LTZC Bearing Manufacturer - Precision Medical Bearings

In the field of high-end medical equipment, bearings, though small, play a crucial role as the "joints" that determine equipment precision, patient safety, and overall health outcomes. From the smooth rotation of imaging diagnostic equipment (such as CT and MRI scanners) to the precise control of surgical robotic arms, and the stable operation of high-speed dental drills and laboratory centrifuges, all rely on high-performance precision bearings. As an expert deeply rooted in the field of precision bearing manufacturing, LTZC Bearing, with 20 years of experience in bearing research and development,specializes in medical bearings and provides customized bearing solutions. LTZC Bearing's precision manufacturing technology and rigorous quality management system provide reliable bearing solutions for medical equipment manufacturers worldwide.

What is Medical bearings?

Medical bearings are high-precision, high-reliability bearing products specifically developed and manufactured for medical equipment.

Applications: Imaging diagnostic equipment, CT scanners, magnetic resonance imaging (MRI) equipment, surgical robot joints, radiotherapy equipment, and other high-precision rotating equipment.

Special Materals

Commonly used materials include medical-grade stainless steel (such as 316L) and ceramics (silicon nitride Si₃N₄). Ceramic bearings offer advantages such as wear resistance, corrosion resistance, non-magnetic properties, and high-temperature sterilization capabilities, making them the preferred choice for high-end medical equipment.

High Precision and Low Friction

Tolerance grades typically reach P4 and above, with extremely low surface roughness of rolling elements and raceways, reducing operating noise and vibration, and meeting the imaging accuracy requirements of diagnostic equipment and the operational accuracy requirements of surgical equipment.

Sterile and Disinfectable

The bearing structure design avoids bacterial residue, and the surface is smooth and easy to clean; it can withstand common medical sterilization methods such as high-pressure steam sterilization and ethylene oxide disinfection, and its performance does not degrade after sterilization.

High Reliability and Long Lifespan

Medical equipment downtime can endanger patient safety; therefore, bearings need to operate stably for a long time with little or no maintenance, and have an extremely low failure rate.

What are the differences between medical bearings and industrial bearings?

| Characteristics | Medical Bearings | Industrial Bearings |

|---|---|---|

| Material Requirements | Medical-grade stainless steel/ceramics, non-magnetic | Carbon steel/regular stainless steel, no special magnetic requirements |

| Precision Grade | Ultra-high precision (P4 and above) | Generally P0–P6, meeting industrial working conditions |

| Disinfection Resistance | Resistant to multiple high-temperature/chemical disinfections | No disinfection requirements; some types not heat-resistant |

| Noise and Vibration | Extremely low noise and vibration | Meeting industrial use standards, with lower requirements |

| Reliability Requirements | Ultra-high reliability, zero-failure priority | Meeting service life requirements for working conditions |

