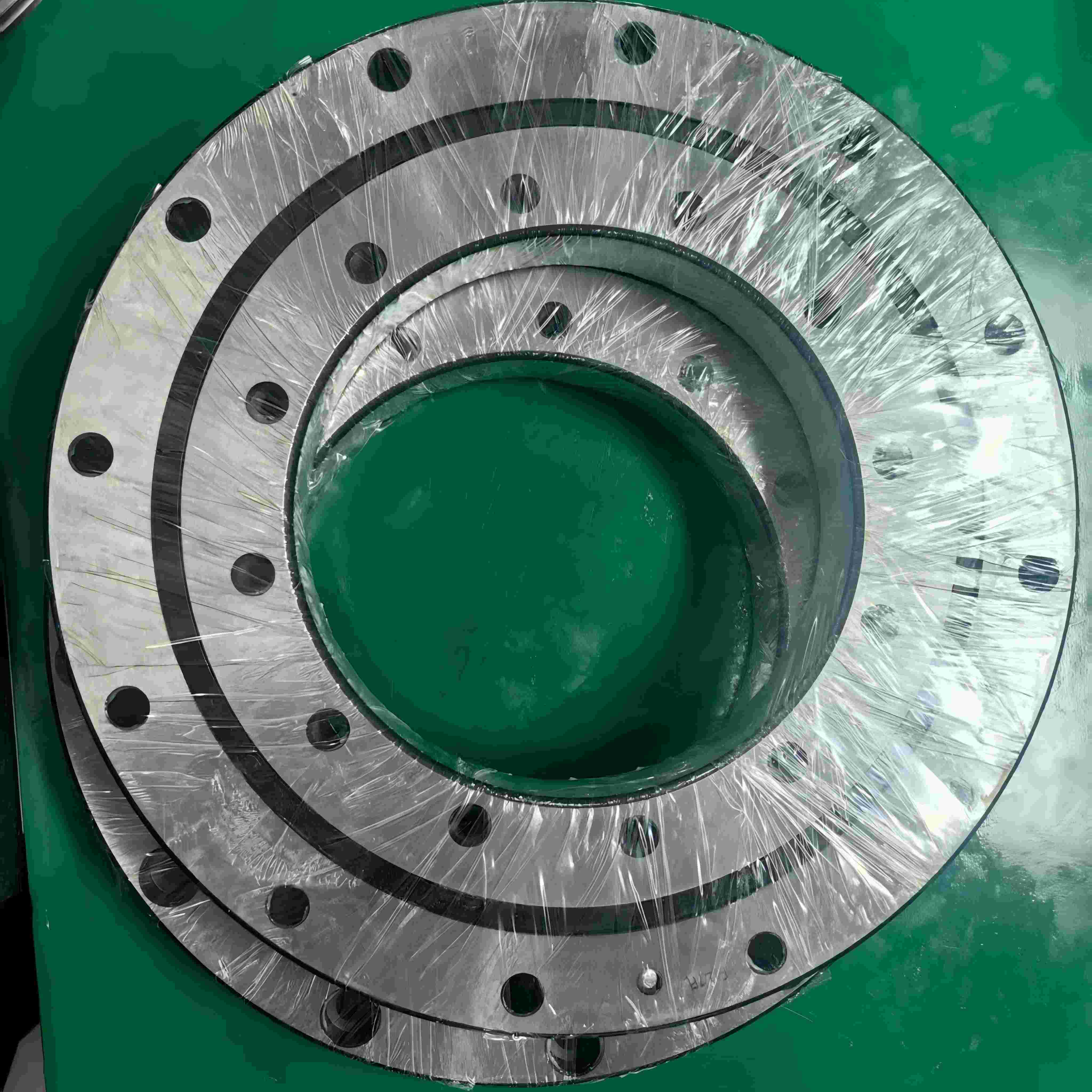

Four-point contact ball bearings

Four-point contact ball bearings features

Lightweight Structure: Thin-section design reduces overall weight and saves installation space.

High Load-bearing Capacity: Withstands complex loads and is suitable for complex working conditions.

