Gear Type Slewing Drive

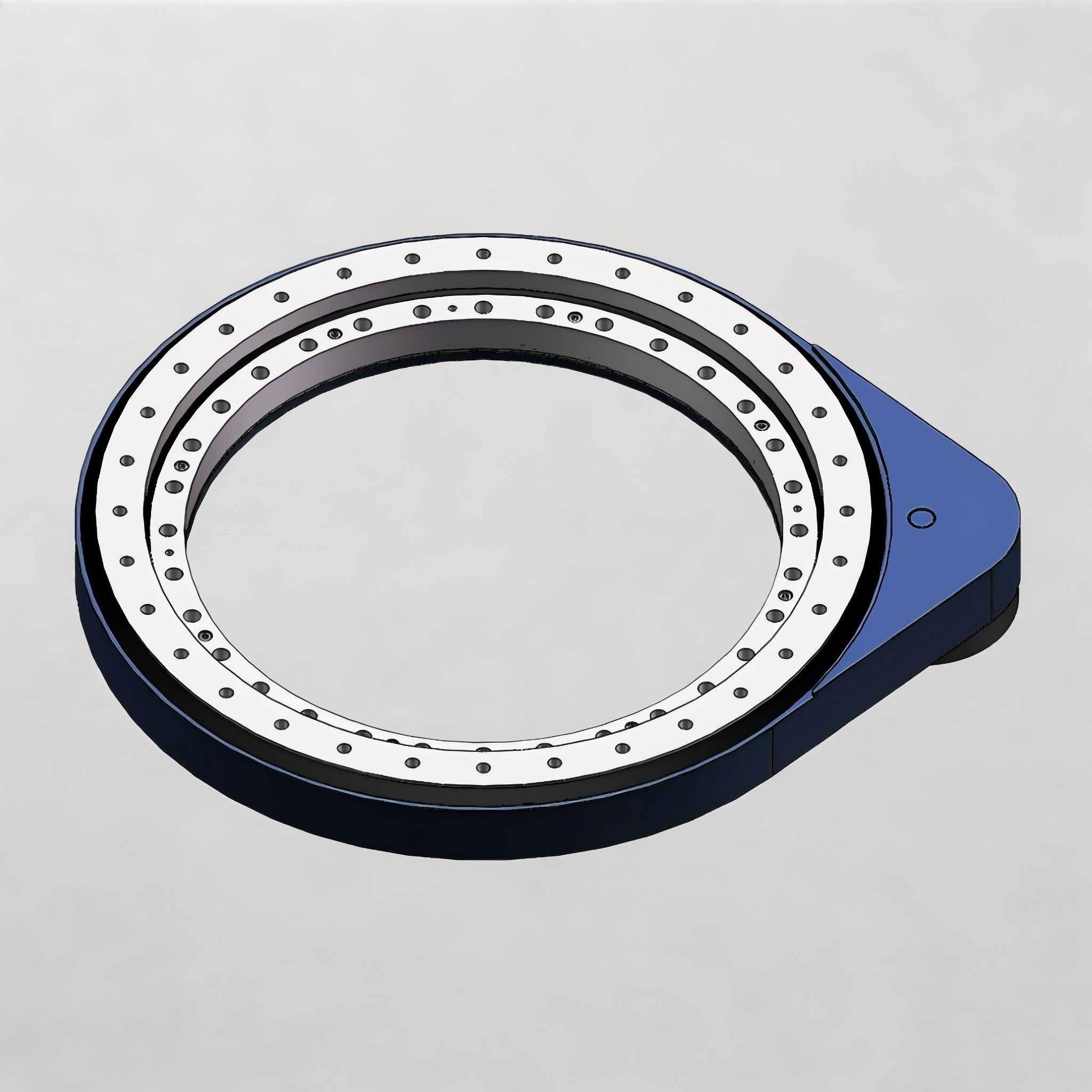

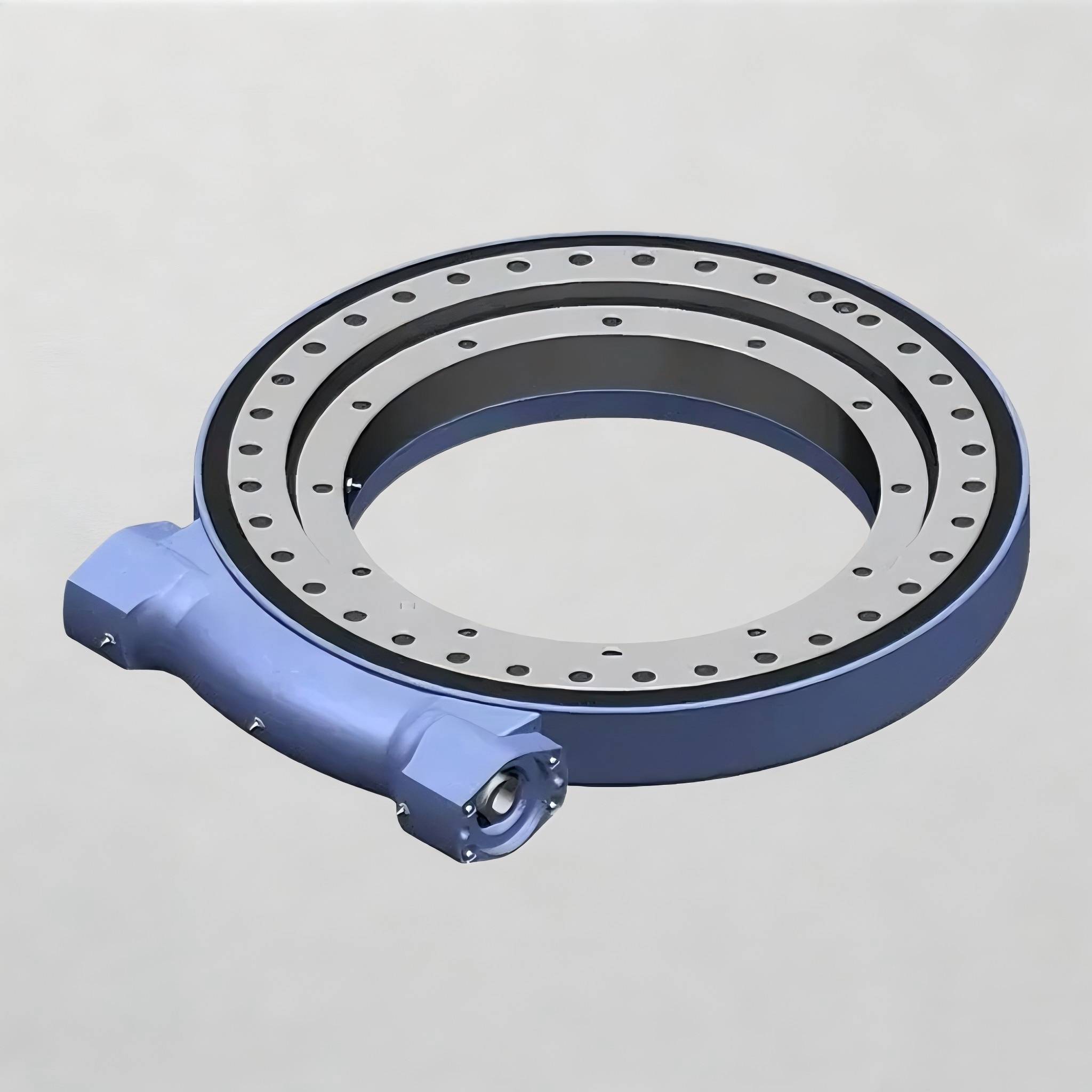

Gear type slewing drive

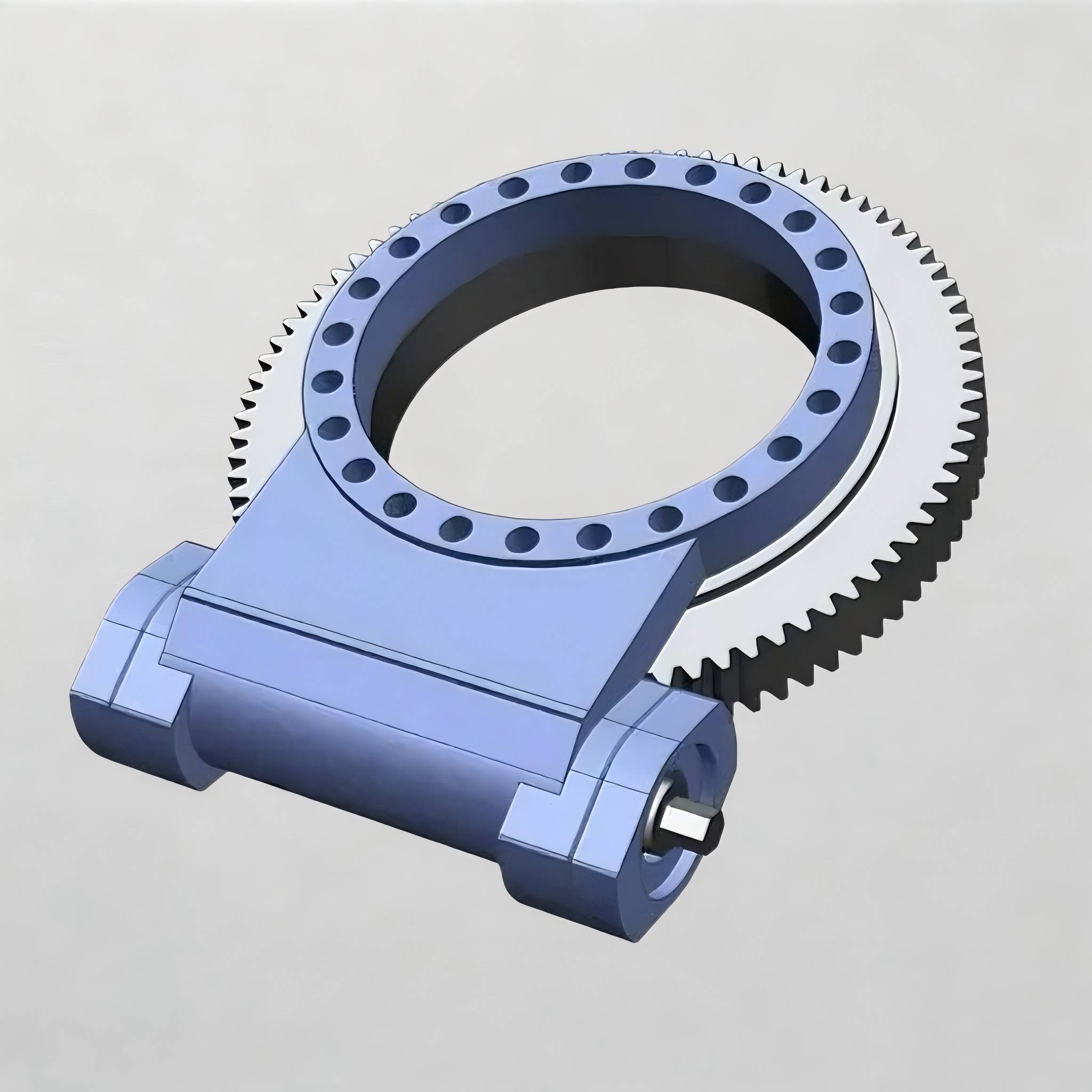

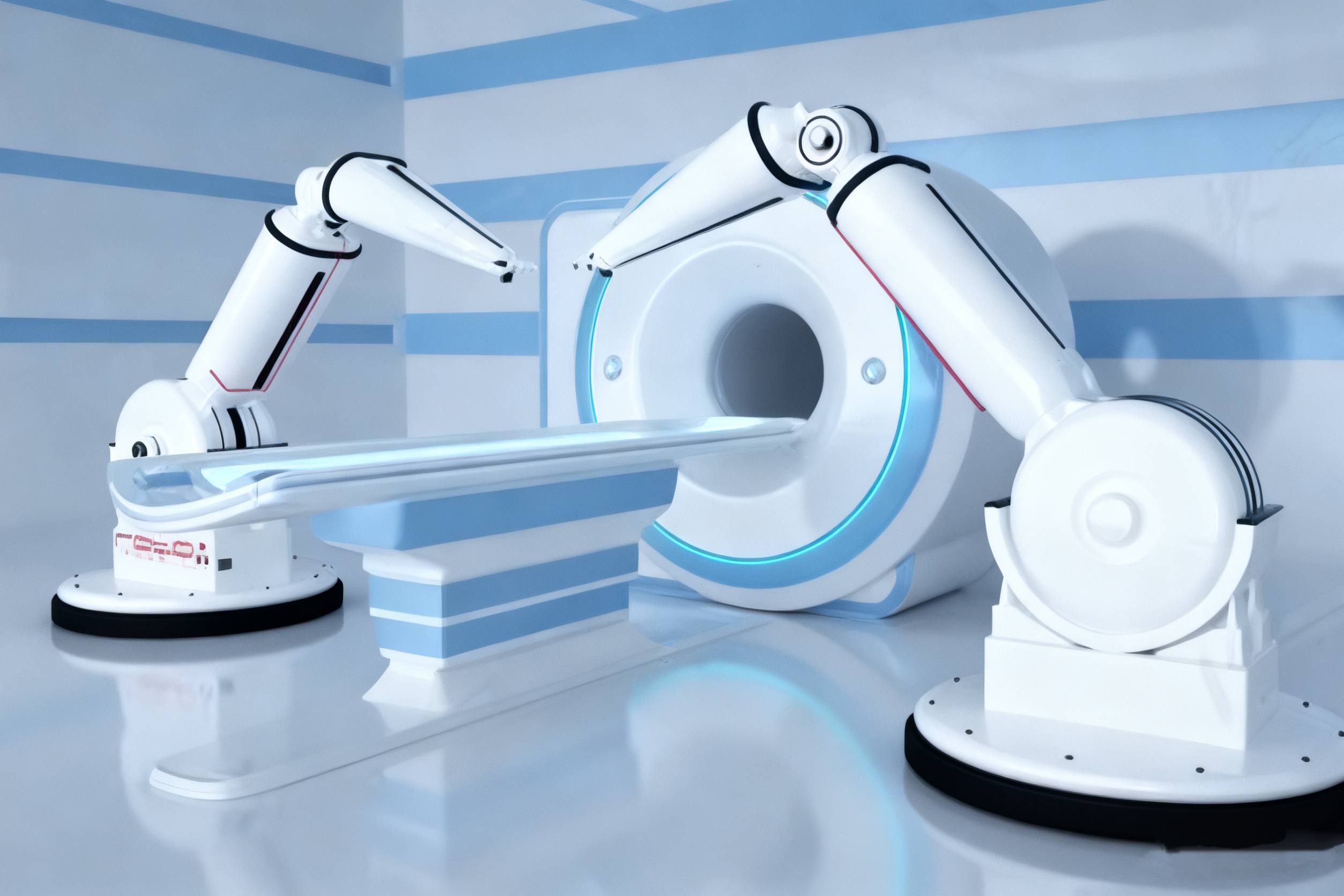

A gear-driven slewing drive is a type of drive mechanism that utilizes spur or helical gears meshing with a slewing bearing gear ring to achieve high-precision rotation. It converts the high speed and low torque of a motor into low speed and high torque 360° rotation. Its core difference from worm gear drives lies in the rigid gear meshing of the transmission pair, which lacks self-locking characteristics. Complementary to worm gear slewing drives, it excels in high transmission efficiency, high-speed