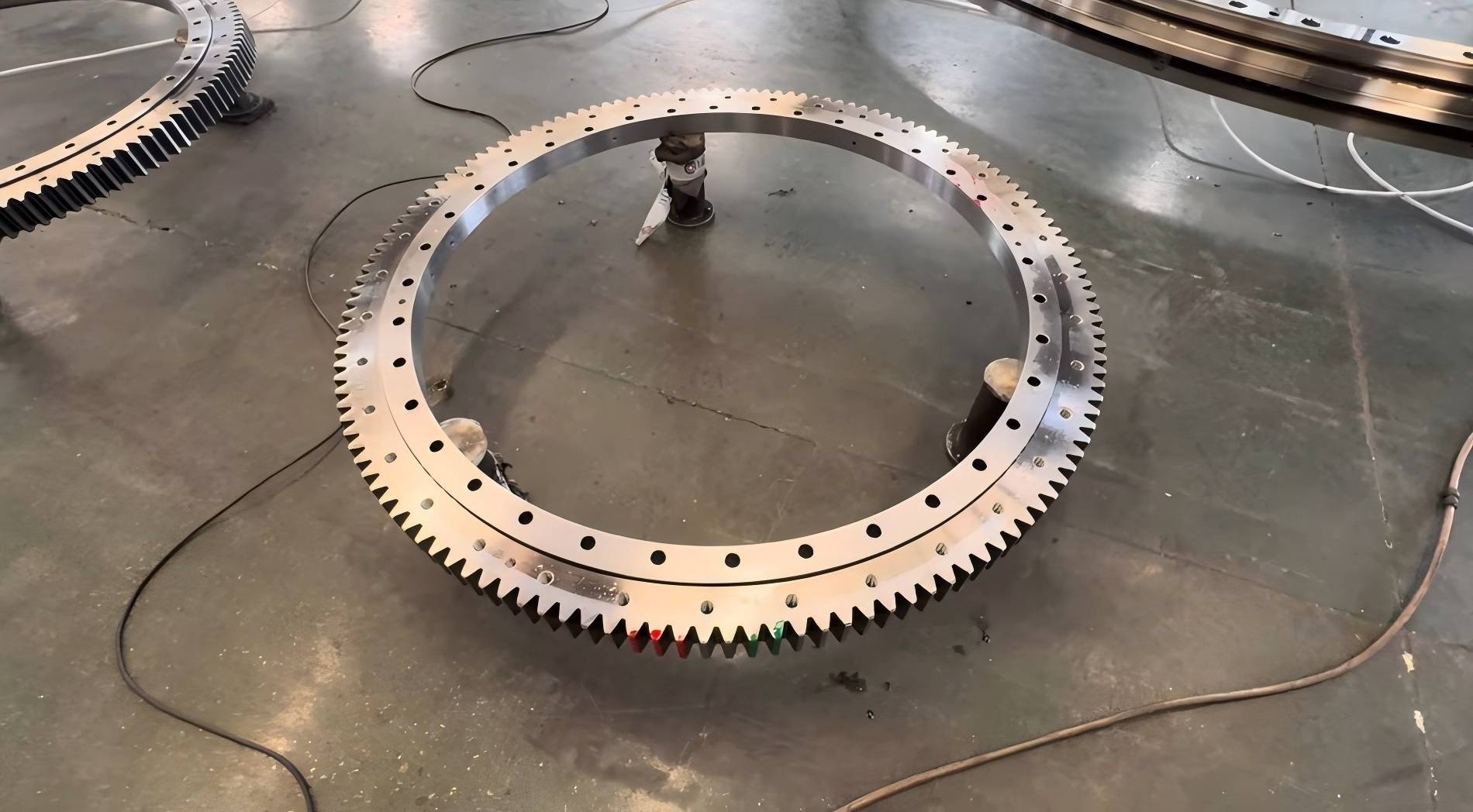

Case: High-Field Magnetic Resonance Imaging (MRI) Equipment – Ultra-Quiet Thin-section Slewing Bearing Solution

Customer Challenge: A leading medical imaging equipment manufacturer was developing a new generation of 3.0T open MRI systems. Their movable scanning bed required a large, low-profile slewing bearing capable of supporting patient weight and smoothly moving to the center of the magnet. The bearing had to be absolutely silent during operation and exhibit extremely low periodic motion errors.

LTZC bearing Solution:

Product Model: LTZC-SBMRI-800 series customized thin-section slewing bearing.

Key Parameters and Technologies:

Material: Both the rings and rolling elements are made of high-strength austenitic stainless steel 316L, specially demagnetized to ensure extremely low magnetic permeability (μ < 1.01).

Design: Features a four-point contact ball bearing design with an integrated precision gear ring, driven by a motor for precise translation and positioning of the scanning bed. The cross-section height is minimized to save valuable magnet gap space.

Accuracy: Rotational axial runout < 0.05mm, radial runout < 0.03mm.

Lubrication: Uses a special silicone-free, biocompatible fluorinated grease with stable performance over a wide temperature range and low volatility.

Noise Control: Utilizes an engineered plastic composite cage and optimized raceway surface finish, resulting in an unloaded operating noise level below 40 decibels (measured at 1 meter).

Results: The slewing bearing provided by LTZC not only operates ultra-quietly but also ensures high-precision bearing operation. The customer successfully launched the new product to the market and received positive feedback.

LTZC: China's Leading Slewing Bearing Manufacturer

With over 20 years of experience in bearing research and development, LTZC specializes in the manufacturing and development of slewing bearings. Its products range in size from 300mm to 12000mm, providing slewing bearings and precision bearings for heavy machinery such as cranes, excavators, tunnel boring machines, and wind turbines. LTZC products hold ISO 9001, 14001, 45001, CCS, BV, and ABS certifications,complying with the highest international quality standards and earning widespread recognition from the industry and customers.

View LTZC manufacturing capabilities

Looking ahead, with the rapid development of precision medicine, remote surgery, and wearable medical devices, there is a growing demand for smaller, smarter, and more bio-integrated bearings. LTZC will continue to invest in R&D, striving to remain the most trusted innovation partner for global medical equipment manufacturers.

Choosing the right bearing partner is crucial. LTZC, specializing in the professional manufacturing of slewing bearings and providing customized bearing solutions, is a trustworthy partner on your journey of medical equipment innovation.