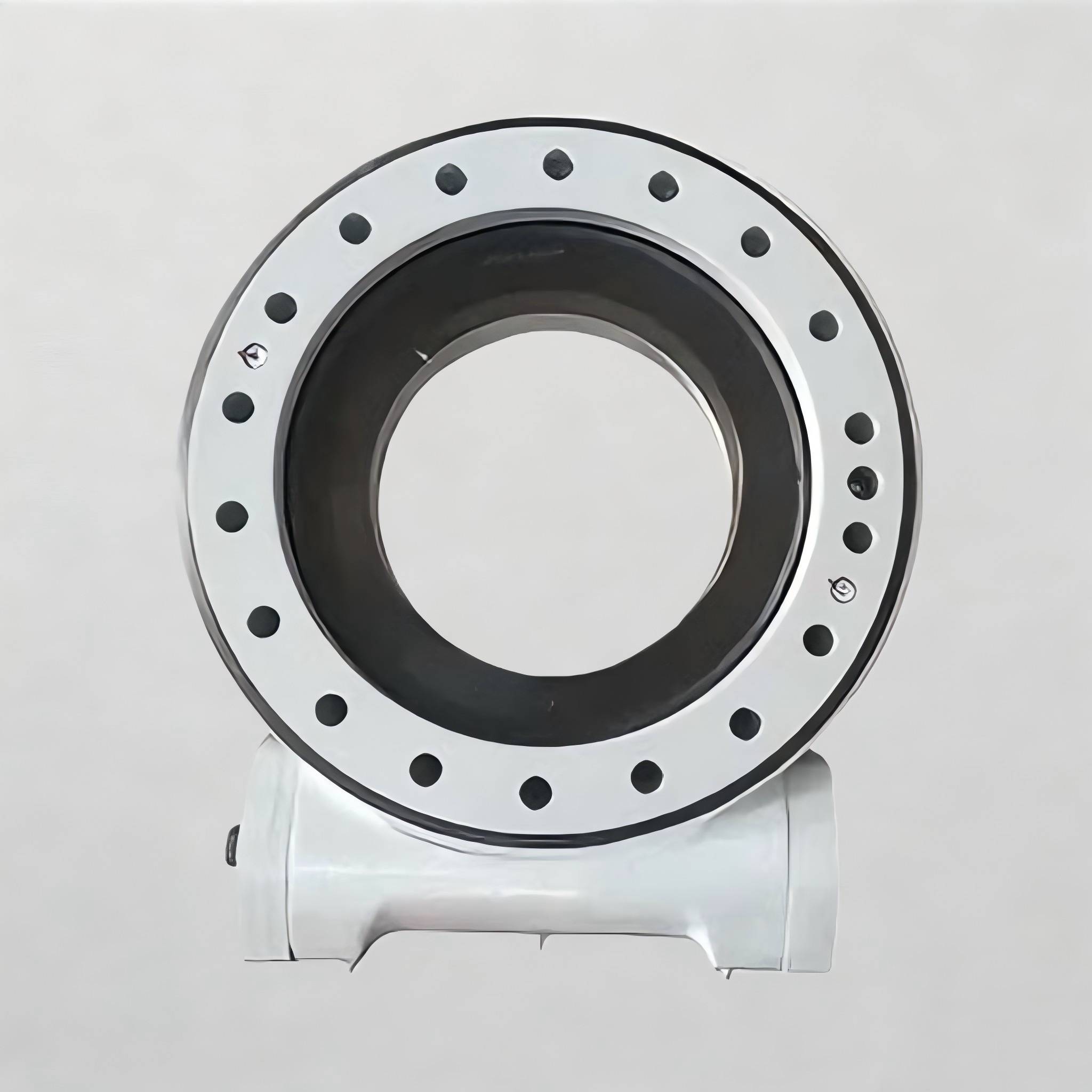

Worm Gear Slewing Drive

Worm gear slewing drive features

Compact Structure: The integrated design takes up little space and is easy to install.

High Torque Output: The large worm gear ratio provides strong output torque and overturning moment bearing capacity.

Excellent Self-Locking Performance: It maintains its position even in power outages or external forces, enhancing equipment safety.

Reliable Sealing: The fully enclosed housing withstands harsh outdoor environments.

