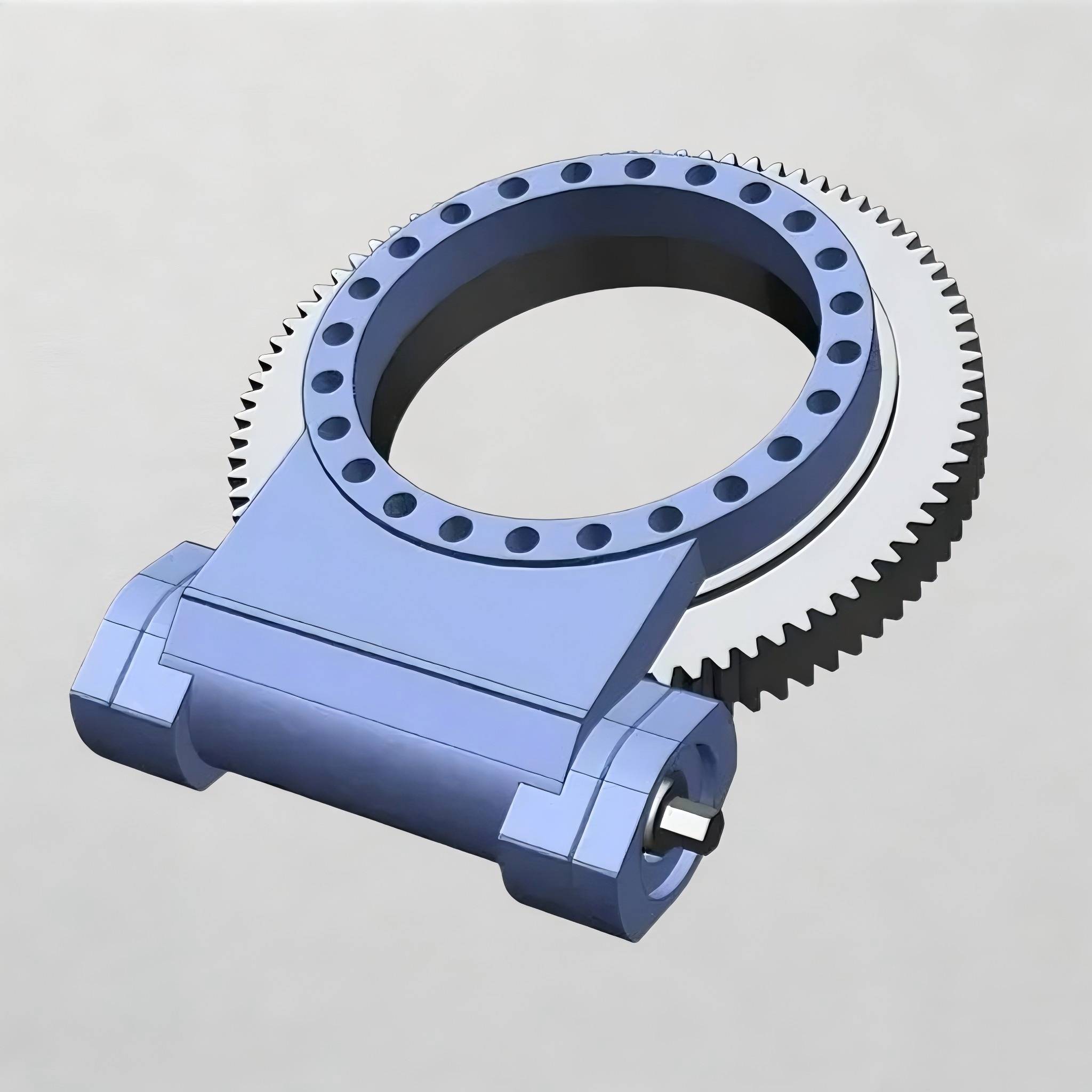

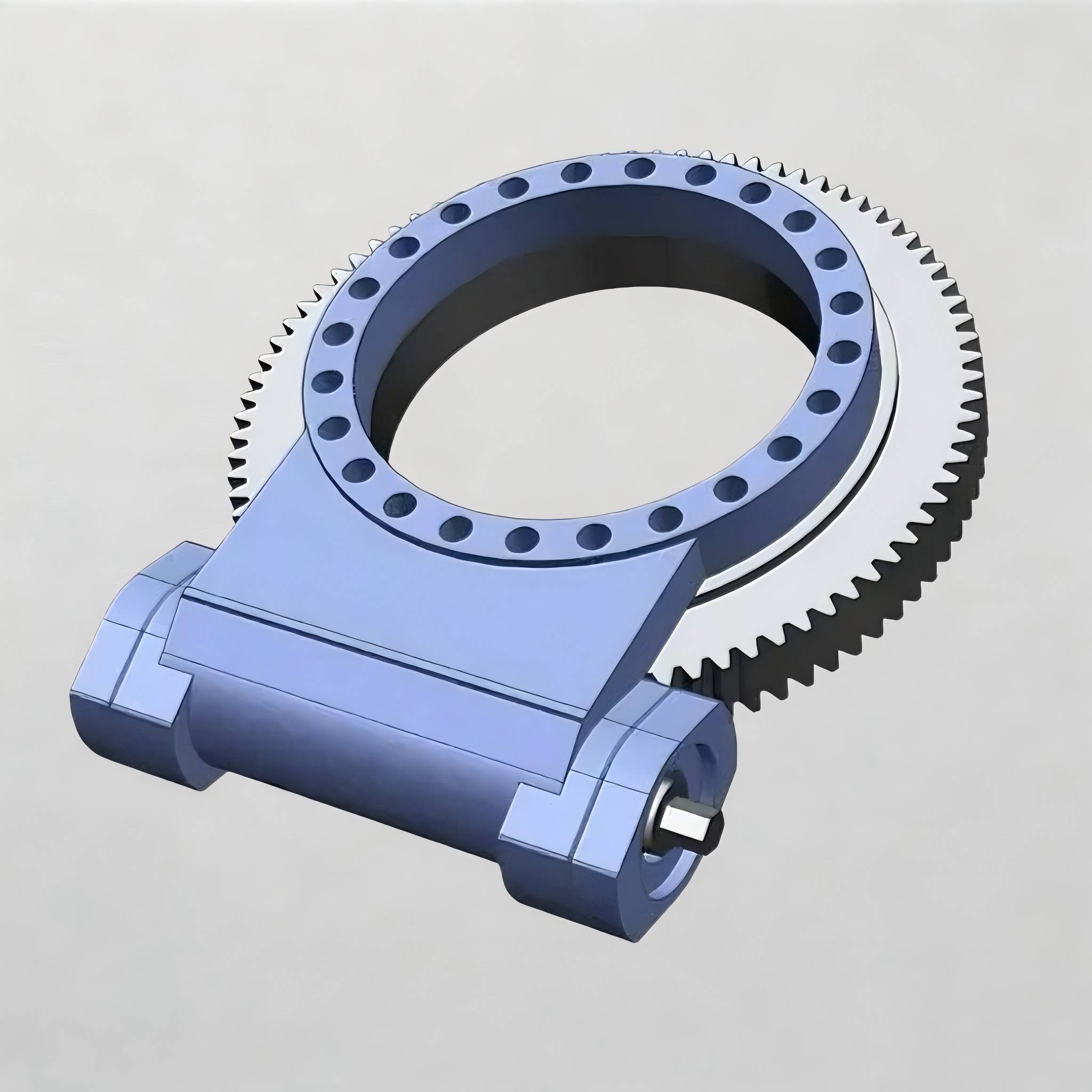

Open Housing Slewing Drive

What is open housing slewing drive?

