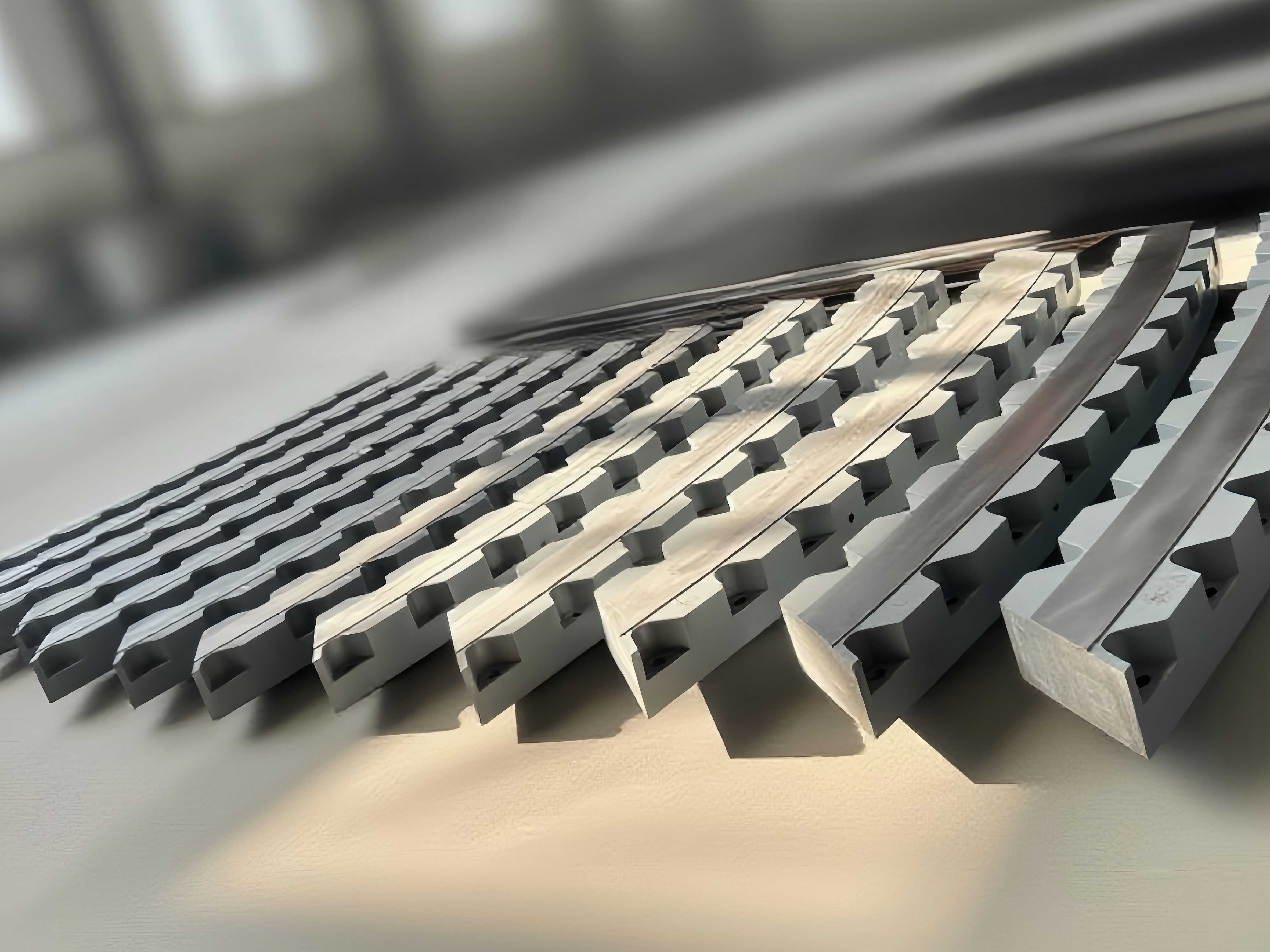

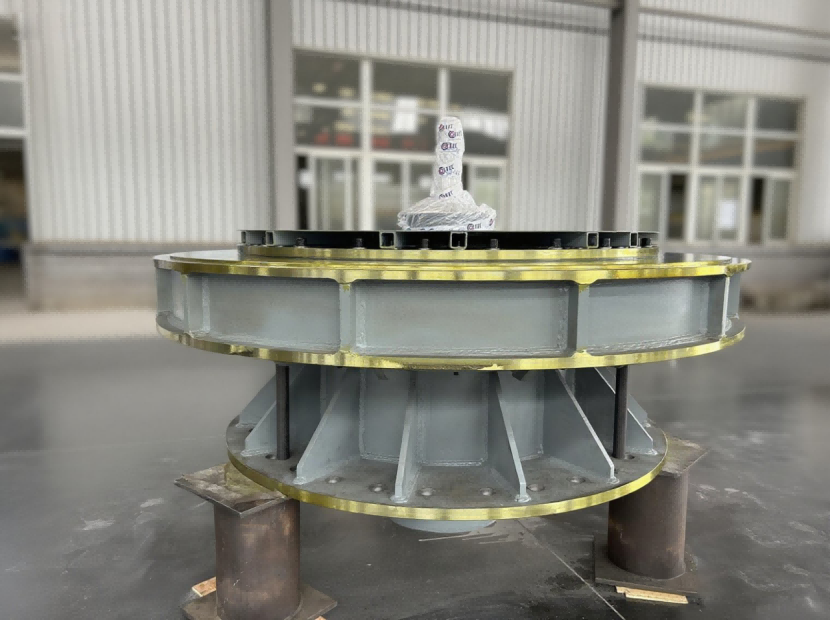

Segmented Track

LTZC Segmented track advantages

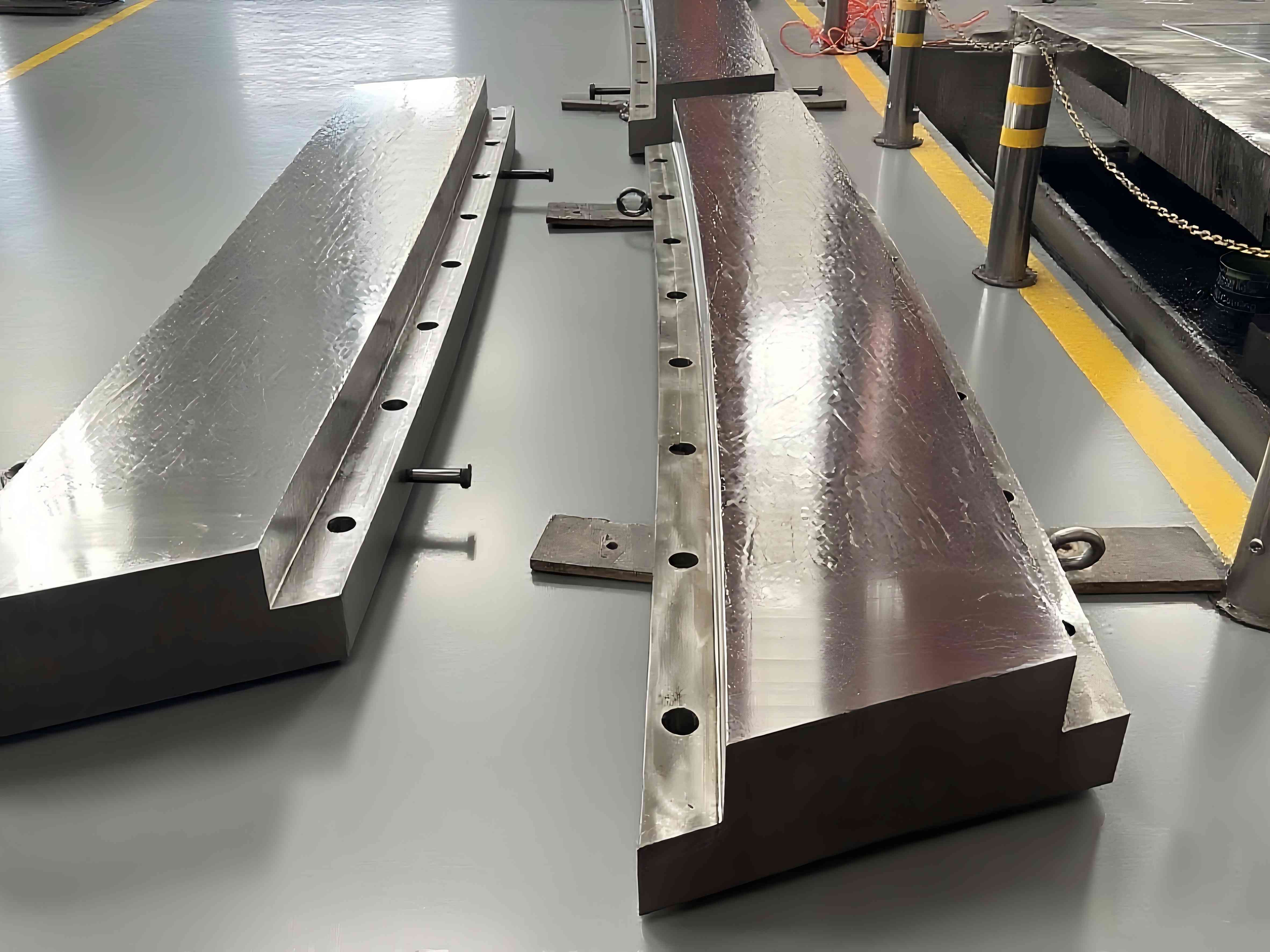

Suitable for Ultra-Large Diameter Equipment

LTZC segmented track enable the assembly oflarge-diameter structures ranging from Ø 3m to Ø 20m+, breaking through the limitations of full-circle machining dimensions. They are particularly suitable for wind power, port equipment, marine platforms, and large rotating structures.