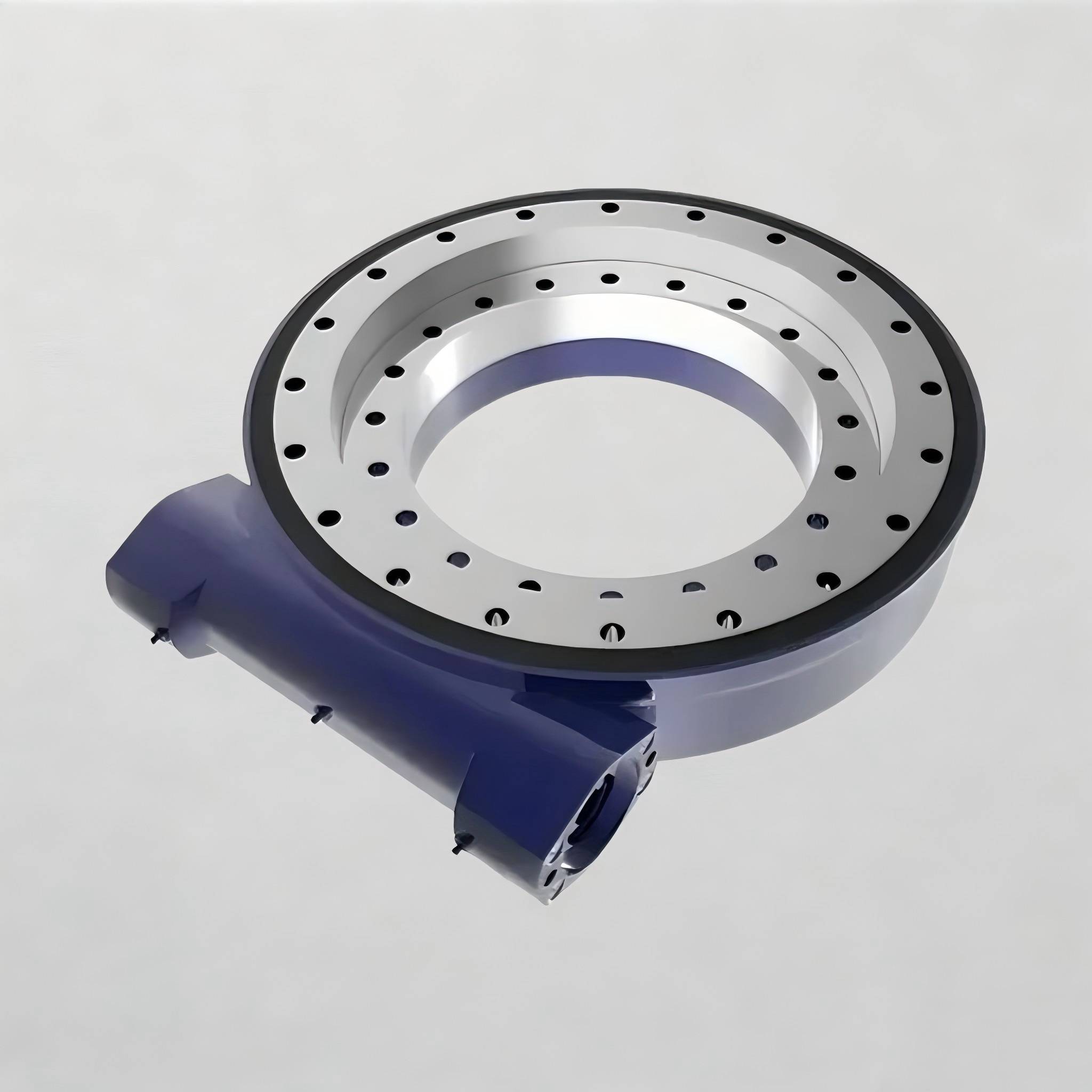

Worm gear slewing drive advantages

Strong load-bearing capacity: Simultaneously withstands axial loads, radial loads, and overturning moments, ensuring stable and reliable operation.

Long life and low maintenance: Made from high-strength alloy steel and high-quality bearing steel, combined with advanced heat treatment and precision machining processes.

Strong adaptability: Operates stably in complex environments, including high and low temperatures, windy sand, rain, and snow.

Worm gear slewing drive

| Type | Output | Overturning | Holding | Axial Static | Radial Static | Axial Dynamic | Radial Dynamic | Reduction Ratio | Accuracy Class | Weight |

|---|

| Torque | Moment | Torque | Load | Load | Load | Load |

|

|

|

|---|

| WE9 | 8 kN.m | 35.6 kN.m | 38.7 kN | 578 kN | 215 kN | 136 kN | 115 kN | 62:1 | <=0.15° | 48.5 Kg |

| 5904 lbf.ft | 26300 lbf.ft | 29000 lbf | 12900 lbf | 48300 lbf | 30600 lbf | 25900 lbf |

| WE12 | 9.5 kN.m | 57 kN.m | 43 kN.m | 760 kN | 280 kN | 190 kN | 148 kN | 79:1 | <=0.15° | 61 Kg |

| 7011 lbf.ft | 42100 lbf.ft | 32000 lbf.ft | 17100 lbf | 62900 lbf | 42700 lbf | 33300 lbf |

| WE14 | 10.8 kN.m | 71.2 kN.m | 48 kN.m | 960 kN | 360 kN | 230 kN | 200 kN | 86:1 | <=0.13° | 68 Kg |

| 7970 lbf.ft | 52600 lbf.ft | 35000 lbf.ft | 215800 lbf | 80900 lbf | 51700 lbf | 44900 lbf |

| WE17 | 12.96 kN.m | 142.4 kN.m | 72.3 kN | 1166 kN | 425 kN | 280 kN | 231 kN | 104:1 | <=0.1° | 90 Kg |

| 9564 lbf.ft | 105000 lbf.ft | 5340 lbf.ft | 262000 lbf | 978800 lbf | 62900 lbf | 51900 lbf |

| WE21 | 28.7 kN.m | 203 kN.m | 105.8 kN | 1589 kN | 640 kN | 385 kN | 335 kN | 90:1 | <=0.1° | 169 Kg |

| 21180 lbf.ft | 150000 lbf.ft | 78100 lbf.ft | 359000 lbf | 144000 lbf | 87000 lbf | 75000 lbf |

| WE25 | 34.2 kN.m | 310 kN.m | 158.3 kN | 2360 kN | 945 kN | 590 kN | 470 kN | 104:1 | <=0.1° | 199 Kg |

| 25240 lbf.ft | 229000 lbf.ft | 117000 lbf.ft | 531000 lbf | 212000 lbf | 133000 lbf | 106000 lbf |