Dual-Axis Slewing Drive

Dual-axis slewing drive features

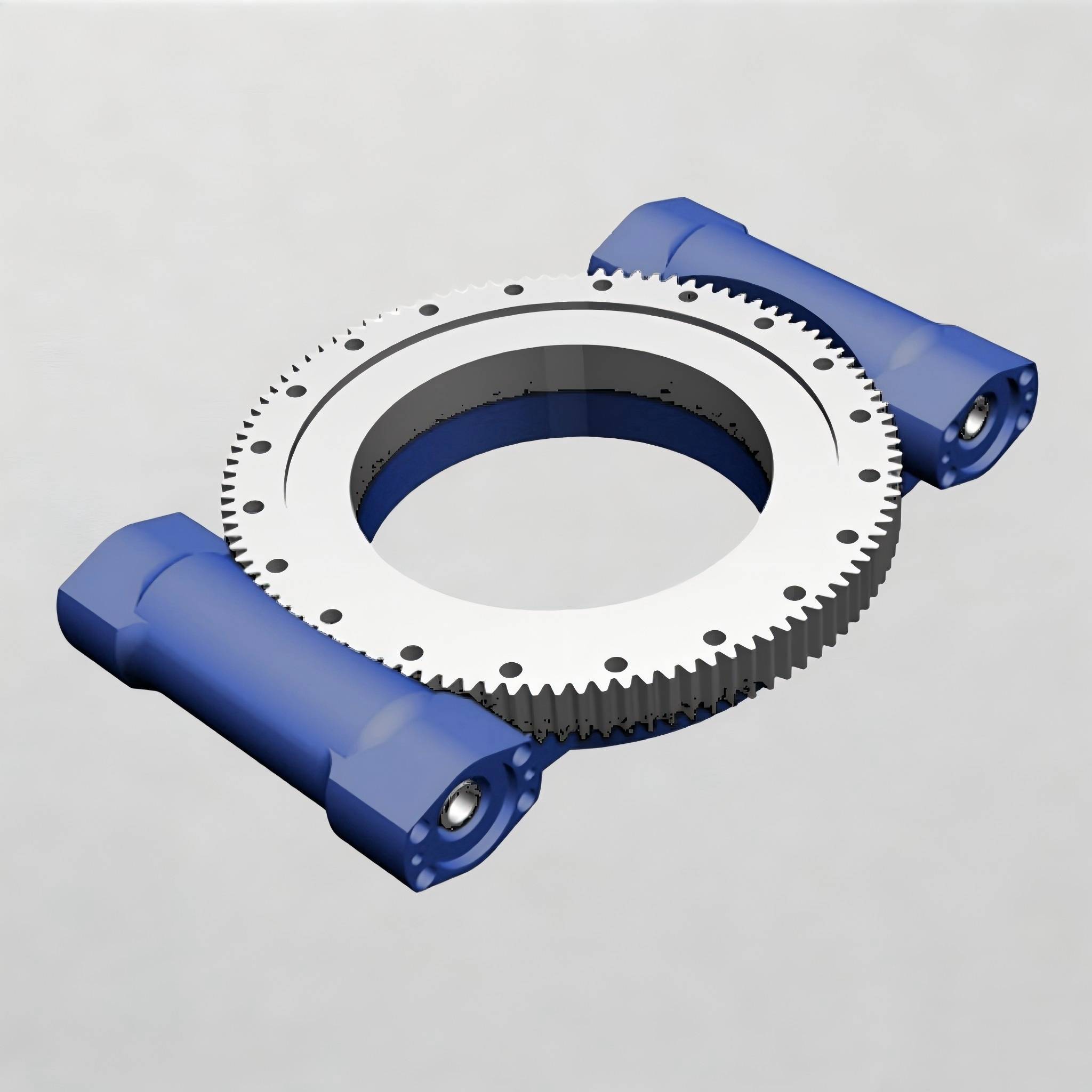

A dual-axis slewing drive is a precision transmission device integrating two rotational degrees of freedom, allowing simultaneous rotational motion around two orthogonal axes. It is typically divided into a "pitch axis" and a "rotation axis," with the two axes arranged orthogonally at 90°. It is commonly used in equipment requiring multi-directional attitude adjustment and is an upgraded structure based on single-axis slewing drives.

