What is a slewing ring on a crane?

In crane operation scenarios, whether it's container handling at port terminals or material lifting at construction sites, the crane's boom can always rotate horizontally with flexibility, precisely delivering heavy objects to the designated location. This crucial movement is made possible by a key component – the slewing bearing. Known as the "rotating joint" of the crane, it connects the fixed parts of the crane (such as the chassis and frame) to the rotating parts (such as the boom and rotating platform), and is the cornerstone for ensuring stable and precise crane operation.

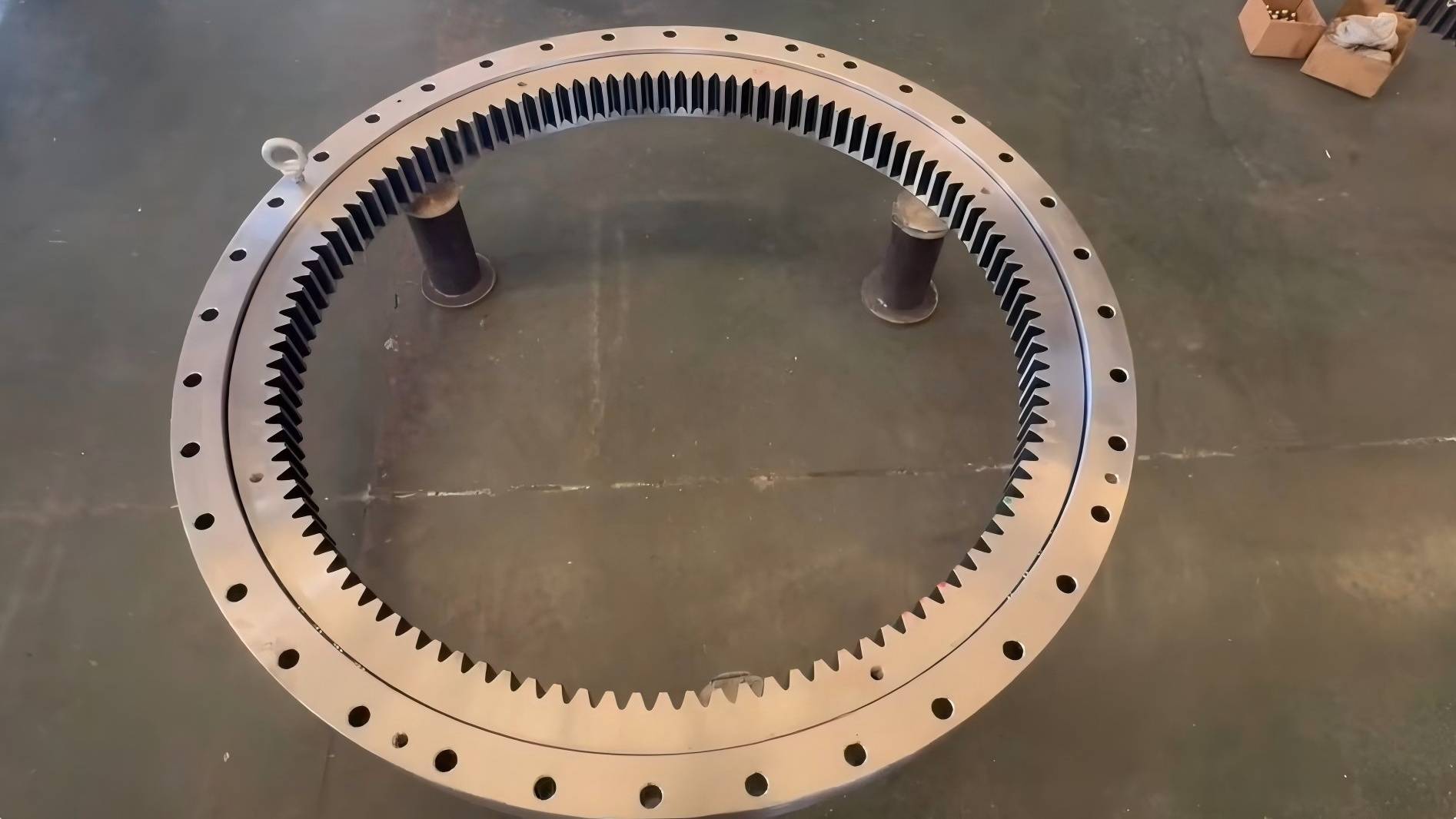

What is a crane slewing bearing?