adaptability, and heavy load capacity. It is a core rotating component for engineering machinery and heavy equipment, suitable for heavy-duty equipment such as port cranes, tunnel boring machines, rotary drilling rigs, and large industrial turntables.

LTZC Gear type slewing drive advantages

High-efficiency transmission, rapid response

LTZC gear-type slew drives utilize helical/spur gear meshing designs, resulting in high transmission efficiency and fast response, making them suitable for mechanical equipment with high dynamic performance requirements.

Compatible with various motors and reducers

This structure is compatible with servo motors, hydraulic motors, and planetary reducers. LTZC can providehigh-precision slew drives and slewing bearing solutions tailored to project requirements.

Excellent impact resistance and wear resistance

LTZC uses high-strength materials 42CrMo and 50Mn for its gears and employs a quenching process, ensuring stable and reliable operation even under frequent start-stop cycles and impact loads.

LTZC slewing drive quality assurance

LTZC bearings have over 20 years of experience in the R&D of slew ring bearings and slew drives. Their products are certified by ISO 9001, 14001, 45001, CCS, BV, ABS, etc., and are exported to Germany, South Korea, Canada, Spain, and other countries, receiving consistent praise from customers. LTZC also provides warranty periods and technical consulting services.

Gear type slewing drive

| Item | Module (mm) | Teeth number of wheel (Z2) | Teeth number of pinion (Z1) | Gear ratio | Max torque (N·m) | Nom torque (N·m) | Max holding torque (N·m) | Radial static load (kN) | Axial static load (kN) | Radial dynamic load (kN) | Axial dynamic load (kN) | Weight (kg) |

|---|

| SP - I 0229 | 4 | 81 | 15 | 5.4 | 2860 | 2500 | 2860 | 155 | 440 | 145 | 170 | 35 |

| SP - I 0311 | 4 | 102 | 15 | 6.8 | 3580 | 2540 | 3580 | 200 | 530 | 165 | 190 | 42 |

| SP - I 0411 | 4 | 126 | 15 | 8.4 | 4450 | 3205 | 4450 | 265 | 700 | 180 | 215 | 50 |

| SP - I 0541 | 4 | 156 | 15 | 10.4 | 5650 | 4045 | 5650 | 350 | 930 | 205 | 240 | 65 |

| SP - I 0641 | 4 | 183 | 15 | 12.2 | 6550 | 4680 | 6550 | 410 | 1100 | 220 | 255 | 75 |