Multi-degree-of-freedom motion: Compared to single-axis slewing drives, it can achieve two-dimensional rotation in space, meeting the needs of complex attitude adjustments.

High-precision positioning: Both axes utilize worm gear transmission, providing a stable transmission ratio. Combined with limit sensors, the positioning accuracy can reach ±0.1°.

High load capacity: The dual-slewing bearing design allows it to withstand multi-directional forces and torques simultaneously, making it suitable for heavy-duty equipment.

Dual-axis slewing drive advantages

LTZC's Complete Machining System

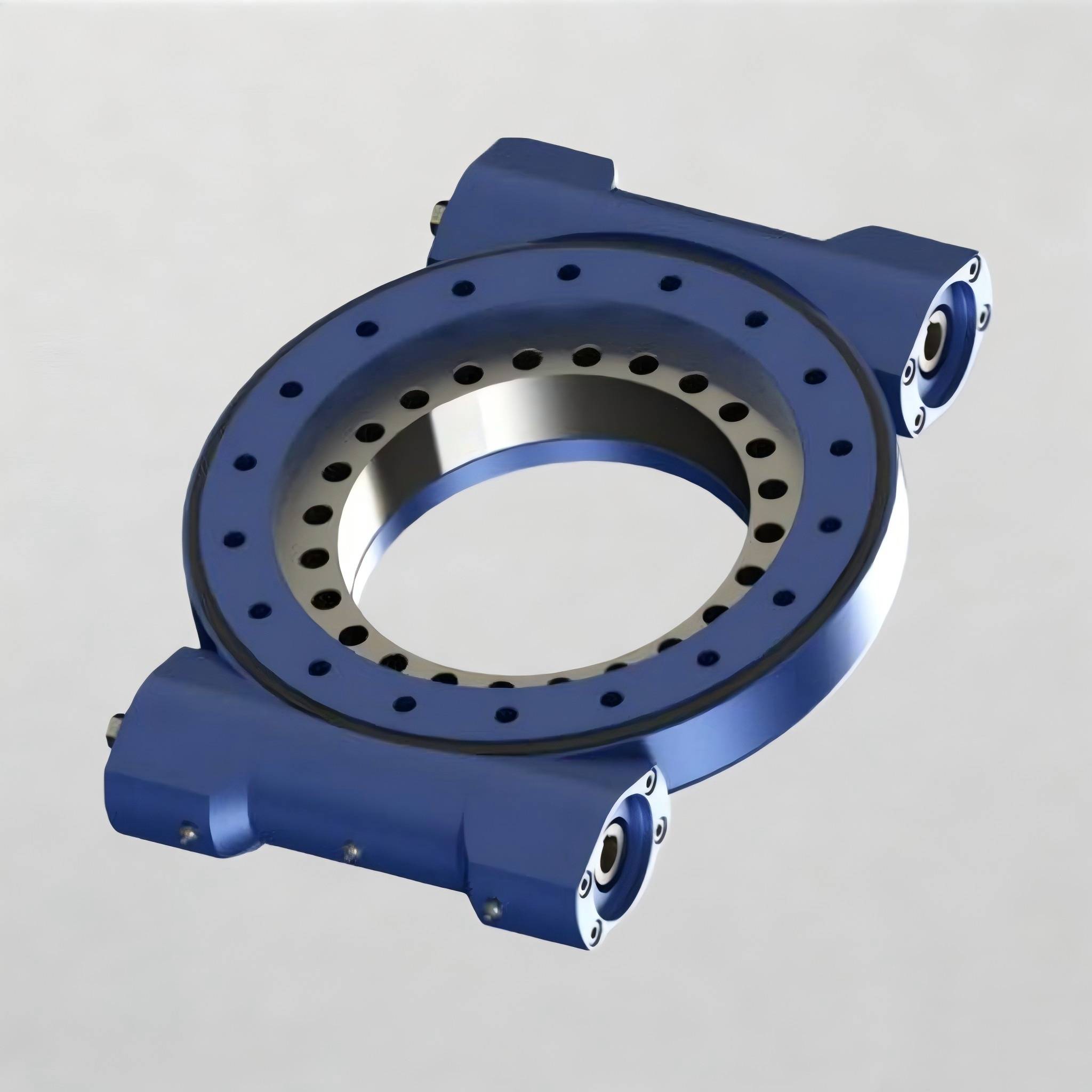

Leveraging LTZC's large-scale CNC machining, quenching, and gear grinding capabilities, the dual-axis drive boasts higher load-bearing capacity and structural strength.