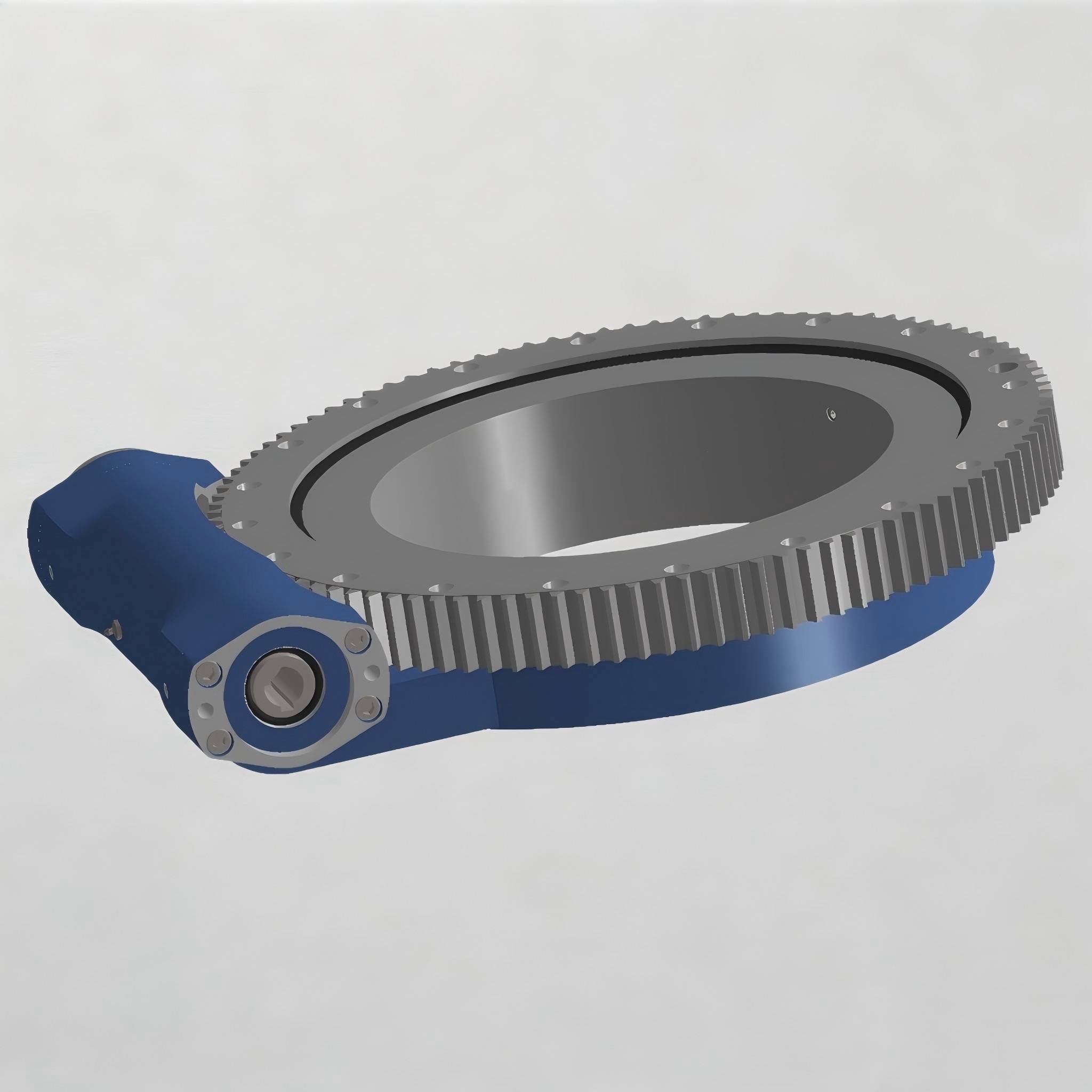

An open-type slewing drive is a type of slewing drive that does not have a completely enclosed housing, allowing the slewing bearing, reduction mechanism, and gears to be visible. The gears are fully exposed to the external environment, and common gear types include spur gears and helical gears. The slewing bearings commonly used in open-type slewing drives include four-point contact ball slewing bearings, three-row roller slewing bearings, and crossed roller slewing bearings, which primarily withstand axial forces, radial forces, and overturning moments. Due to its open design, this type of slewing drive is not limited by housing and worm gear dimensions, allowing for very large transmission torques, making it particularly suitable for large-scale equipment.

Open housing slewing drive advantages

Open-type slewing drives, compared to enclosed slewing drives, are not limited by an enclosed housing, allowing for lower maintenance costs and suitability for light-load, low-speed, and low-precision applications.

Optimized Load Capacity

Thanks to LTZC's advanced precision machining technology, this open-type slewing drive mechanism can achieve ultra-high torque without the limitations of housing and worm gear size, ensuring excellent wear resistance and long-term durability under continuous torque loads.

