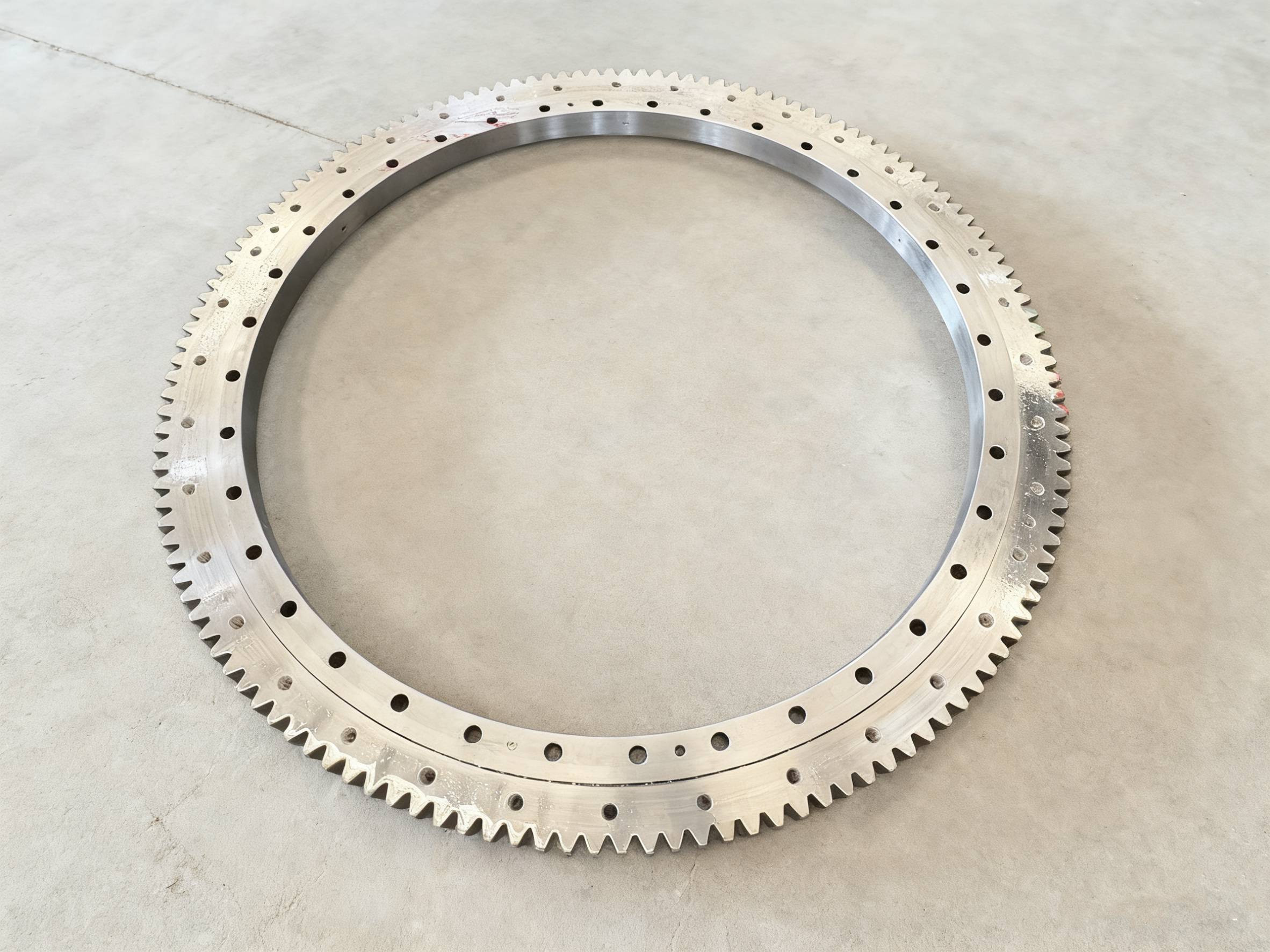

Flanged Slewing Bearing

What is flang slewing bearing?

Flanged slewing bearings are a special type of slewing bearing designed with flanges added to one or both sides of the inner or outer ring. These flanges have pre-drilled mounting holes for quick and easy installation. They are widely used in applications such as robotic arms, automated equipment, aerospace lifting platforms, small cranes, medical equipment, rotary worktables, and vehicle-mounted systems, where compactness, lightweight design, and ease of installation are crucial requirements.

How to mount a flanged bearing?

1. Check the slewing bearing flange, grease holes, and seals for damage, and verify that the bearing model matches the equipment.

2. Clean the bearing surface. Wipe the bearing flange surface, raceway surface, and mounting seat connecting surface with a degreasing agent to remove rust-proof oil, dust, iron filings, and other impurities, preventing impurities from entering the raceway after installation and causing wear.

3. Perform datum positioning. Align the flange surface of the slewing bearing with the mounting surface of the equipment, ensuring that their centers coincide. Use a feeler gauge to check the fit clearance; the clearance should be uniform and no greater than 0.05 mm.

4. Install the bolts using a cross-symmetrical tightening method. Insert the bolts and washers in a diagonal sequence, and manually tighten the nuts until they are flush with the flange surface.

5. After installation, manually rotate the inner ring of the bearing. The rotation should be smooth, without jamming or abnormal noise, and the rotational resistance should be uniform.

