturing Capabilities

LTZC boasts over 20 years of experience in the R&D and manufacturing of large-scale precision bearings. With its independent production plant, LTZC ensures that every tunnel boring machine (TBM) slewing bearing achieves internationally leading levels in dimensional accuracy, load-bearing capacity, and long-term reliability.

2. High Load Capacity and High Precision Design

For the complex operating conditions of TBMs, LTZC employs a reinforced raceway design, high-load-bearing rollers, and optimized contact angles to guarantee long-term stable operation of the bearings under high impact, high axial load, and high off-center load conditions. Raceway hardness, surface quality, and roundness control are strictly implemented according to international high-end engineering standards.

3. Customized bearing Solutions

LTZC can provide non-standard customized slewing bearings based on different TBM models and construction conditions, covering different diameters, loads, sealing systems, and installation methods. This ensures a perfect match between the bearing and the TBM system, improving construction efficiency and safety.

contact LTZC for best customized bearing solutions

4. Comprehensive Quality Assurance

Our products strictly adhere to ISO 9001/14001/45001 and international certification standards such as CCS, BV, and ABS, ensuring long-term reliable operation of every product and reducing failure rates and maintenance costs.

View LTZC quality and certifications

5. International Project Verification and Trust

LTZC tunnel boring machine (TBM) slewing bearings have been successfully applied in urban subway, cross-sea tunnel, and integrated utility tunnel projects, and exported to Germany, Italy, Canada, South Korea, and other countries, gaining high recognition from international customers and fully verifying the reliability of LTZC products in high-end underground engineering fields.

Contact LTZC for technology support!

Learn more about LTZC bearings

Summary

Choosing LTZC TBM slewing bearings means choosing high-precision, high-load-bearing, and long-life reliable products, while enjoying fully independent manufacturing, customized design, and global technical support. LTZC is committed to providing long-term reliable core transmission solutions for TBMs and high-end tunnel equipment, making it a trust worthy partner.

Contact LTZC for quote!