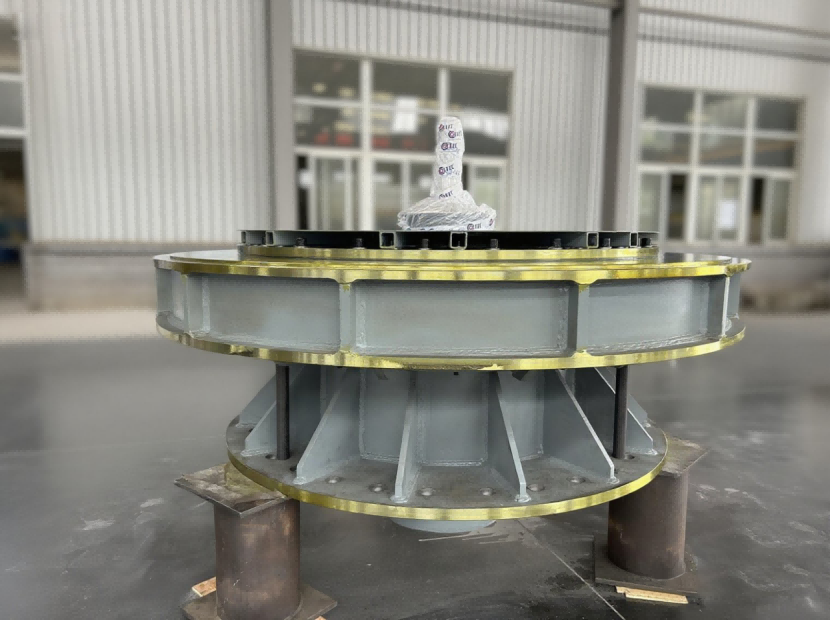

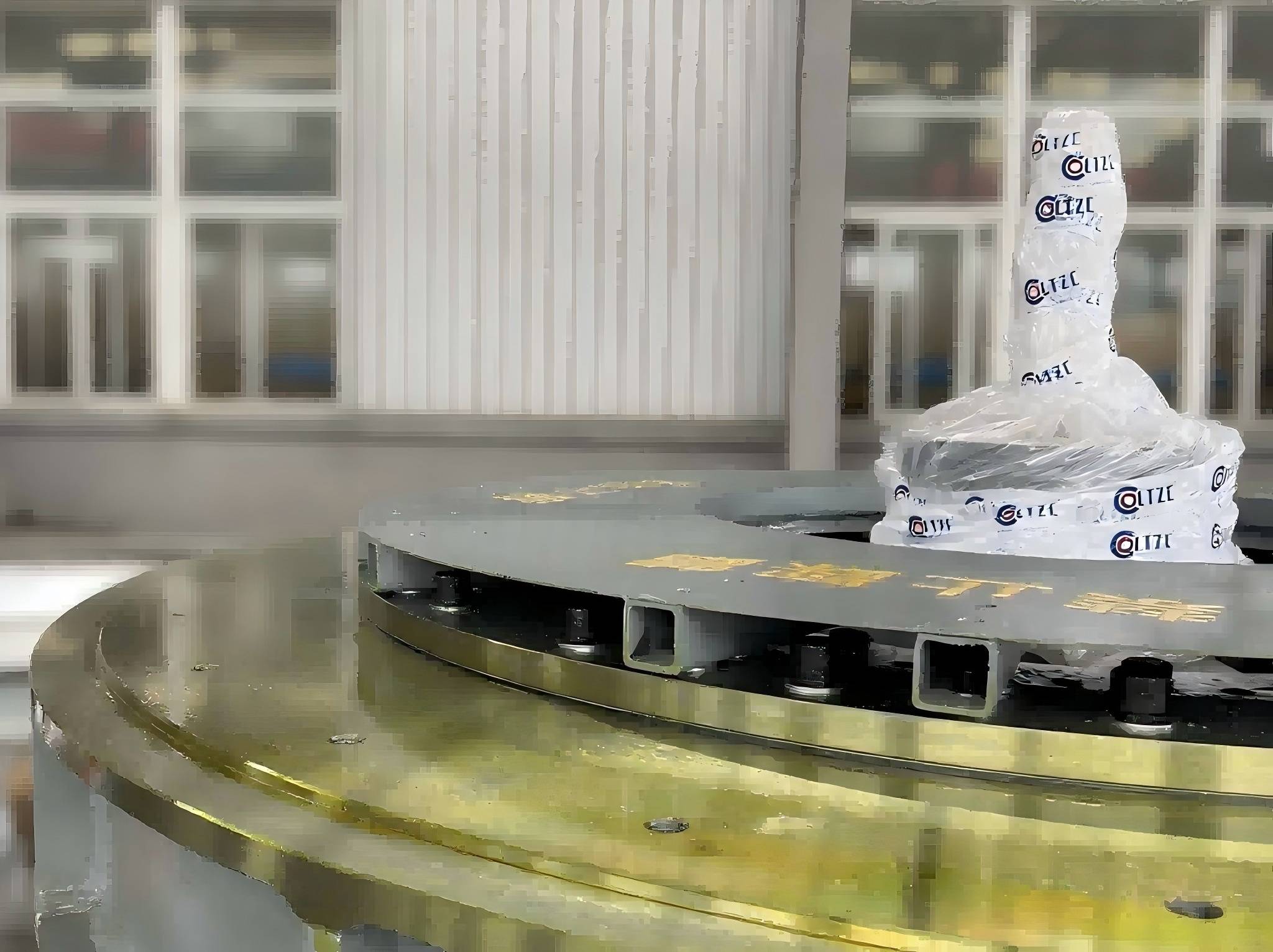

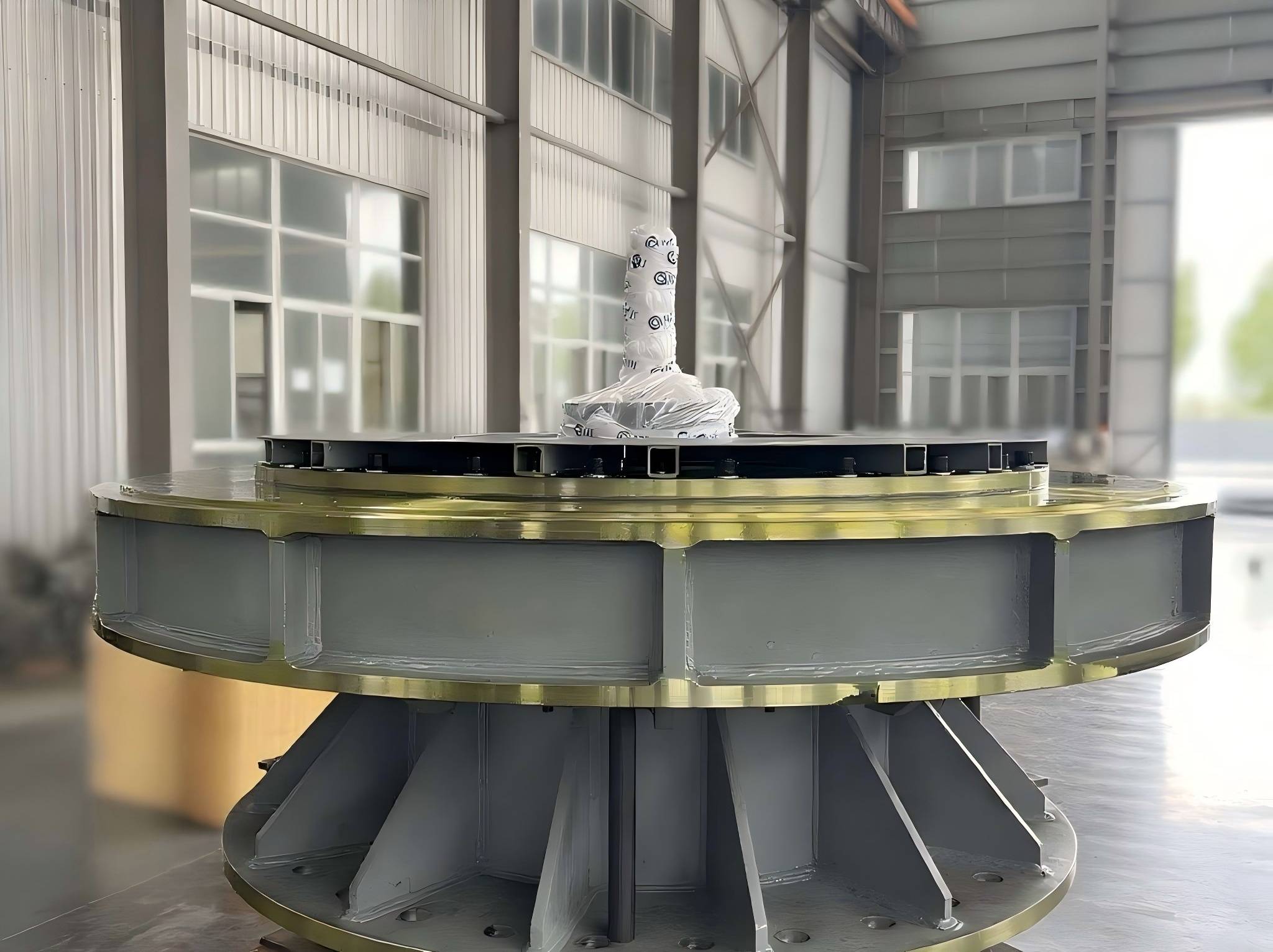

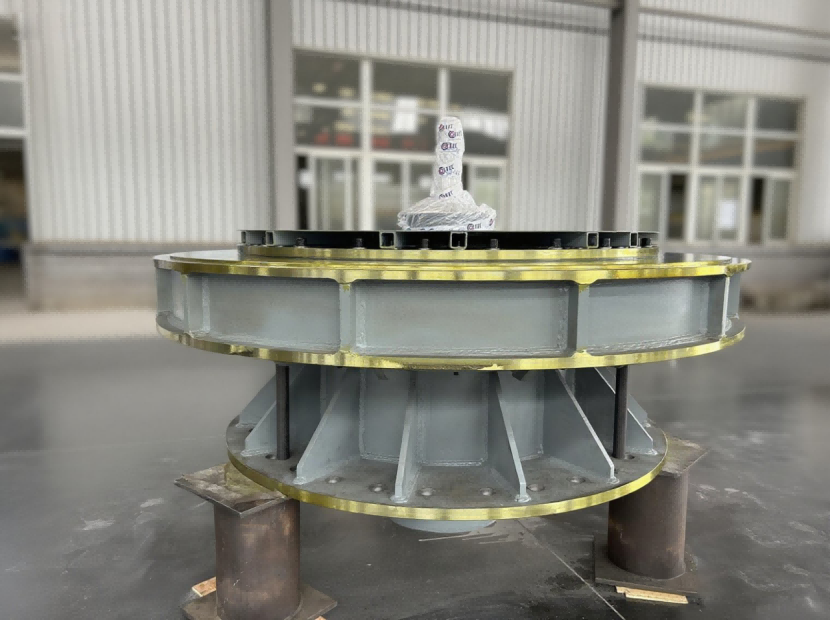

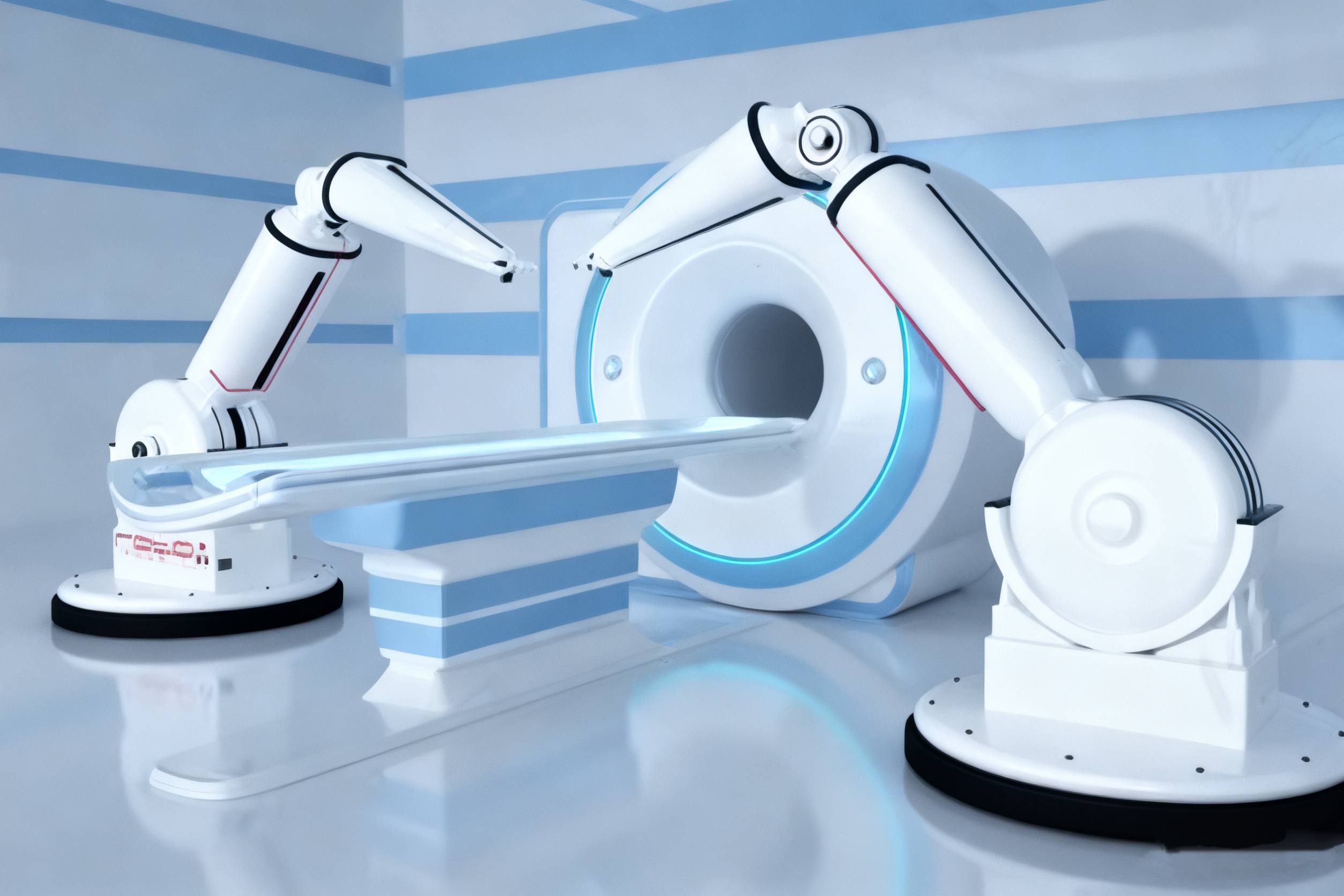

LTZC slewing bearing manufacturer

LTZC Bearings is a trusted bearing manufacturer specializing in slewing bearings, slewing drives, and precision bearings. With advanced CNC machining equipment, comprehensive heat treatment, and strict quality control, our products meet international standards and are ISO certified.

We export high-quality industrial bearings to Germany, India, Russia, and Canada, earning over 10,000 satisfied customer feedbacks. With strong OEM and ODM capabilities, LTZC provides fast delivery and custom bearing solutions for heavy machinery, construction, and automation industries.

View Manufacturing Capabilities