High Precision and Stability: Low friction, smooth operation, and low noise, making it suitable for high-speed or precision applications.

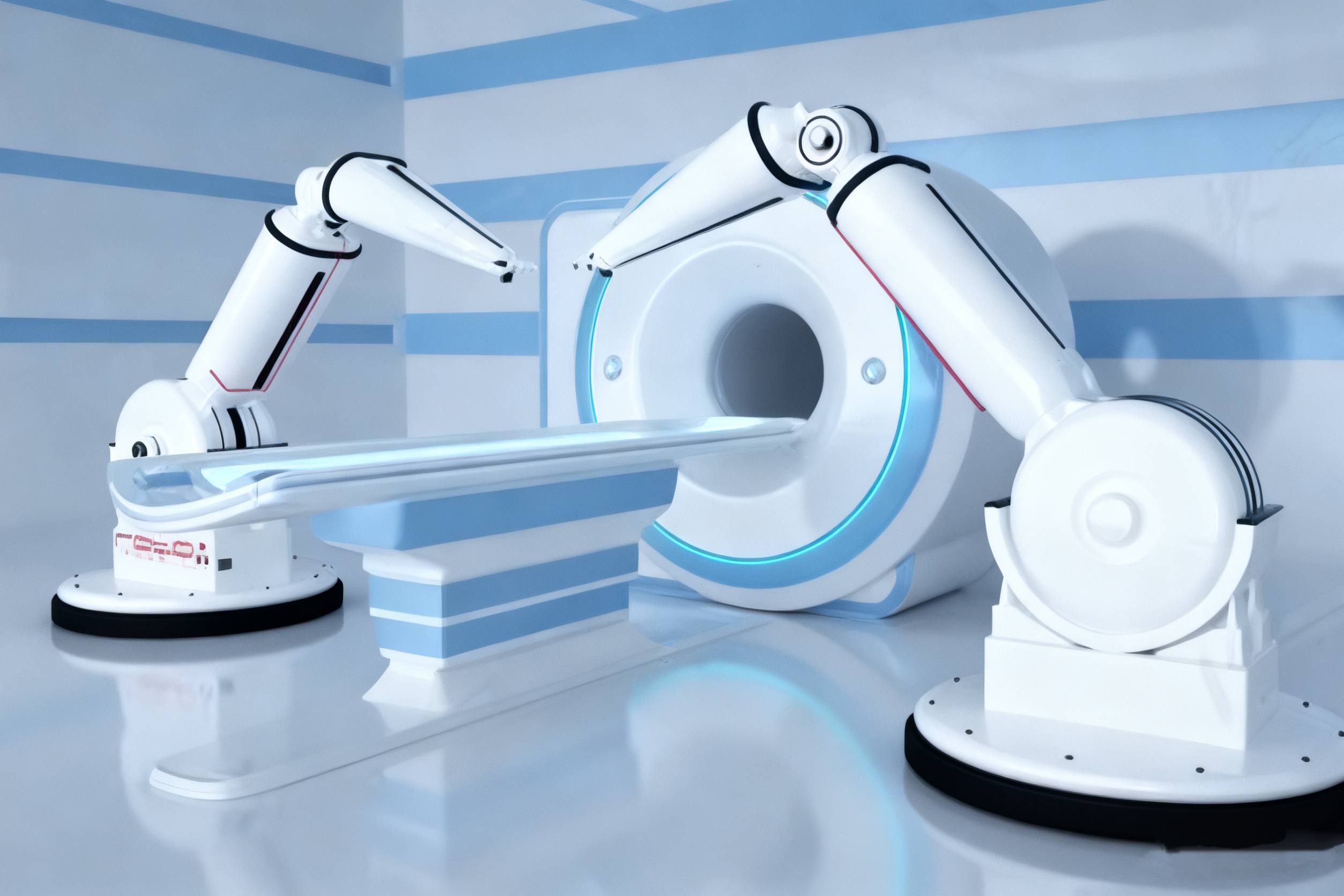

Flexible Application: Suitable for equipment requiring lightweight, compactness, and durability,such as small robotic arms, medical devices.

