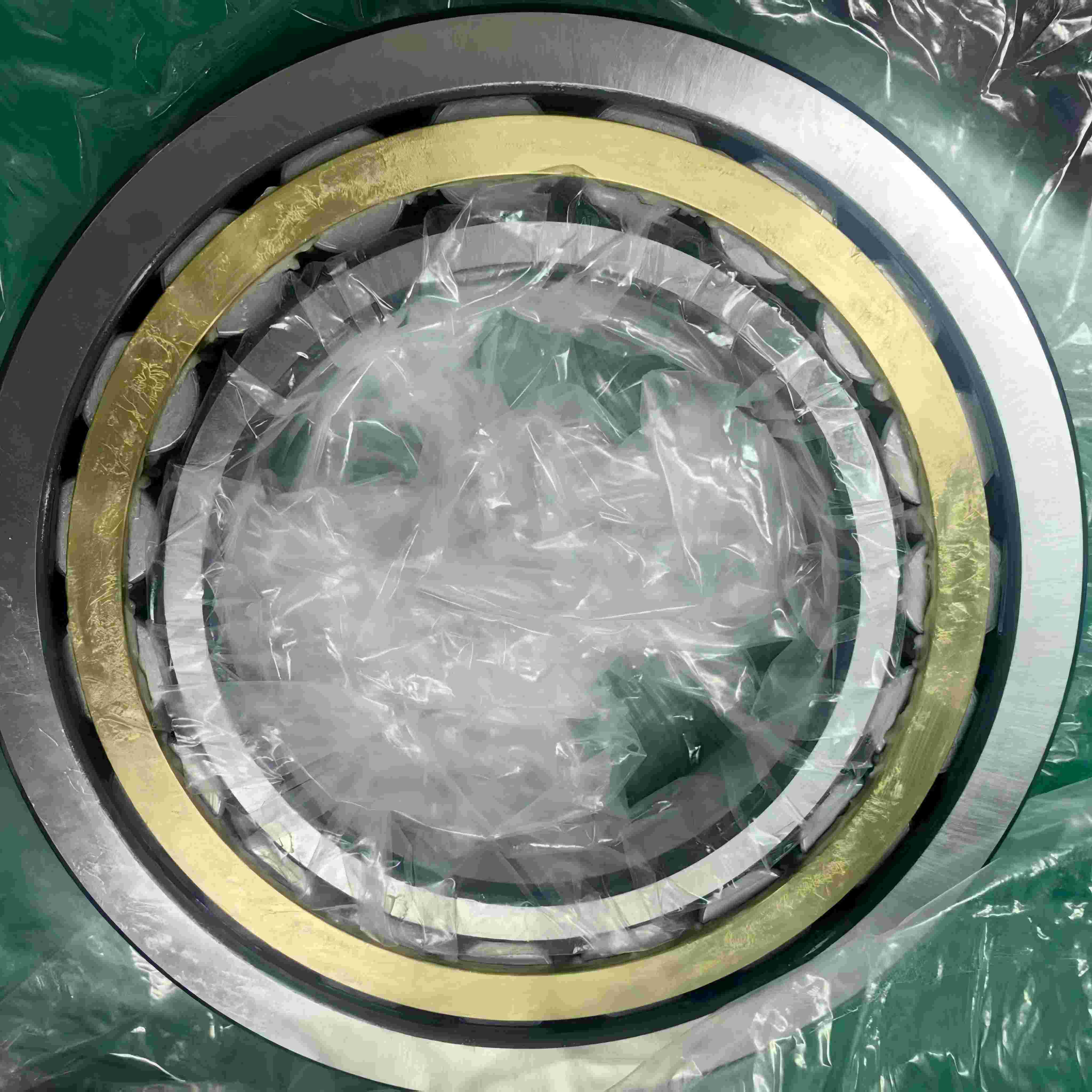

Deep Groove Ball Bearing

Deep groove ball bearings features

1. Lightweight Bearing Structure: Thin-section deep groove ball bearings are designed with the core concept of "minimum cross-section, maximum load capacity," significantly reducing raceway thickness while maintaining precision.