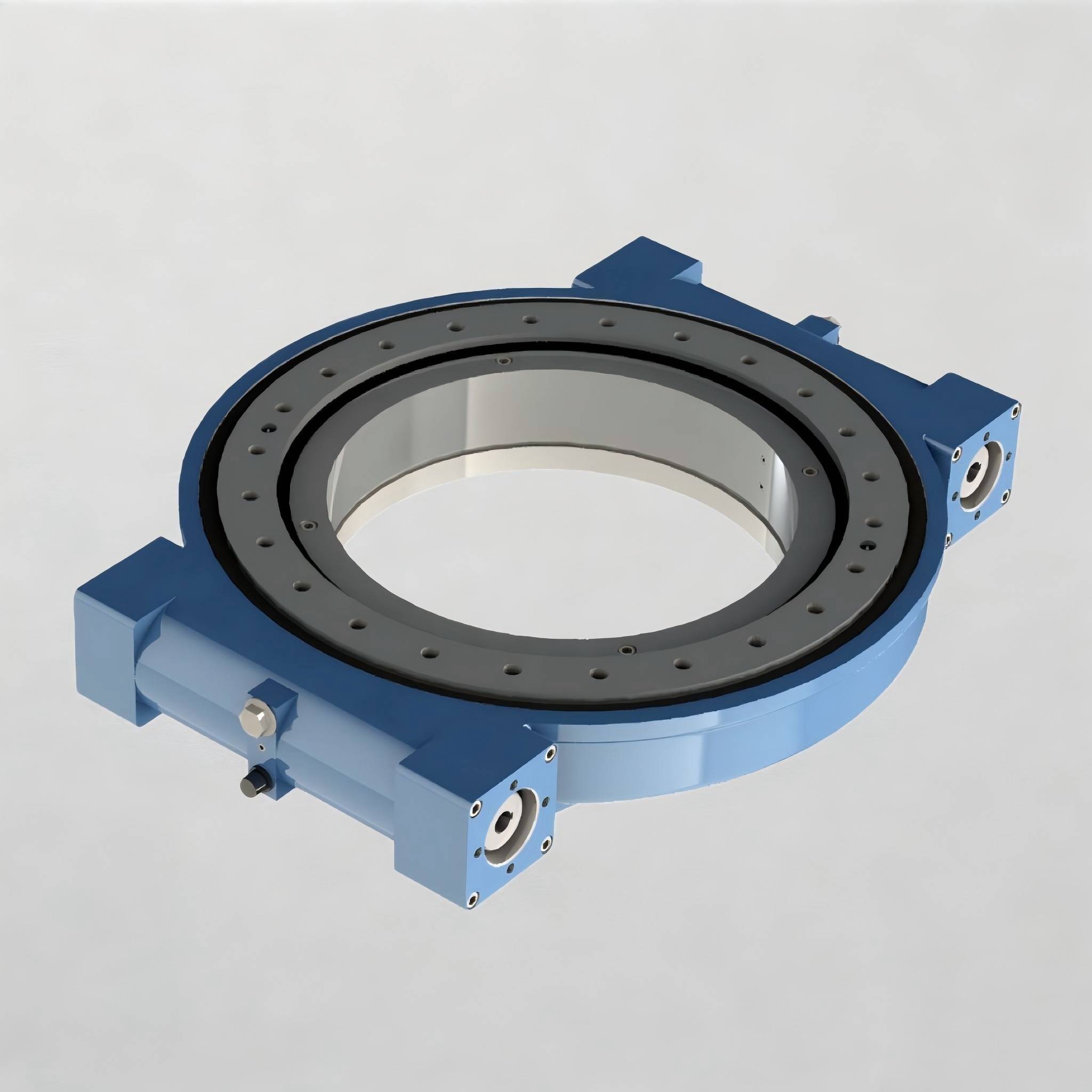

Precision Gear Machining

LTZC utilizes CNC machining and precision grinding processes to achieve: gear accuracy class 7–8 (GB/T 10095), backlash control: 0.10–0.25 mm, resulting in smoother meshing, lower noise, and higher torque transmission efficiency.

Corrosion Resistant and Environmentally Friendly

LTZC open-type slewing drive mechanisms use zinc-nickel coating (≥720 hours salt spray test) and special lubricants, maintaining stable torque output even in harsh environments.

Customized Slewing Drive Solutions

If customers have special technical requirements regarding load, torque, lifespan, etc., the LTZC team can provide customized slewing drive solutions.

Applications

Construction Machinery: Concrete pump trucks, drilling rigs, mast cranes, mini crane platforms

Security Monitoring and Radar Systems: Servo motors, speed reducers, radar antennas, optoelectronic pods

Marine and Offshore Equipment: Offshore work platforms, deck machinery, mini cranes

New Energy and Environmental Protection Equipment: Biomass processing systems, wind direction adjustment mechanisms

Get a quote for LTZC bearings View LTZC quality and certifications View LTZC manufacturing capabilities

S series-Open Housing Slewing Drive

| Model | Gear Ratio | Output Torque (kN·m) | Holding Torque (kN·m) | Overturning Moment (kN·m) | Axial Load (kN) | Radial Load (kN) | Accuracy | Self-locking | Rated Output Speed (rpm) | Weight (kg) |

|---|

| S9 | 61:01:00 | 6.5 | 12 | 33.9 | 45 | 25 | ≤0.2° | Yes | 3 | 42 |

| S12 | 78:01:00 | 7.5 | 15 | 54.3 | 60 | 30 | ≤0.2° | Yes | 2.5 | 48 |

| S14 | 85:01:00 | 8 | 18 | 67.8 | 75 | 35 | ≤0.2° | Yes | 2.3 | 55 |

| S17 | 102:01:00 | 10 | 25 | 135.6 | 120 | 55 | ≤0.15° | Yes | 2 | 87 |

| S25 | 120:01:00 | 16 | 40 | 220 | 200 | 90 | ≤0.1° | Yes | 1.8 | 135 |