Products

- Home

- Products

Products

LTZC is a leading Chinese manufacturer of slewing bearings, specializing in high-precision and heavy-duty slewing bearing solutions for the industrial, construction, and energy sectors. Leveraging advanced machining technology and a comprehensive in-house production system, LTZC can provide customized slewing bearings for various applications, including large-diameter, ultra-heavy-duty, complex-structure, and demanding products.

Our product range encompasses four-point contact ball slewing bearings, crossed roller slewing bearings, three-row roller slewing bearings, gear slewing bearings, precision thin-walled bearings, segmented tracks, sealing rings, and support structures, meeting a wide range of needs from standard to highly customized.

LTZC precision slewing bearings meet P0–P6 accuracy grades and are certified by ISO 9001, 14001, 45001, CCS, BV, ABS, and other standards, ensuring stable and durable performance under continuous, high-intensity, or harsh environments. We support full customization of materials, heat treatment, gears, seals, and structures, providing reliable and efficient solutions for wind power, cranes, excavating equipment, offshore platforms, automation, robotics, mining machinery, and heavy engineering equipment.

Get a Quote

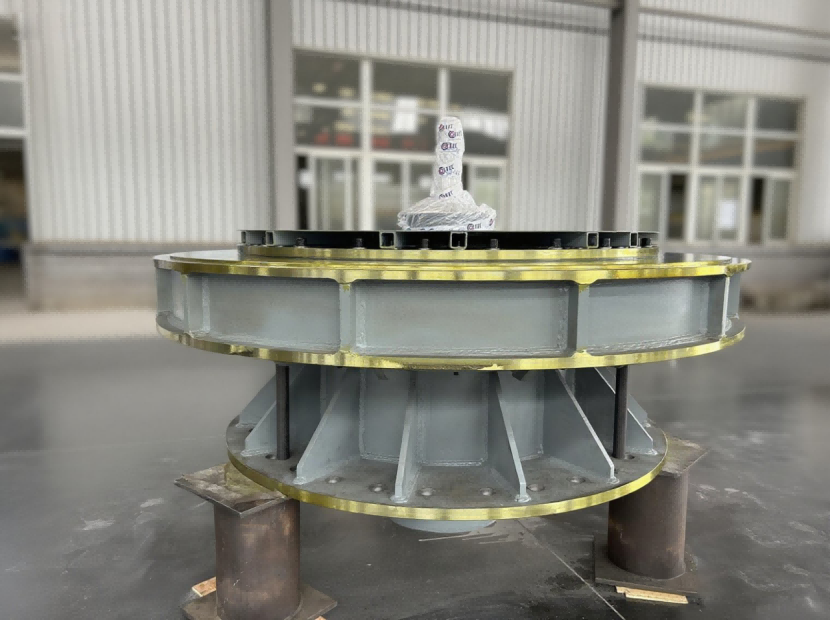

Full Slew Azimuth Mechanism

This full-slew azimuth mechanism adopts a high-strength slewing bearing, precision gear transmis

Learn More Get a Quote

Customized Slewing Drive

Custom slewing drive engineered for precise rotation, high load capacity, and reliable

Learn More Get a QuoteSlew Ring Bearing

Slewing bearings are critical rotating support components capable of withstanding axial forces, radial forces, and overturning moments. They consist of an inner ring, outer ring, rolling elements, and a cage, enabling smooth rotation of equipment under heavy loads. LTZC slewing bearings are characterized by high load capacity, compact structure, and high operational precision, and are widely used in cranes, wind power, excavators, robots, marine engineering equipment, and industrial automation. Full customization is available for gear types, raceway structures, sealing designs, materials, and dimensions.

Slewing Drive

Slewing drive is an integrated slewing system composed of a slewing bearing and a worm gear or gear transmission mechanism, enabling precise and stable angle control and torque output. LTZC slewing drives encompass worm gear drives, gear drives, dual-axis rotary drives, and solar tracking-specific drives, featuring high strength, excellent sealing, and superior protection. Suitable for various applications including solar photovoltaic tracking systems, construction machinery, radar antennas, robot joints, and offshore platforms, they support comprehensive customization of torque, speed ratio, motor interface, and housing structure.

Thin-Section Bearing

Thin-section bearings feature an ultra-thin cross-section design, maintaining high rigidity and high-speed performance while reducing weight and saving space. The LTZC thin-section bearing series includes open, sealed, ball, and roller bearings,four-point contact ball bearings, deep groove ball bearings, angular contact ball bearings suitable for robot joints, medical devices, semiconductor equipment, aerospace instruments, and high-speed rotating platforms. With precision machining and strict tolerance control, LTZC can provide high-precision thin-section bearings from P0 to P6 grades, as well as custom-made non-standard sizes.

Gear Parts

Gears and gear rings are core components for power and torque transmission, enabling precise drive and synchronization of equipment under complex operating conditions. LTZC specializes in producing high-precision gears, gear shafts, gear rings, segmented gear rings, internal gear rings, and external gear rings, with tooth profiles meeting various standards from module 2 to 40. Through CNC hobbing, grinding, and heat treatment processes, LTZC provides high-strength, low-noise, and wear-resistant gear assemblies suitable for slewing bearings, construction machinery, wind power, mining equipment, and automation systems.

Non-Standard Bearing

LTZC possesses comprehensive R&D and manufacturing capabilities, and can provide customized products such as non-standard slewing bearings, large heavy-duty bearings, multi-row roller bearings, and combined bearings according to customer drawings or project requirements. We support special steels, heat treatment, coatings, corrosion protection, and lubrication solutions to ensure reliable operation under high temperature, extreme cold, high vibration, or continuous heavy load conditions.