2. Precision Bearing Manufacturing: Thin-section deep groove ball bearings typically employ integral precision machining, fine surface treatment, and strict clearance control, maintaining low noise, low vibration, and smooth dynamic performance even at high speeds.

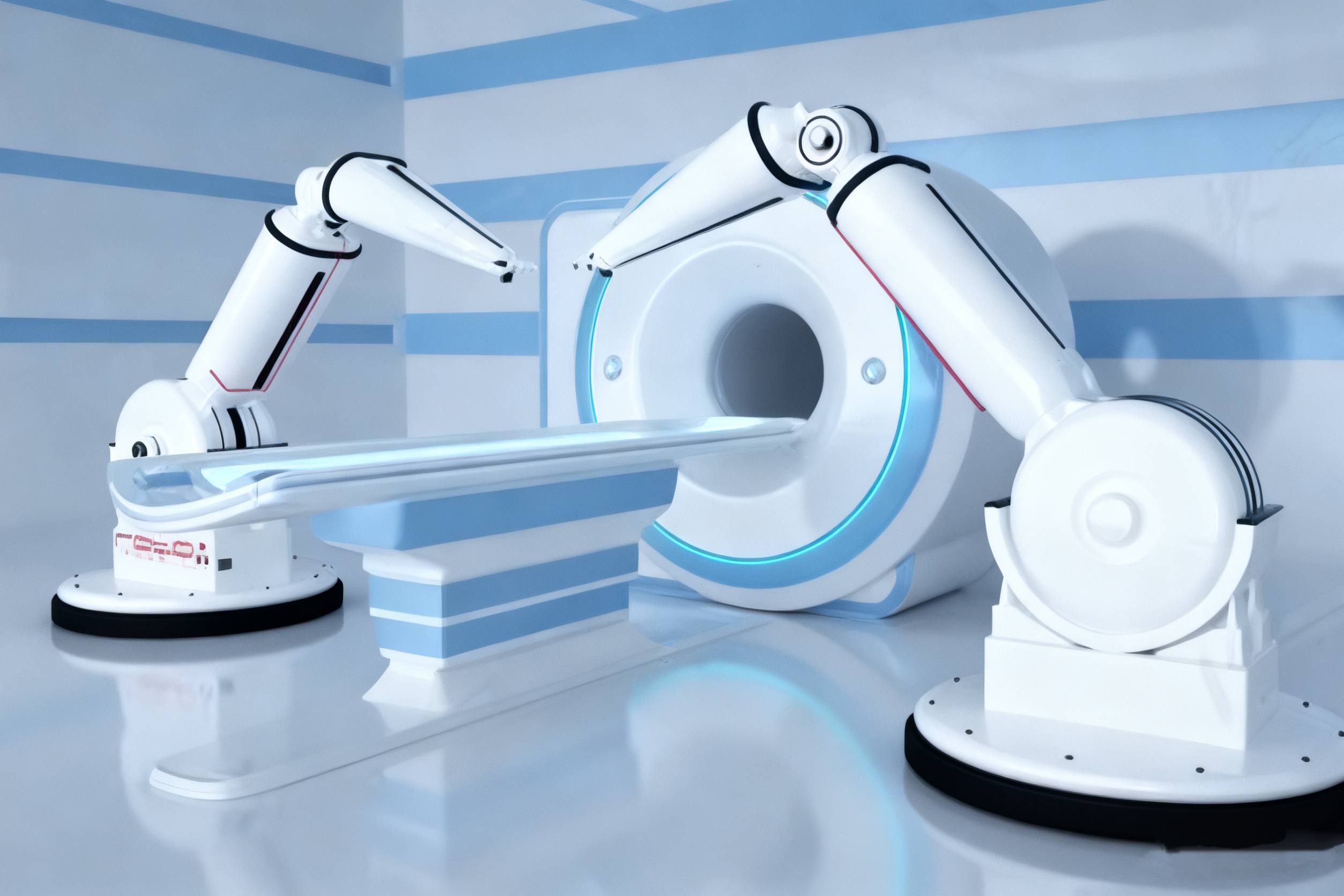

3. Applications: Robot joints, medical diagnostic equipment, precision measurement platforms, aerospace and lightweight transmission mechanisms, automation and lightweight components.

