Angular Contact Ball Bearing

Angular Contact Ball Bearing features

1. Angular contact structure: The raceway has a specific contact angle of 15°, 25°, or 40°. The larger the contact angle, the stronger the axial load capacity.

2. When used in pairs (O-type, X-type, back-to-back configuration), it can greatly improve the positioning accuracy of the system.

3. Superior high-speed capability compared to most roller bearings: The lightweight steel ball rolling elements have low rolling resistance, and the reasonable contact angle design gives angular contact ball bearings excellent high-speed performance.

4. High precision bearing grades: Available in P5, P4, and P2 grades, with strict control over raceway roundness, roughness, and clearance, suitable for high-end equipment.

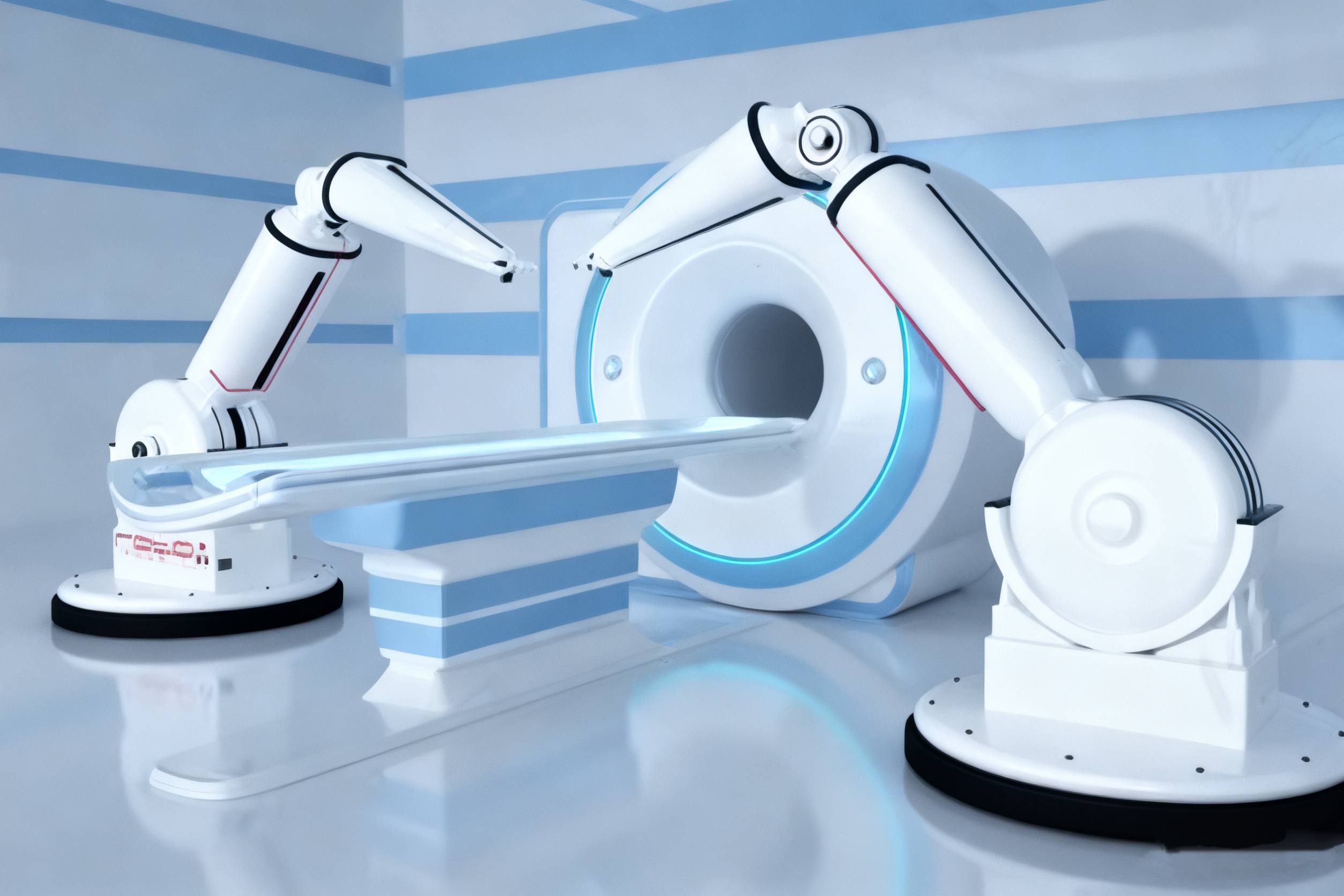

5. Applications: High-speed machine tool spindles, industrial robot joints, high-speed motors, precision medical equipment.