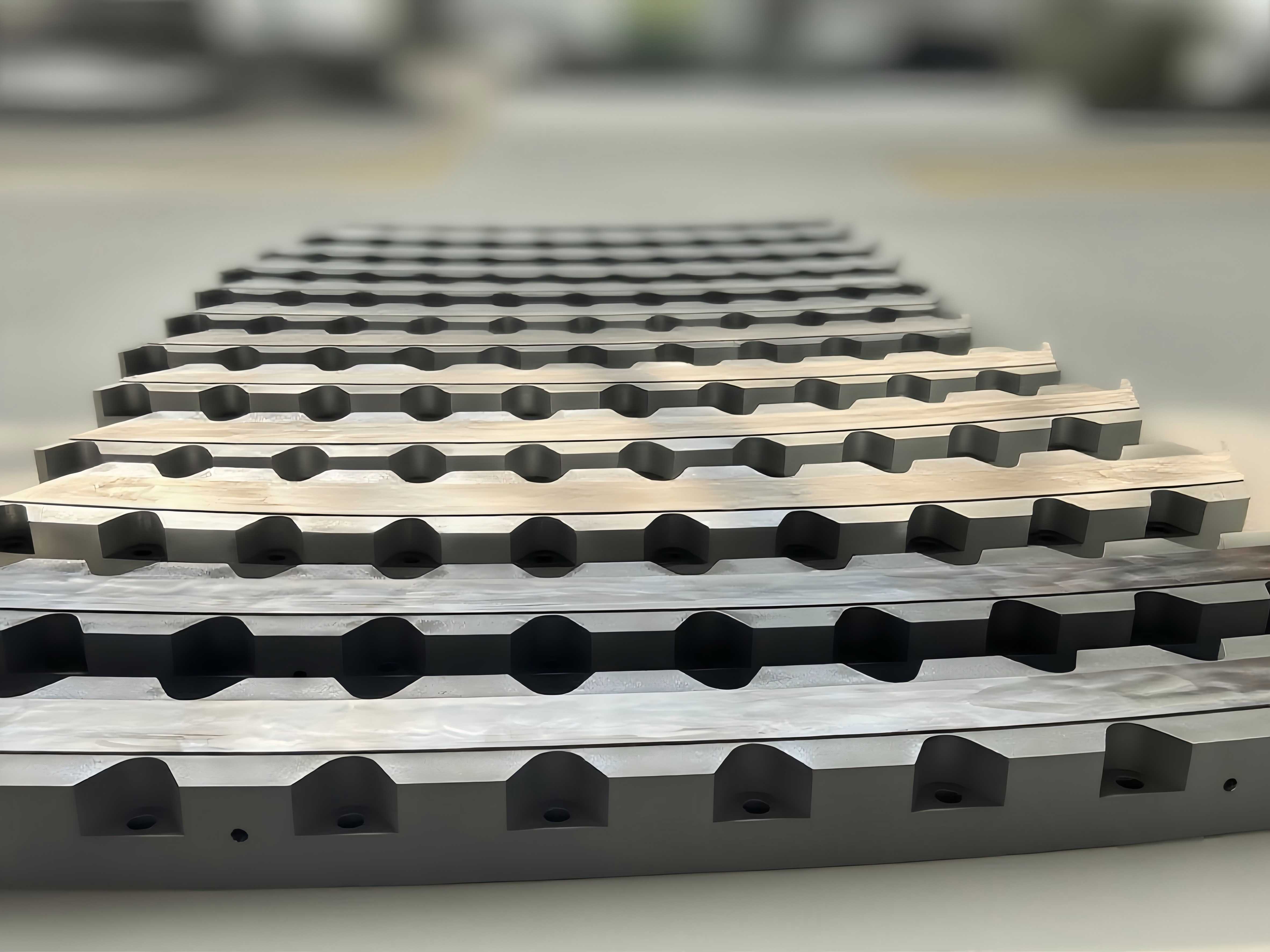

High-Precision Segmented Machining and Assembly Control

Utilizing LTZC's five-axis machining center and CNC gear grinding equipment, the end face, gear profile, and hole tolerances of segmented rails can be maintained within ±0.02–0.05 mm, ensuring overall roundness and meshing accuracy after assembly.

More Convenient Transportation and Construction

LTZC's segmented track design significantly reduces transportation difficulty and hoisting complexity, allowing for rapid on-site assembly. Transportation costs are reduced by 20%–40% compared to full-circle structures.