See the LTZC production site

Four-point contact ball bearings advantages

1. Compact Structure and Flexible Installation

The single-row ball design makes the bearing lightweight, compact, and easy to install. LTZC uses a standard mounting hole distribution and can customize flange structures, gear types, and sealing methods according to customer needs, designing unique bearing solutions.

2. High Rotational Accuracy and Smooth Operation

Through LTZC's precision bearing machining technology (including CNC gear grinding, CNC hardening, and integral raceway machining), the four-point contact ball bearing achieves small clearance and good rotational rigidity, maintaining stable operating accuracy even under medium- and high-speed rotation conditions.Get LTZC technical support

3. LTZC's High-Standard Heat Treatment and Material Guarantee Lifespan

LTZC uses high-grade bearing steels such as 42CrMo/50Mn and employs integral hardening + multi-point temperature-controlled induction hardening technology to ensure uniform raceway hardness and high wear resistance. This gives the four-point contact ball slewing bearing a long lifespan and high reliability.

4. Customizable Gear Structure

LTZC's gear machining capabilities cover modules from 4 to 30, ensuring gear surface hardness and transmission accuracy, making it particularly suitable for engineering machinery, vehicles, and lifting equipment. Get a quote for LTZC bearings

5. Fully Sealed Design for Harsh Conditions

LTZC uses double-lip rubber seals or metal labyrinth seals to enhance dust, mud, and sea fog resistance, and offers pressurized lubrication and high-temperature grease options, adapting to extreme environments. view LTZC seal ring

6. Superior Balance of Cost and Performance

Compared to crossed roller bearings, four-point contact ball bearings are less expensive and easier to maintain, yet still meet most load and accuracy requirements, making them the most economical and stable choice for medium-sized equipment.View LTZC quality and certifications

Four-point contact ball bearings applications

Robotics、Medical equipment、Aerospace、Automation equipment、Lightweight rotary devices

8mm Series - Four Point Contact Ball Bearing

|

Bearing Model

|

Inner Dia d (mm)

|

Outer Dia D (mm)

|

Width B (mm)

|

Dynamic Radial (N)

|

Dynamic Thrust (N)

|

Dynamic Moment (N·m)

|

Static Radial (N)

|

Static Thrust (N)

|

Static Moment (N·m)

|

Weight (kg)