Get LTZC technical support

Angular Contact Ball Bearing advantage

1. High-rigidity structure supports the needs of high-precision equipment.

LTZC angular contact ball bearings excel in double, triple, and quadruple configurations, and are particularly suitable for machine tool spindles, robot joints, and high-speed systems.

2. Optimized materials and heat treatment enhance lifespan and wear resistance.

High-grade bearing steels (such as 42CrMo and 50Mn) are used, and multi-zone temperature-controlled quenching ensures uniform raceway hardness and high fatigue resistance.

3. Customizable sealing, dustproofing, and lubrication options are available.

High-performance bearing greases and contact/non-contact seals enable stable operation in complex environments.

4. Strict quality system ensures consistency and traceability.

Based on LTZC's comprehensive testing system (roundness testing, clearance testing, vibration testing, etc.), all angular contact ball bearings achieve high consistency and full-process traceability.

Get a quote for LTZC bearings

View LTZC quality and certifications

View LTZC manufacturing capabilities

See the LTZC production site

Angular Contact Ball Thin Section Bearings

| Bearing Model | d (inch/mm) | D (inch/mm) | Cor (N) | Cr (N) | Coa (N) | Ca (N) | Weight (Kg) |

|---|

| KAA10AG0 | 1.000 / 25.400 | 1.375 / 34.925 | 1510 | 670 | 4310 | 2000 | 0.011 |

| KAA15AG0 | 1.500 / 38.100 | 1.875 / 47.625 | 2130 | 890 | 6130 | 3250 | 0.017 |

| KAA17AG0 | 1.750 / 44.450 | 2.125 / 53.975 | 2220 | 2060 | 6760 | 3600 | 0.020 |

| KA020AR0 | 2.000 / 50.800 | 2.500 / 63.500 | 3510 | 1470 | 10140 | 4270 | 0.045 |

| KA025AR0 | 2.500 / 63.500 | 3.000 / 76.200 | 4270 | 1690 | 12360 | 4271 | 0.054 |

| KA030AR0 | 3.000 / 76.200 | 3.500 / 88.900 | 5070 | 1910 | 14620 | 4272 | 0.064 |

| KA035AR0 | 3.500 / 88.900 | 4.000 / 101.600 | 5830 | 2090 | 16850 | 4273 | 0.077 |

| KA040AR0 | 4.000 / 101.600 | 4.500 / 114.300 | 6630 | 2270 | 19110 | 4274 | 0.086 |

| KA042AR0 | 4.250 / 107.950 | 4.750 / 120.650 | 7020 | 2360 | 20230 | 4275 | 0.091 |

| KA045AR0 | 4.500 / 114.300 | 5.000 / 127.000 | 7380 | 2450 | 21380 | 4276 | 0.095 |

| KA047AR0 | 4.750 / 120.650 | 5.250 / 133.350 | 7780 | 2530 | 22490 | 4277 | 0.100 |

| KA050AR0 | 5.000 / 127.000 | 5.500 / 139.700 | 8180 | 2620 | 23600 | 4278 | 0.104 |

| KA055AR0 | 5.500 / 139.700 | 6.000 / 152.400 | 8980 | 2760 | 25870 | 4279 | 0.113 |

| KA060AR0 | 6.000 / 152.400 | 6.500 / 165.100 | 9740 | 2930 | 28090 | 4280 | 0.127 |

| KA065AR0 | 6.500 / 165.100 | 7.000 / 177.800 | 10540 | 3070 | 30360 | 4281 | 0.136 |

| KA070AR0 | 7.000 / 177.800 | 7.500 / 190.500 | 11290 | 3250 | 32630 | 4282 | 0.145 |

| KA075AR0 | 7.500 / 190.500 | 8.000 / 203.200 | 12090 | 3380 | 34850 | 4283 | 0.154 |

| KA080AR0 | 8.000 / 203.200 | 8.500 / 215.900 | 12850 | 3510 | 37120 | 4284 | 0.163 |

| KA090AR0 | 9.000 / 228.600 | 9.500 / 241.300 | 14400 | 3780 | 41610 | 4285 | 0.186 |

| KA100AR0 | 10.000 / 254.000 | 10.500 / 266.700 | 15960 | 4050 | 46100 | 4286 | 0.204 |

| KA110AR0 | 11.000 / 279.400 | 11.500 / 292.100 | 17510 | 4310 | 50580 | 4287 | 0.227 |

| KA120AR0 | 12.000 / 304.800 | 12.500 / 317.500 | 19070 | 4580 | 55070 | 4288 | 0.245 |