Compact Integration, Easier Installation

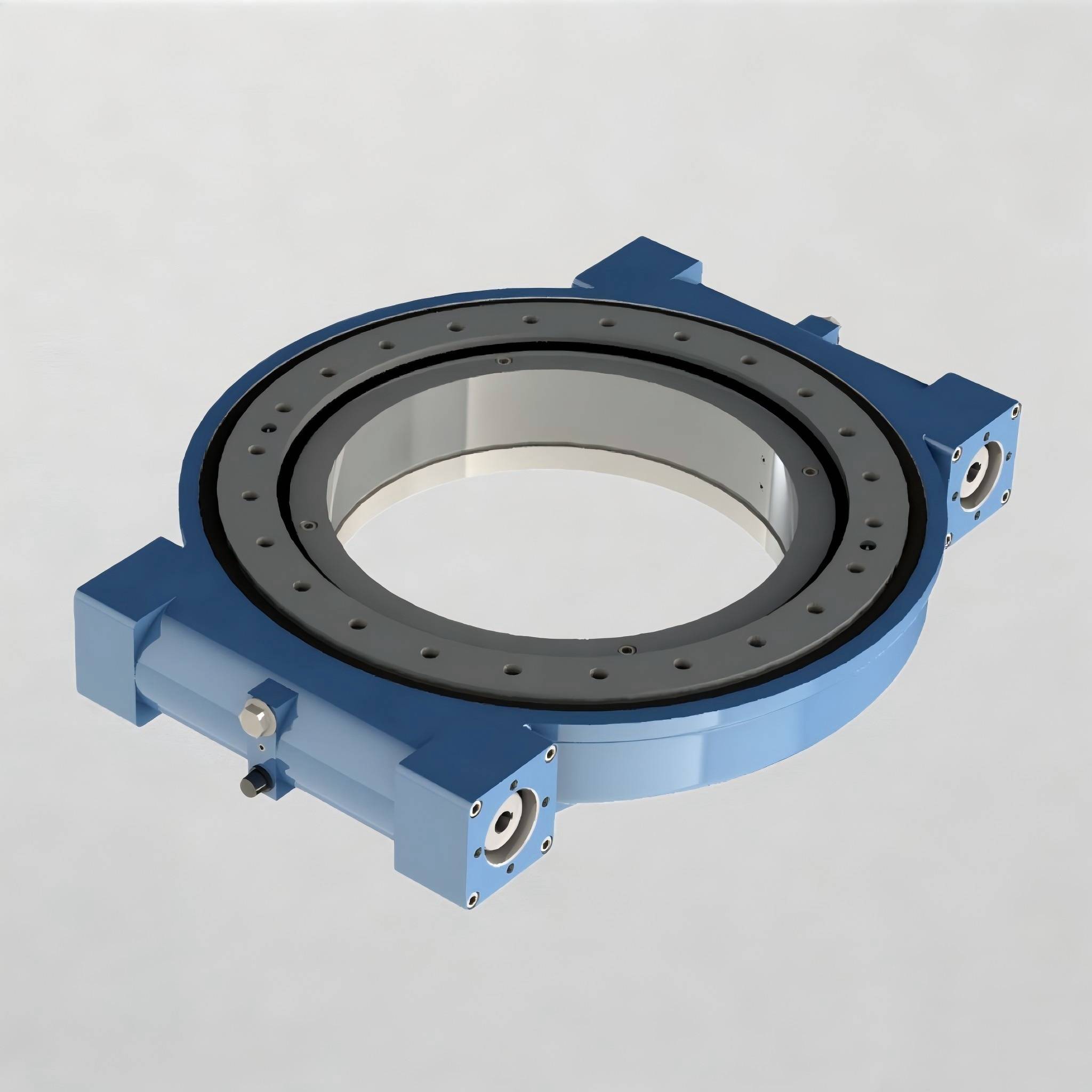

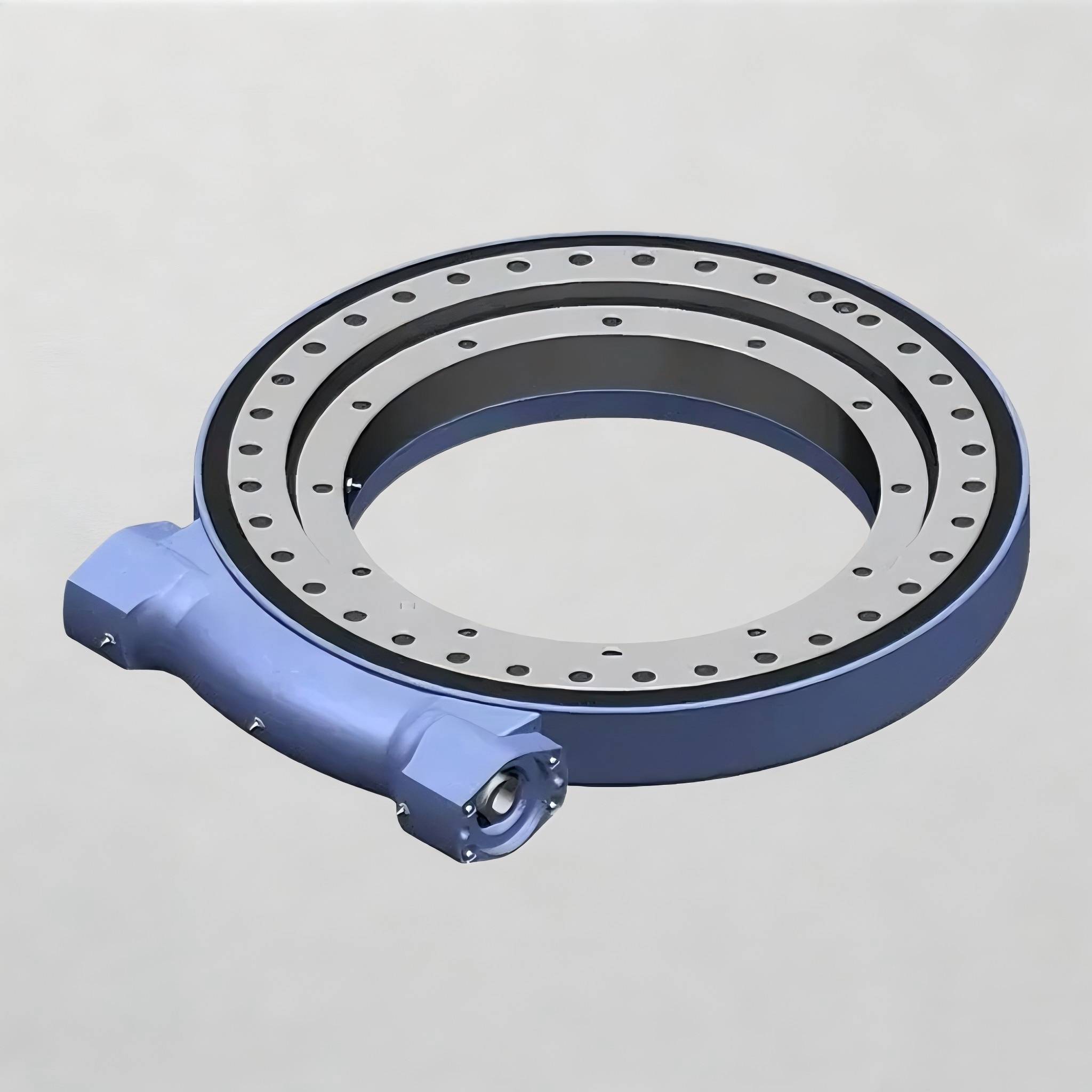

LTZC highly integrates the slewing bearing, drive, seals ring, and mounting interface, achieving a lightweight design that reduces equipment footprint and facilitates faster assembly.