Deep groove ball bearings advantages

1. High-precision raceway machining ensures smoother rotation performance.

LTZC employs CNC grinding and precision raceway machining technology to create a stable deep groove contact line between the steel balls and the raceways, improving bearing stability.

2. LTZC uses superior high-grade bearing steels 50Mn and 42CrMo, along with induction hardening technology, to enhance bearing life and reliability.

3. Wide range of lightweight designs, customizable from thin-walled to heavy-duty types.

LTZC can design various bearing types to meet the needs of different industries, including thin-section deep groove ball bearings, thickened types, reinforced types, or those with sealed structures, taking into account various bearing characteristics.

4. Low frictional resistance, suitable for high-speed and energy-saving equipment

LTZC's optimized precision control and lubrication solutions result in bearings with lower frictional torque, suitable for: high-speed motors, precision transmission equipment, medical devices, robotics, etc.

View bearing application

5. Reliable sealing and lubrication control, enhancing environmental resistance

LTZC offers various sealing structures: single-lip, double-lip, contact/non-contact rubber seals, and metal protective caps. Combined with specialized bearing greases, this ensures stable performance of bearings even in complex environments, reducing maintenance frequency. Get LTZC technology support

6. Strict quality control system, ensuring overall consistency and traceability

LTZC implements full-process quality control from material arrival to raceway machining, hardness testing, clearance control, and final assembly, supported by ISO 9001, 14001, and 45001 series quality systems. The stability of dimensional, tolerance, and life control is significantly higher than that of ordinary manufacturers.

View LTZC quality and certifications

7. Large-size production capability to meet special industry and non-standard needs

Unlike typical deep groove ball bearing manufacturers, LTZC can produce large-size deep groove ball bearings with diameters ranging from 500 mm to 3000 mm.

Customized bearing

Deep Groove Ball Thin-Section Bearing Open Type (C)

| Bearing Model | d (inch/mm) | D (inch/mm) | Cor (N) | Cr (N) | Weight (Kg) | Interchange |

|---|

| KAA10CP0 | 1.000 / 25.400 | 1.375 / 34.925 | 1290 | 670 | 0.012 | KAA10CP0 |

| KAA15CP0 | 1.500 / 38.100 | 1.875 / 47.625 | 1780 | 800 | 0.018 | KAA15CP0 |

| KAA17CP0 | 1.750 / 44.450 | 2.125 / 53.975 | 2110 | 1770 | 0.020 | KAA17CP0 |

| KA020CP0 | 2.000 / 50.800 | 2.500 / 63.500 | 3020 | 1420 | 0.048 | KA020CP0 |

| KA025CP0 | 2.500 / 63.500 | 3.000 / 76.200 | 3690 | 1600 | 0.059 | KA025CP0 |

| KA030CP0 | 3.000 / 76.200 | 3.500 / 88.900 | 4400 | 1820 | 0.068 | KA030CP0 |

| KA035CP0 | 3.500 / 88.900 | 4.000 / 101.600 | 5070 | 2000 | 0.082 | KA035CP0 |

| KA040CP0 | 4.000 / 101.600 | 4.500 / 114.300 | 5730 | 2130 | 0.090 | KA040CP0 |

| KA042CP0 | 4.250 / 107.950 | 4.750 / 120.650 | 6090 | 2220 | 0.095 | KA042CP0 |

| KA045CP0 | 4.500 / 114.300 | 5.000 / 127.000 | 6400 | 2310 | 0.100 | KA045CP0 |

| KA047CP0 | 4.750 / 120.650 | 5.250 / 133.350 | 6760 | 2400 | 0.104 | KA047CP0 |

| KA050CP0 | 5.000 / 127.000 | 5.500 / 139.700 | 7070 | 2490 | 0.109 | KA050CP0 |

Deep Groove Ball Thin-Section Bearing Open Type (C)