A crane slewing bearing is a large, precision bearing component capable of simultaneously withstanding axial force, radial force, and overturning moment. The slewing bearing not only bears the load but also facilitates the rotational function of the equipment.

In the slewing mechanism of a crane, the slewing bearing works in conjunction with the driving device (motor, hydraulic motor, etc.) and the transmission device (gearbox, pinion, etc.): the power from the driving device is transmitted through the transmission device to the pinion that meshes with the outer ring (or inner ring) of the slewing bearing, driving the rotating part to rotate relative to the fixed part, ultimately achieving the horizontal movement of the heavy load. Without the stable support and precise guidance of the slewing bearing, the crane's boom would be unable to perform 360-degree rotation.

What are the components of a crane slewing bearing?

1. Inner and Outer Rings: As the main frame of the slewing bearing, they are usually made of high-strength alloy steel, with the surface hardened (hardness up to HRC55-62) to improve wear resistance and fatigue resistance. Both the inner and outer rings have precision raceways to accommodate the rolling elements; some outer or inner rings also have gear rings that mesh with the drive pinion to transmit power.

2. Rolling Elements: Common types include balls, steel balls, and rollers. Depending on the load requirements, the rolling elements can be arranged in single, double, or triple rows. Triple-row roller slewing bearings have a higher load capacity and are suitable for large cranes.

3.Used to separate adjacent rolling elements, preventing them from colliding and rubbing against each other during rotation, ensuring even distribution of the rolling elements and improving rotational stability.

4. Sealing ring: Installed in the gap between the inner and outer rings, its main function is to prevent dust, sand, moisture, and other impurities from entering the raceway, while also preventing internal lubricant leakage. The quality of the sealing performance directly affects the service life of the slewing bearing.

5. Lubrication System: Includes grease nipples, oil passages, etc., used to inject lubricant (mainly grease) into the raceway and rolling elements to reduce friction and wear, and also to provide rust prevention and cooling.

How to maintain crane slewing bearings?

1. Regular lubrication: Regularly inject appropriate grease through the grease nipples to ensure sufficient lubrication of the raceway and rolling elements.

2. Seal inspection and cleaning: Regularly check whether the sealing device is intact. If the seals are found to be damaged or aged, they should be replaced promptly to prevent impurities from entering the sealing gap.

3. Bolt tightening inspection: The connecting bolts between the inner and outer rings and the crane structure are prone to loosening due to vibration. They need to be regularly inspected and tightened to prevent bolt loosening from causing slewing bearing displacement, uneven stress distribution, and subsequent failures.

4. Avoid overloading: Strictly operate within the crane's rated load to avoid overloading or excessive eccentric loading, preventing damage to the slewing bearing due to loads exceeding its design limits.

5. Regular wear inspection: Use professional tools to detect the degree of wear on the raceway and rolling elements, as well as any abnormal noises or vibrations during rotation. If any abnormalities are found, the machine should be stopped for inspection or replacement.

Replace with high-quality LTZC bearings

LTZC Crane Slewing Bearing Solutions

With over 20 years of experience in bearing research and manufacturing, LTZC specializes in slewing bearings for heavy machinery such as cranes, excavators, and tunnel boring machines. We possess extensive design and manufacturing expertise. LTZC bearings have been exported to more than ten countries, including Germany, Canada, and South Korea, consistently receiving positive customer feedback.

LTZC bearings have an independent production factory with strict control over the manufacturing process. Our products are certified to ISO 9001, 14001, 45001, CCS, BV, ABS, and other standards, ensuring that every slewing bearing leaving our factory meets the required standards.

View LTZC Manufacturing Capabilities