Precision Bearing Tooth Machining

The slewing gears utilize LTZC's high-precision gear grinding technology, ensuring smooth meshing, low noise, and controllable backlash to meet high-precision positioning requirements.

Strong Sealing and Environmental Resistance, Adaptable to Multiple Industry Applications

LTZC's dual-axis slewing drive employs seals such as FKM and PTFE, providing excellent dustproof, waterproof, and corrosion-resistant structures, suitable for various scenarios including outdoor, marine, construction machinery, and robotics.

Customizable slewing Drive Solutions

LTZC supports servo motors, hydraulic drives, rotary gearboxes, and multiple mounting orientations, offering a complete solution from design and manufacturing to testing.

Applications of dual-axis rotary drives:

Solar thermal/photovoltaic power generation tracking systems (tracking the sun's azimuth and elevation angle)

Attitude adjustment devices for radar antennas and satellite communication antennas

High-altitude work platforms for construction machinery and boom adjustment mechanisms for lifting machinery

Security monitoring pan-tilt systems and aiming systems for military weapons and equipment

Get LTZC technical support Get a quote for LTZC bearings View LTZC quality and certifications

Dual-axis slewing drive parameter

| Type | Performance Parameters | Weight |

|---|

| Output Torque | Overturning Moment | Holding Torque | Axial Static Load | Radial Static Load | Axial Dynamic Load | Radial Dynamic Load | Reduction Ratio | Accuracy Class |

|---|

| WEA7 | 3.5 kN·m

2583 lbf·ft | 14.2 kN·m

10500 lbf·ft | 20 kN

14800 lbf·ft | 220 kN

49500 lbf | 90 kN

20200 lbf | 63 kN

14200 lbf | 48 kN

10800 lbf | 47:1 | <=0.15° | 35 Kg |

| WEA9 | 8 kN·m

5904 lbf·ft | 35.6 kN·m

26300 lbf·ft | 38.7 kN

28000 lbf·ft | 578 kN

1129900 lbf | 215 kN

48300 lbf | 136 kN

30600 lbf | 115 kN

25900 lbf | 62:1 | <=0.15° | 53 Kg |

| WEA12 | 9.5 kN·m

7011 lbf·ft | 57 kN·m

42100 lbf·ft | 43 kN

32000 lbf·ft | 760 kN

17100 lbf | 280 kN

62900 lbf | 190 kN

42700 lbf | 148 kN

33300 lbf | 79:1 | <=0.15° | 66.8 Kg |

| WEA14 | 10.8 kN·m

7970 lbf·ft | 71.2 kN·m

52600 lbf·ft | 48 kN·m

35000 lbf·ft | 960 kN

215800 lbf | 360 kN

80900 lbf | 230 kN

51700 lbf | 200 kN

44900 lbf | 86:1 | <=0.13° | 75 Kg |

| WEA17 | 12.96 kN·m

9564 lbf·ft | 142.4 kN·m

105000 lbf·ft | 72.3 kN

5340 lbf·ft | 1166 kN

262000 lbf | 425 kN

978800 lbf | 280 kN

62900 lbf | 231 kN

51900 lbf | 104:1 | <=0.1° | 96 Kg |

| WEA19 | 18.5 kN·m

13653 lbf·ft | 196 kN·m

144600 lbf·ft | 86.7 kN

64000 lbf·ft | 1800 kN

404600 lbf | 675 kN

151700 lbf | 290 kN

65200 lbf | 250 kN

56200 lbf | 93:1 | <=0.1° | 130 Kg |

| WEA21 | 28.7 kN·m

21180 lbf·ft | 203 kN·m

150000 lbf·ft | 105.8 kN

78100 lbf·ft | 1589 kN

359000 lbf | 640 kN

144000 lbf | 385 kN

87000 lbf | 335 kN

75000 lbf | 90:1 | <=0.1° | 172 Kg |

| WEA25 | 34.2 kN·m

25240 lbf·ft | 310 kN·m

229000 lbf·ft | 158.3 kN

117000 lbf·ft | 2360 kN

531000 lbf | 945 kN

212000 lbf | 590 kN

133000 lbf | 470 kN

106000 lbf | 104:1 | <=0.1° | 202 Kg |