| Bearing Model | d (inch/mm) | D (inch/mm) | Cor (N) | Cr (N) | Weight (Kg) | Interchange |

|---|

| KB020CP0 | 2.000 / 50.800 | 2.625 / 66.675 | 4130 | 2000 | 0.073 | KB020CP0 |

| KB025CP0 | 2.500 / 63.500 | 3.125 / 79.375 | 5070 | 2310 | 0.091 | KB025CP0 |

| KB030CP0 | 3.000 / 76.200 | 3.625 / 92.075 | 5960 | 2580 | 0.109 | KB030CP0 |

| KB035CP0 | 3.500 / 88.900 | 4.125 / 104.775 | 6850 | 2800 | 0.125 | KB035CP0 |

| KB040CP0 | 4.000 / 101.600 | 4.625 / 117.475 | 7780 | 3070 | 0.140 | KB040CP0 |

| KB042CP0 | 4.250 / 107.950 | 4.875 / 123.825 | 8130 | 3160 | 0.147 | KB042CP0 |

| KB045CP0 | 4.500 / 114.300 | 5.125 / 130.175 | 8670 | 3290 | 0.160 | KB045CP0 |

| KB047CP0 | 4.750 / 120.650 | 5.375 / 136.525 | 9020 | 3380 | 0.163 | KB047CP0 |

| KB050CP0 | 5.000 / 127.000 | 5.625 / 142.875 | 9560 | 3510 | 0.172 | KB050CP0 |

| KB055CP0 | 5.500 / 139.700 | 6.125 / 155.575 | 10490 | 3730 | 0.186 | KB055CP0 |

| KB060CP0 | 6.000 / 152.400 | 6.625 / 168.275 | 11380 | 3960 | 0.205 | KB060CP0 |

| KB065CP0 | 6.500 / 165.100 | 7.125 / 180.975 | 12270 | 4130 | 0.216 | KB065CP0 |

| KB070CP0 | 7.000 / 177.800 | 7.625 / 193.675 | 13200 | 4360 | 0.232 | KB070CP0 |

| KB075CP0 | 7.500 / 190.500 | 8.125 / 206.375 | 14090 | 4530 | 0.250 | KB075CP0 |

| KB080CP0 | 8.000 / 203.200 | 8.625 / 219.075 | 14980 | 4760 | 0.262 | KB080CP0 |

| KB090CP0 | 9.000 / 228.600 | 9.625 / 244.475 | 16800 | 5110 | 0.300 | KB090CP0 |

| KB100CP0 | 10.000 / 254.000 | 10.625 / 269.875 | 18620 | 5470 | 0.331 | KB100CP0 |

| KB110CP0 | 11.000 / 279.400 | 11.625 / 295.275 | 20400 | 5820 | 0.360 | KB110CP0 |

| KB120CP0 | 12.000 / 304.800 | 12.625 / 320.675 | 22230 | 6180 | 0.390 | KB120CP0 |

| KB140CP0 | 14.000 / 355.600 | 14.625 / 371.475 | 25830 | 6800 | 0.476 | KB140CP0 |

| KB160CP0 | 16.000 / 406.400 | 16.625 / 422.275 | 29430 | 7420 | 0.544 | KB160CP0 |

| KB180CP0 | 18.000 / 457.200 | 18.625 / 473.075 | 33070 | 8050 | 0.612 | KB180CP0 |

| KB200CP0 | 20.000 / 508.000 | 20.625 / 523.875 | 36670 | 8620 | 0.680 | KB200CP0 |