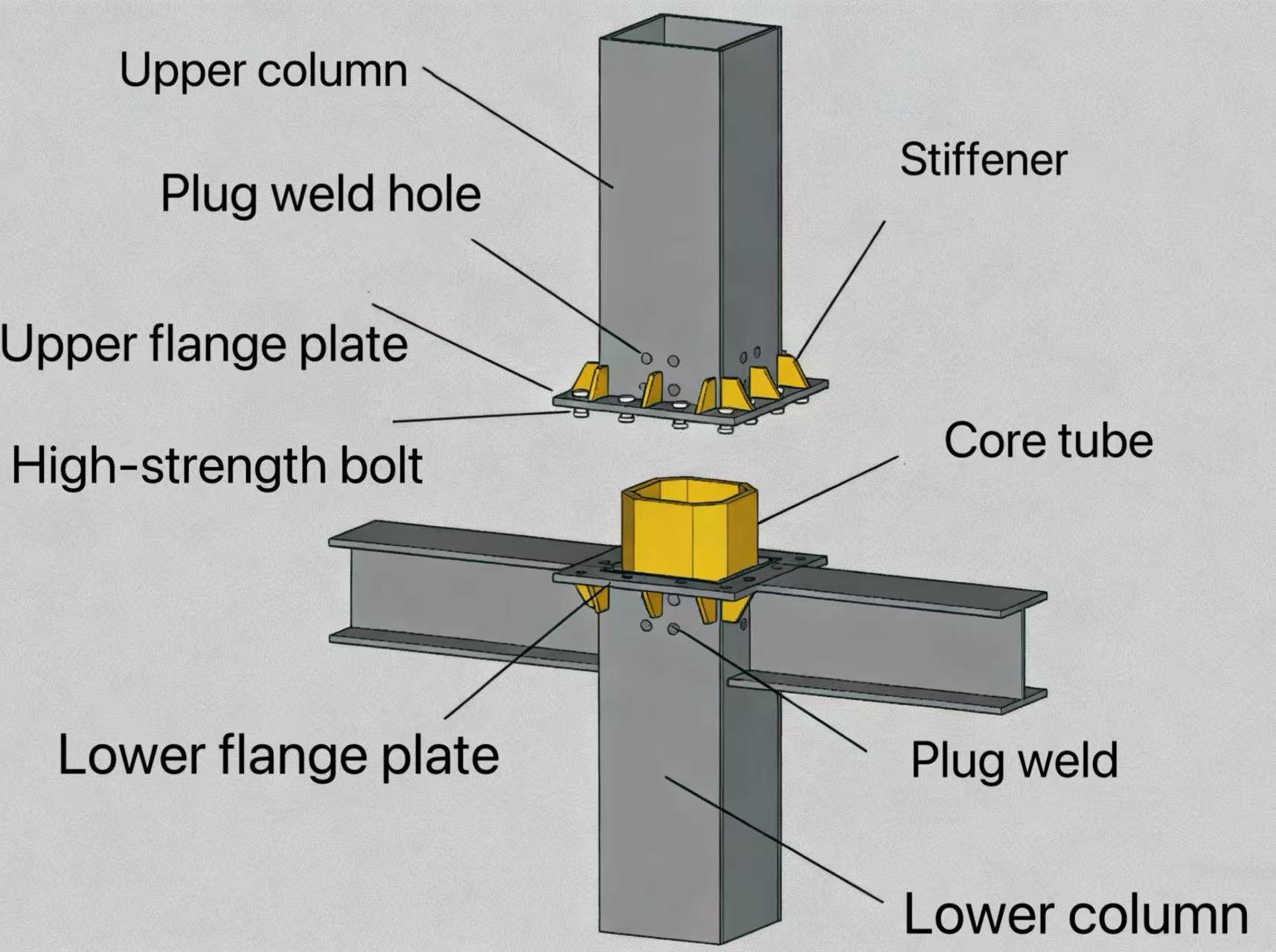

Stable Structure and High Strength

Using LTZC's proprietary material system and heat treatment process, each rail segment has a uniform hardness distribution (typical surface hardness 55–62 HRC),with overall strength and lifespan consistent with full-circle rails.

Reduced Maintenance Costs

When localized wear occurs, individual track sections can be replaced as needed, eliminating the need for complete disassembly and significantly reducing downtime and maintenance costs.

LTZC's End-to-End Manufacturing Capabilities

From raw material forging, ring segment forming, precision machining, grinding, testing, to anti-corrosion coating, all processes are independently completed by the LTZC production system, ensuring controllable product quality and batch stability.

International Certifications Guarantee Reliability

LTZC segmented tracks and related structural components meet ISO9001, ISO 14001, and ISO 45001 system requirements, and CCS, BV, and ABS marine-grade certifications can be provided upon request, making them suitable for demanding industries.