6. Perform regular inspections and maintenance. If insufficient lubrication or damaged seals are found, maintenance should be carried out promptly to prevent secondary wear on the slewing bearing.

Flang slewing bearing advantages

LTZC flange bearings possess a significant advantage in the industry thanks to their superior manufacturing capabilities and complete production system. Utilizing high-precision machining equipment and rigorous quality control, LTZC achieves fully in-house production from raw material forging, heat treatment, precision machining to assembly and inspection. This ensures the high load-bearing capacity and long service life of every flange bearing, and the bearings hold ISO9001, 14001, 45001, CCS, BV, and ABS certifications.

The flange bearings feature a compact design and convenient installation, maintaining stable operation under radial loads, axial loads, and overturning moments. They are suitable for various complex working conditions, including hoisting machinery, wind power equipment, and offshore platforms. Benefiting from LTZC's industry reputation in the field of heavy-duty and large-size bearings, users can obtain reliable product guarantees, customized solutions, and rapid delivery support, fully demonstrating LTZC's technical strength in the field of precision bearings.

Get the bearing solutions

| Precision Grade | Bore Tolerance (φ50 mm) | Outer Diameter Tolerance (φ90 mm) | Radial Runout | Axial Runout | Raceway Roundness Error | Raceway Surface Roughness Ra |

|---|

| P0 | 0 ~ -10 μm | 0 ~ -13 μm | ≤ 15 μm | ≤ 15 μm | ±0.015 mm | ≤ 1.6 μm |

| P6 | 0 ~ -8 μm | 0 ~ -8 μm | ≤ 10 μm | ≤ 10 μm | ±0.010 mm | ≤ 1.25 μm |

| P5 | 0 ~ -6 μm | 0 ~ -5 μm | ≤ 6 μm | ≤ 8 μm | ±0.008 mm | ≤ 0.8 μm |

| P4 | 0 ~ -5 μm | 0 ~ -3 μm | ≤ 3 μm | ≤ 4 μm | ±0.005 mm | ≤ 0.4 μm |

| P2 | 0 ~ -3 μm | 0 ~ -2 μm | ≤ 2 μm | ≤ 3 μm | ±0.003 mm | ≤ 0.2 μm |

Flanged Slewing Bearing

| Designation | Weight (kg) | Da | D | d | H | H2 | D1 | D2 | nl | n2 | Φ1 | Φ2 | d2 | b | h | bh | dl | D3 |

|---|

| VLI200414N ZT | 28.5 | 325 | 518 | 350 | 56 | 415.5 | 490 | 375 | 8 | 12 | 18 | M12 | 458.5 | 40 | 11.5 | 44.5 | 600 | 412.5 |

| VLI 20 0414N ZT RL2 | 36.3 | 325 | 518 | 350 | 56 | 415.5 | 490 | 375 | 8 | 12 | 18 | M12 | 456 | 40 | 11.5 | 44.5 | 300 | 412.5 |

| VLI200414N | 27.5 | 325 | 518 | 350 | 56 | 415.5 | 490 | 375 | 8 | 12 | 18 | M12 |

| 40 | 8.5 | 44.5 | 295 | 412.5 |

| 232.20.0400.013 | 27.1 | 326.5 | 518 | 350 | 56 | 415.5 | 490 | 375 | 8 | 12 | 18 | M12 | 45.5 | 10.5 | 45.5 | 45.5 | 250 | 412.5 |

| 232.20.0400.503 | 26.9 | 326.5 | 518 | 350 | 56 | 415.5 | 490 | 375 | 16 | 12 | 18 | M12 | 45.5 | 10.5 | 45.5 | 45.5 | 250 | 412.5 |

| 232.21.0475.013 | 27.1 | 326.5 | 517 | 350 | 56 | 415.5 | 490 | 375 | 8 | 12 | 18 | M12 | 45.5 | 10.5 | 45.5 | 45.5 | 250 | 411.0 |

| I.505.20.00.C | 35.4 | 326.5 | 518 | 350 | 56 | 415.5 | 490 | 375 | 8 | 12 | 18 | M12 | 453 | 46 | 10 | 46 | 500 | 412.5 |

| VLI200544N ZT | 40.6 | 444 | 648 |

| 56 | 545.5 | 620 | 505 | 10 | 16 | 18 | M12 | 588.5 | 44.5 | 11.5 | 44.5 | 790 | 542.5 |

| VLI200544N | 38 | 444 | 648 |

| 56 | 545.5 | 620 | 505 | 10 | 16 | 18 | M12 |

| 44.5 | 11.5 | 44.5 | 385 | 542.5 |

| 232.20.0500.013 | 36.9 | 445.2 | 648 |

| 56 | 545.5 | 620 | 505 | 10 | 16 | 18 | M12 | 45.5 | 10.5 | 45.5 | 45.5 | 330 | 542.5 |

| 232.20.0500.503 | 36.7 | 445.2 | 648 |

| 56 | 545.5 | 620 | 505 | 20 | 16 | 18 | M12 | 45.5 | 10.5 | 45.5 | 45.5 | 330 | 542.5 |

| 232.21.0575.013 | 36.9 | 445.2 | 647 |

| 56 | 545.5 | 620 | 505 | 10 | 16 | 18 | M12 | 45.5 | 10.5 | 45.5 | 45.5 | 330 | 541.0 |