|

|

K02508XP0

|

25

|

41

|

8

|

3246

|

4599

|

40

|

3275

|

7433

|

49

|

0.06

|

|

K05008XP0

|

50

|

66

|

8

|

4511

|

6531

|

98

|

5443

|

13621

|

158

|

0.08

|

|

K06008XP0

|

60

|

76

|

8

|

4962

|

7306

|

127

|

6433

|

16093

|

219

|

0.09

|

|

K07008XP0

|

70

|

86

|

8

|

5384

|

8032

|

158

|

7424

|

18574

|

290

|

0.1

|

|

K08008XP0

|

80

|

96

|

8

|

5796

|

8728

|

191

|

8424

|

21045

|

370

|

0.11

|

|

K09008XP0

|

90

|

106

|

8

|

6188

|

9405

|

228

|

9405

|

23526

|

461

|

0.13

|

|

K10008XP0

|

100

|

116

|

8

|

6570

|

10052

|

266

|

10395

|

25997

|

562

|

0.14

|

|

K11008XP0

|

110

|

126

|

8

|

6933

|

10689

|

307

|

11395

|

28469

|

672

|

0.15

|

|

K12008XP0

|

120

|

136

|

8

|

7286

|

11297

|

350

|

12376

|

30950

|

792

|

0.16

|

|

K13008XP0

|

130

|

146

|

8

|

7630

|

11886

|

395

|

13366

|

33431

|

923

|

0.18

|

|

K14008XP0

|

140

|

156

|

8

|

7963

|

12464

|

442

|

14367

|

35902

|

1063

|

0.19

|

|

K15008XP0

|

150

|

166

|

8

|

8296

|

13033

|

492

|

15347

|

38383

|

1213

|

0.2

|

|

K16008XP0

|

160

|

176

|

8

|

8610

|

13592

|

543

|

16338

|

40855

|

1373

|

0.2

|

|

K17008XP0

|

170

|

186

|

8

|

8924

|

14131

|

596

|

17328

|

43326

|

1543

|

0.2

|

|

K18008XP0

|

180

|

196

|

8

|

9228

|

14661

|

651

|

18319

|

45807

|

1722

|

0.21

|

|

K19008XP0

|

190

|

206

|

8

|

9444

|

15063

|

701

|

19064

|

47660

|

1888

|

0.21

|

|

K20008XP0

|

200

|

216

|

8

|

9728

|

15573

|

759

|

20055

|

50141

|

2086

|

0.22

|

|

K02513XP0

|

25

|

51

|

13

|

6757

|

8522

|

96

|

6825

|

12680

|

96

|

0.096

|

|

K05013XP0

|

50

|

76

|

13

|

8924

|

12023

|

211

|

9012

|

22192

|

280

|

0.2

|

|

K06013XP0

|

60

|

86

|

13

|

9944

|

14082

|

272

|

10778

|

26939

|

393

|

0.23

|

|

K07013XP0

|

70

|

96

|

13

|

10532

|

15171

|

328

|

12043

|

30106

|

500

|

0.26

|

|

K08013XP0

|

80

|

106

|

13

|

11111

|

16210

|

388

|

13317

|

33274

|

619

|

0.28

|

|

K09013XP0

|

90

|

116

|

13

|

12003

|

17730

|

464

|

15210

|

38030

|

784

|

0.31

|

|

K10013XP0

|

100

|

126

|

13

|

12543

|

18691

|

532

|

16485

|

41198

|

931

|

0.34

|

|

K11013XP0

|

110

|

136

|

13

|

13376

|

20104

|

617

|

18387

|

45954

|

1131

|

0.37

|

|

K12013XP0

|

120

|

146

|

13

|

13876

|

21025

|

693

|

19672

|

49131

|

1307

|

0.4

|

|

K13013XP0

|

130

|

156

|

13

|

14377

|

21918

|

771

|

20918

|

52299

|

1496

|

0.43

|

|

K14013XP0

|

140

|

166

|

13

|

15141

|

23222

|

869

|

22820

|

57045

|

1746

|

0.46

|

|

K15013XP0

|

150

|

176

|

13

|

15612

|

24075

|

954

|

24085

|

60223

|

1963

|

0.48

|

|

K16013XP0

|

160

|

186

|

13

|

16073

|

24919

|

1043

|

25360

|

63390

|

2193

|

0.51

|

|

K17013XP0

|

170

|

196

|

13

|

16779

|

26145

|

1152

|

27262

|

68146

|

2494

|

0.54

|

|

K18013XP0

|

180

|

206

|

13

|

17220

|

26949

|

1247

|

28528

|

71314

|

2753

|

0.57

|

|

K19013XP0

|

190

|

216

|

13

|

17652

|

27743

|

1344

|

29793

|

74482

|

3024

|

0.6

|

|

K20013XP0

|

200

|

226

|

13

|

18319

|

28910

|

1464

|

31695

|

79238

|

3375

|

0.63

|

|

K25013XP0

|

250

|

276

|

13

|

20780

|

33372

|

2050

|

39305

|

98253

|

5168

|

0.77

|

|

K30013XP0

|

300

|

326

|

13

|

22820

|

37206

|

2680

|

46278

|

115679

|

7242

|

0.91

|

|

K32013XP0

|

320

|

346

|

13

|

23722

|

38893

|

2963

|

49445

|

123613

|

8232

|

0.97

|

|

K34013XP0

|

340

|

366

|

13

|

24595

|

40531

|

3257

|

52613

|

131527

|

9286

|

1.02

|

|

K36013XP0

|

360

|

386

|

13

|

25438

|

42149

|

3560

|

55780

|

139451

|

10403

|

1.08

|